Taylor-Wharton EasyCarb User Manual

Page 11

11

Checking Container Performance

The easycarb™ is basically two containers, one within the other. The space between

the containers acts as a thermal barrier because of high technology insulation and a

vacuum. Each serves a very important part in the useful life of the container. The

insulation is very effective in preventing radiated heat from entering the inner con-

tainer; the vacuum prevents heat convection or conduction from reaching the liquid

contents. When the vacuum in the insulation space is no longer effective, the follow-

ing symptoms may appear:

· When the container is filled with liquid, the outer casing will be much colder than

normal.

· Frost, indicating the liquid level, may be visible on the outer casing of the container.

· The container may appear to "sweat" if the air surrounding the container is hot and

humid.

· The relief valve will open continuously until the container empties prematurely.

Normal Evaporation Rate (NER) Testing. If a loss of vacuum integrity is suspected,

the container's Normal Evaporation Rate should be checked. However, always

perform a visual check of the inner container safety head before proceeding with the

test. If the safety head is ruptured, it must be replaced before performing the test. If

the safety head is intact, take the container out of service and perform the following

test:

The pressure building valve must be closed during the NER test. The container must

be in a well ventilated area where the temperature is approximately 70°F (21°C.)

1. Fill the container until it contains at least 100lb. (45 kg) of liquid for the EC400 and

125 lb. (57 kg) for the EC600.

2. Allow the container to stabilize with all valves closed until it vents through the relief

valve. Weigh the container. Record the weight, time, and date.

3. Reweigh after the container is allowed to vent for 24 hours. Record the weight,

time, and date.

4. If the weight of the carbon dioxide lost in 24 hours is greater than 8lb. (3.6 kg), the

container may have lost its vacuum.

5. If the above test is inconclusive, reweigh again after 48 hours.

The test is most affective if container is not moved during this period.

6. If the total amount of carbon dioxide lost in the 48 hour test

exceeds 17 lb. (7.7 kg), the container may be considered defective.

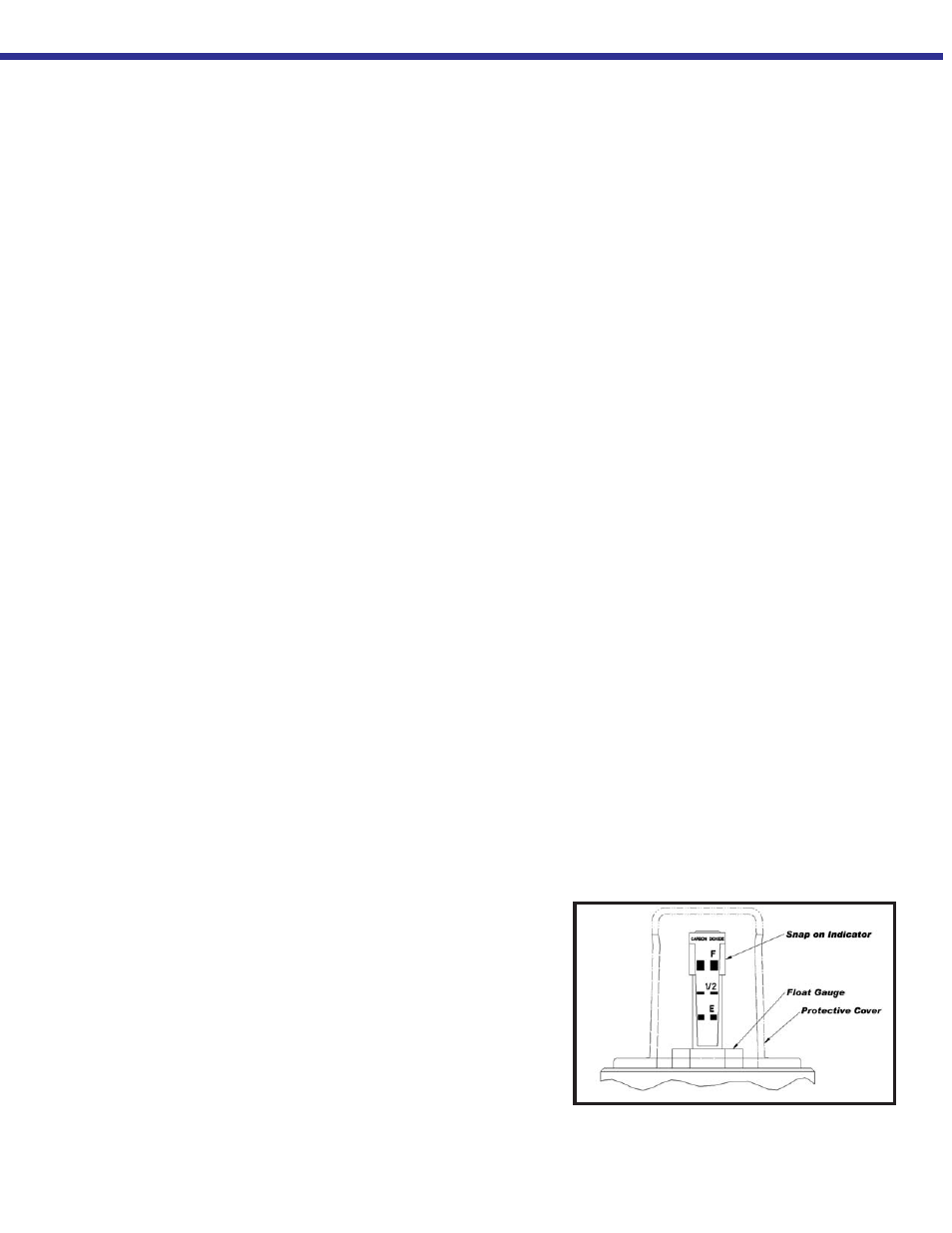

Full View Contents Gauge

The content of these containers is measured with the Full View

Contents Gauge. The device consists of the gauge body and snap

on level indicator. When the gauge is assembled, the indicator is

magnetically coupled to the top of a float rod that moves up or down

with the changing level of liquid in the container.

Note:

See the TROUBLE-

SHOOTING Section for more

detailed symptoms.