Trouble-remedy guide, Trouble-remedy guide 22 – Taylor-Wharton Microbulk Tanks User Manual

Page 24

TW-407 Rev.-

22

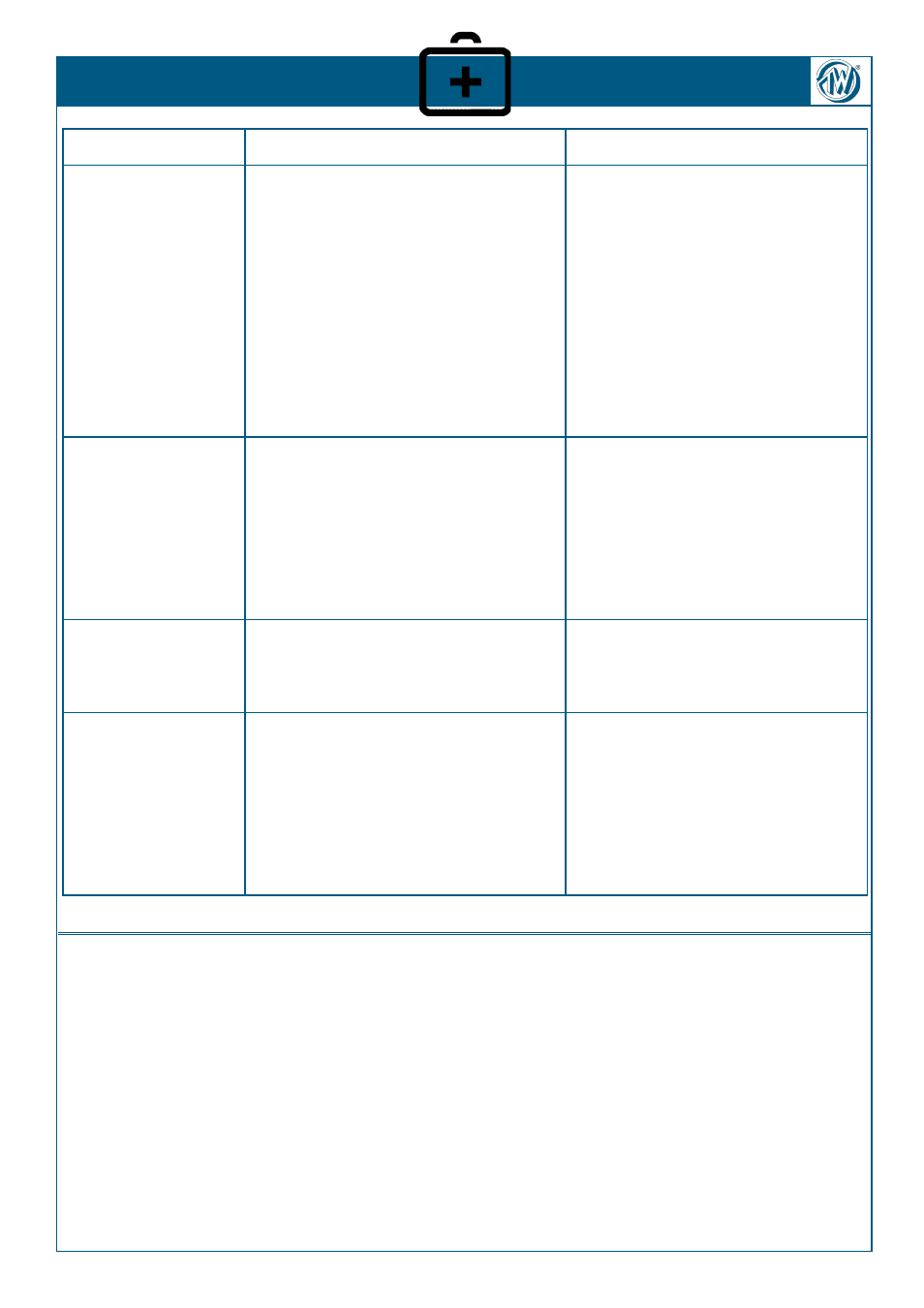

Trouble

Possible Cause

Remedy

Low operating pres-

sure.

a

Safety valve leaking or frozen open.

b

Safety disc ruptured.

c

Piping leaks to atmosphere.

d

Pressure building / economizer regu-

lator malfunction.

e

Excessive product withdrawal.

f

Pressure building valve closed.

g

Malfunctioning pressure gauge.

h

Excessive frost on pressure building

coils.

a

Thaw out valve or replace if neces-

sary.

b

Replace disc.

c

Leak test and repair piping.

d

Adjust regulators. Replace if nec-

essary.

e

Check for leaks downstream. Re-

duce product use.

f

Open pressure building valve.

g

Replace pressure gauge.

h

Thaw pressure-building coils.

Excessive system

pressure.

a

Extensive shutdown time.

b

Low withdrawal rate.

c

Malfunction of pressure-building cir-

cuit.

d

Malfunction of pressure gauge.

e

Bad vessel vacuum.

a

No remedy.

b

No remedy.

c

Adjust pressure-building regula-

tors. Replace if necessary.

d

Replace gauge.

e

Perform NER test. Have vessel re-

paired and re-evacuated if necessary.

Leaking relief valve.

a

Dirt or ice in valve.

b

Damaged valve seat.

a

Thaw out valve. Replace if neces-

sary.

b

Replace valve.

Ruptured pressure

vessel rupture disc.

a

Excessive vessel pressure.

b

Defective rupture disc.

c

Atmosphere corrosion and/or disc

fatigue.

d

Interior disc corrosion.

e

Relief device failed.

a

Excessive system pressure trouble

section. Replace rupture disc.

b

Replace rupture disc.

c

Replace rupture disc.

d

Blow out safety device line. Re-

place rupture disc.

e

Replace relief device and rupture

disc.

TROUBLE-REMEDY GUIDE