5planning the installation, Easy carb flow diagram – Taylor-Wharton EasyCarb User Manual

Page 5

5

Planning the Installation

Consult with your customer, and check local code restrictions, before determining a

location for the unit. The container should be installed in a location away from day to

day activity to minimize tampering. It should be accessible for maintenance and

occasional monitoring.

The fill box should be readily accessible for CO

2

deliveries 24 hours a day. A lock-

able fill box is part of the installation. The fill box location should be within 35-ft.

(10.7m) of the delivery point, due to the limited reach of the delivery vehicle.

For safety and ASME code requirements, the length of the fill line and vent lines from

the fill box to the easycarb™ must not exceed 20-ft. (6m) in length. Consult Taylor-

Wharton for technical assistance when installing longer lines to avoid problems.

A stainless steel surface mounted fill box is most commonly used as it minimizes

modifications to the building and installation time. However, flush mounted fill boxes

are available.

Plan the routing of fill and vent lines. These should be in an area well protected from

accidental damage. If you can’t conceal the lines, mount them to the interior walls, or

secure them to overhead structural members as required by many local codes. Avoid

hot areas if possible.

Do not route easycarb™ lines near steam or hot water lines. For local regulations

that require the cylinder to be elevated from the floor, we offer a platform base. If the

platform base is used to elevate the cylinder; the cylinder must be anchored to a wall

by its handling ring. Part numbers of the platform base and wall anchor can be found

in the Replacement Parts List. It is recommended that appropriate local code approv-

als be reviewed prior to scheduling the installation.

Note:

This container is manufactured

to ASME pressure vessel

specifications. It should not be

used to transport liquid carbon

dioxide. The easycarb™ is

intended to be transported to

the installation site empty and

filled after it is installed.

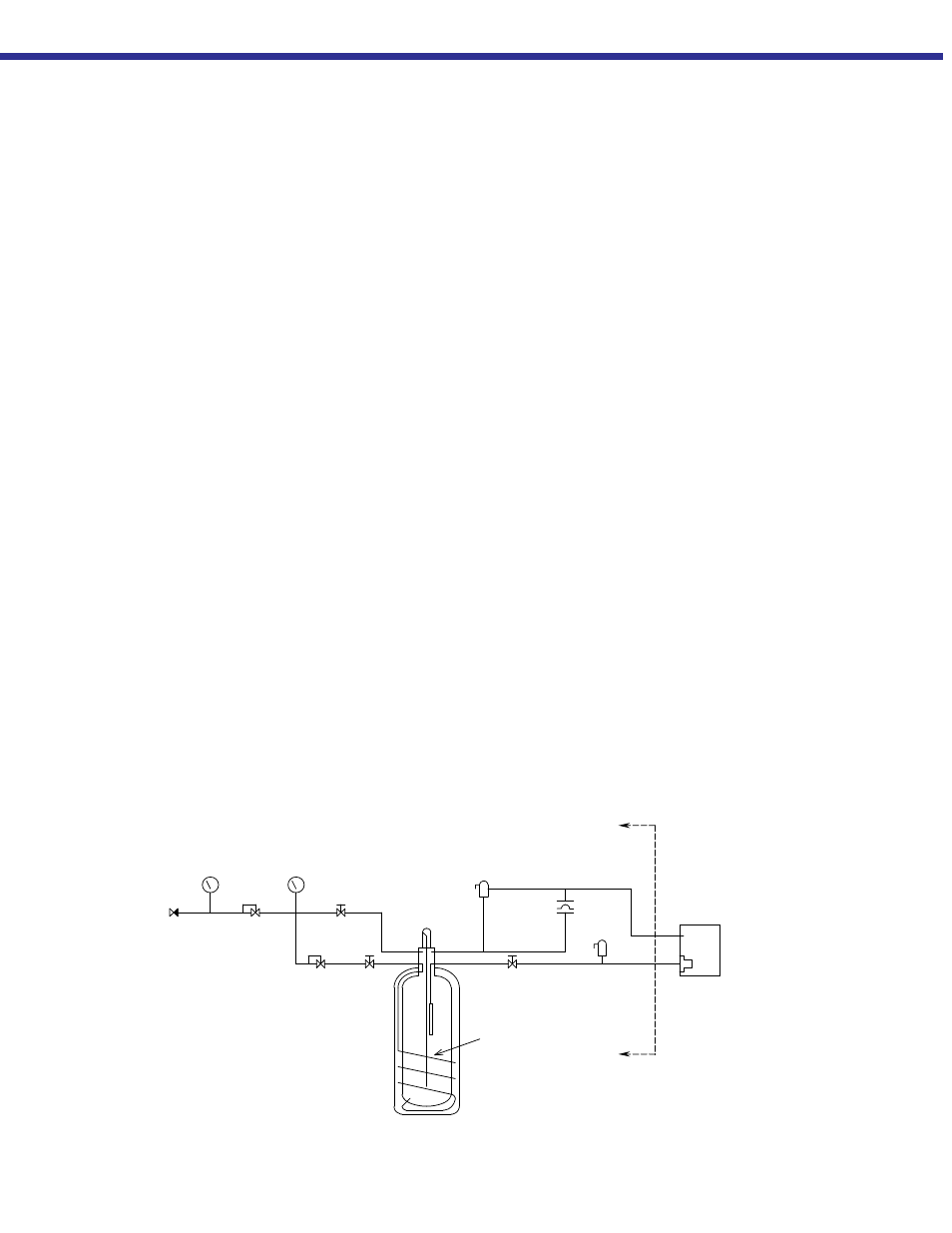

easyCARB Flow Diagram

Fill

Station

Fill

Vent

Inner Container

Safety Head

Fill Valve

Fill Line

Relief Valve

Inner Container

Relief Valve

Isolation

Valve

Pressure

Building

Regulator

Pressure

Building Coil

Isolation

Valve

Container

Pressure

Gauge

Gas Use

Regulator

Supply Line

Pressure Gauge

Check Valve

Supply to Drink

Machine

Liquid Contents

Gauge

Standard

Components

included on all

easyCARB

products