Maintenance, Suggested leak test, Maintenance 18 – Taylor-Wharton Microbulk Tanks User Manual

Page 20: Suggested leak test 18

TW-407 Rev.-

18

Routine inspections of the system are recommended. The need for maintenance usually becomes ap-

parent from inspection and indications of improper operation. Typical trouble indications include leak-

age from valves or piping connections and excessive venting through relief valves. Keep a permanent

log of all inspections and repairs performed. Such a log can be valuable in evaluating performance and

scheduling

maintenance.

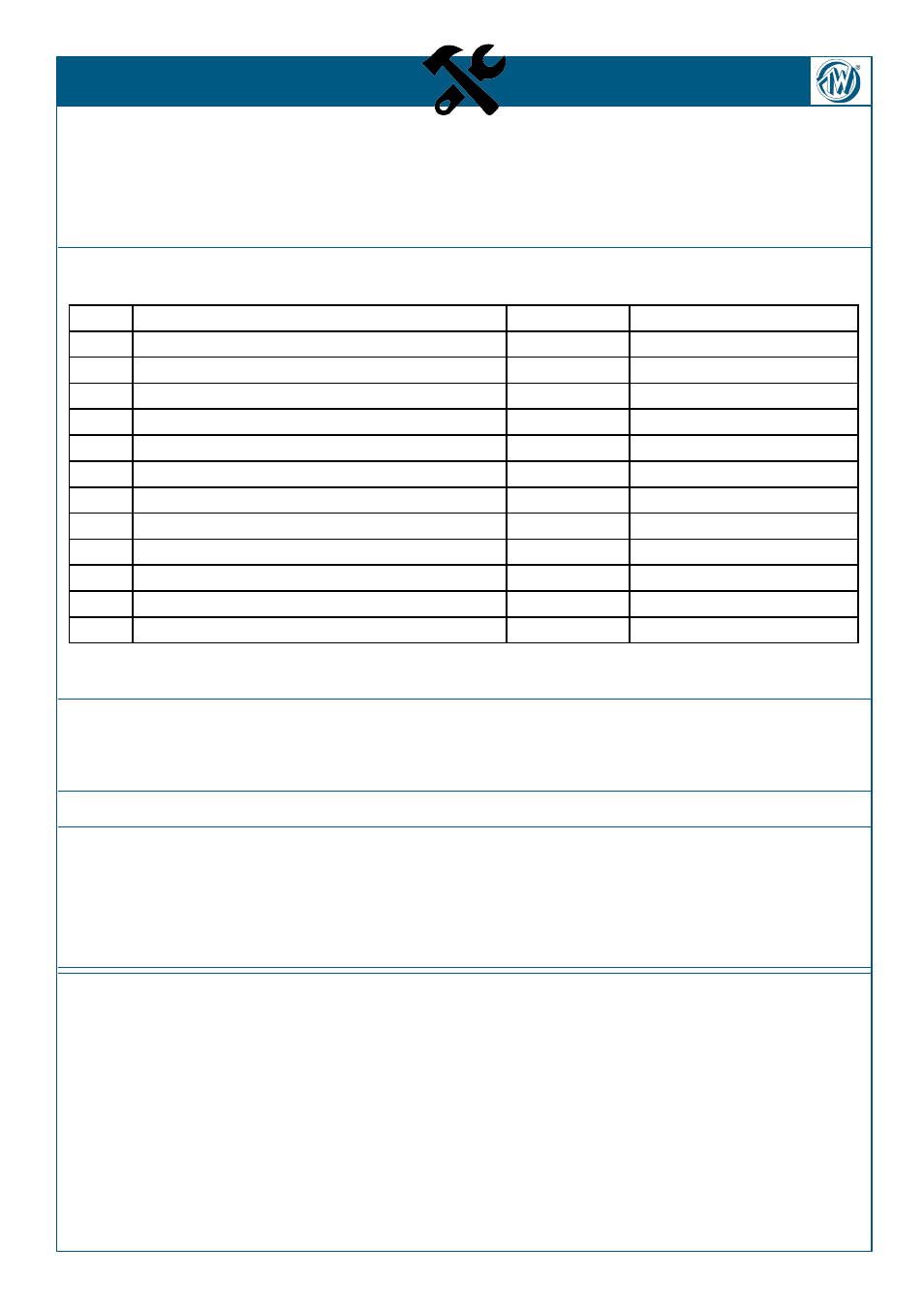

Table 1 1 :

Inspection and Repair Log (Sample Form)

Always observe the safety precautions at the front of this manual and follow the instructions given in

this section. Before working on the system, properly empty the vessel of liquid and relieve pressure on

the vessel and piping. Do not allow unqualified persons to attempt repairs on this equipment. Refer to

the Trouble-Remedy Guide in this manual (page 23) for assistance in troubleshooting.

Suggested Leak Test

After making repairs requiring disassembly or replacement of components, leak test all valves or piping

joints that were taken apart and reconnected. Apply leak detector fluid to the test surface. Large leaks

instantly form large bubble clusters, while fine leaks produce white foam that builds up more slowly. All

leaks must be repaired and retested before the system is returned to service.

Date

Nature of Work (Describe in Full)

Remarks

Service men’s Signature

MAINTENANCE