Chateau™ decorative gas appliance, Gas inlet and manifold pressures, Dvt38s2 certified to – Vermont Casting DVT38S2 User Manual

Page 7: High elevations, Gas line installation, Final finishing, Gas specifications

7

Chateau™ Decorative Gas Appliance

20009543

Gas Inlet and Manifold Pressures

Natural LP (Propane)

Minimum Inlet Pressure

5.5” w.c.

11.0” w.c.

Maximum Inlet Pressure 14.0” w.c.

14.0” w.c.

Manifold Pressure

3.5” w.c.

10.0” w.c.

DVT38S2

Certified To

ANSI Z21.50b-2005 / CSA 2.22b-2005

Vented Gas Fireplace

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1/NFPA 54 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

WARNING: Improper installation, adjust-

ment, alteration, service or maintenance

can cause injury or property damage. Refer

to this manual for correct installation and

operational procedures. For assistance or

additional information consult a qualified

installer, service agency, or the gas supplier.

Gas Line Installation

When purging gas line the front glass must

be removed.

A gas shut off valve must be installed on

the gas pipe line going into the appliance

within easy access.

The gas pipeline can be brought in through the bottom

right side of the valve box assembly.

The gas line connection can be made with properly

tinned 1/2” copper tubing or 1/2” gas tight. Some

municipalities have additional local codes, it is always

best to consult your local authority and the CSA-B149.1

installation codes.

For USA installations consult the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

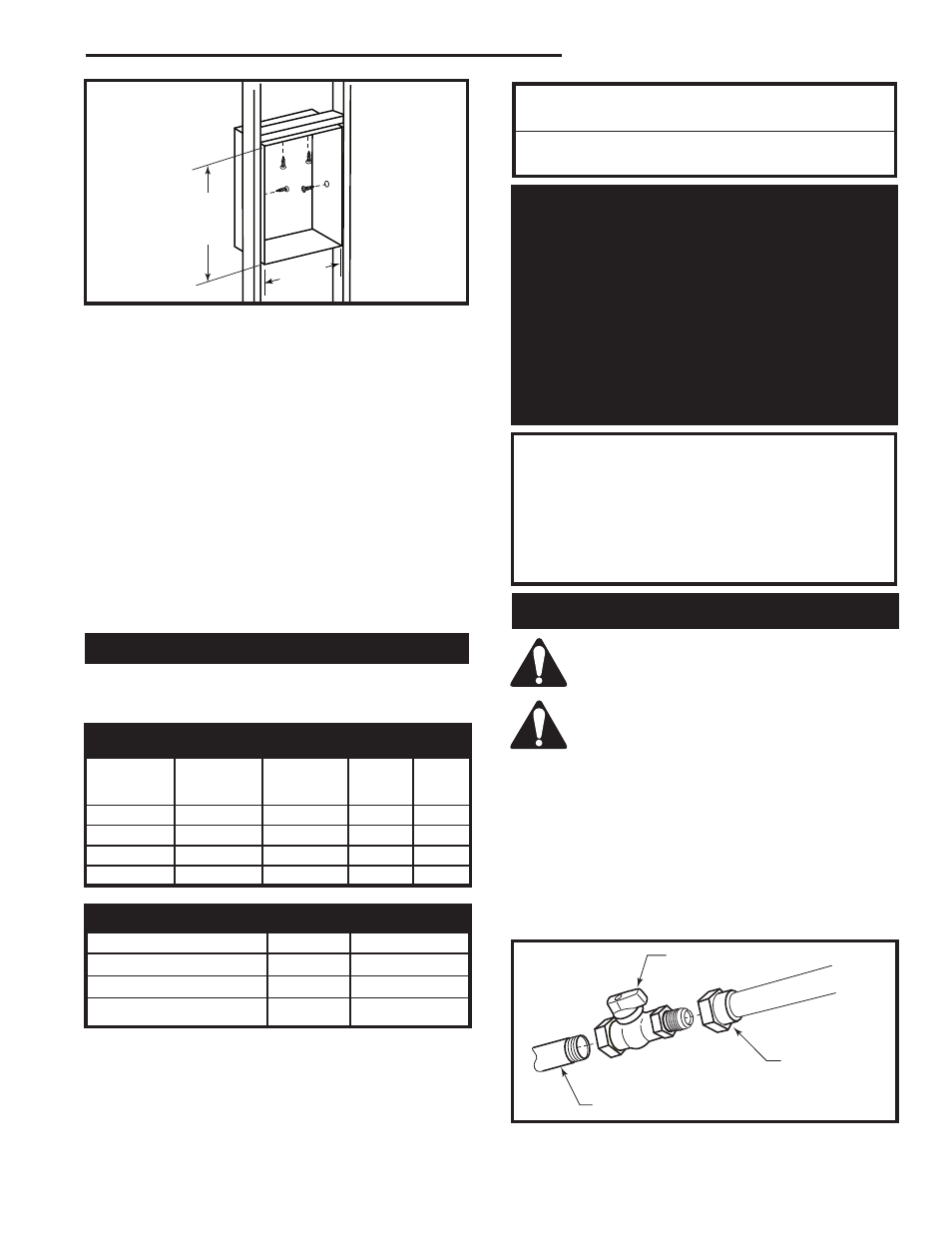

������

���������������

������������������

������

FP297A

1/2” Gas Supply

1/2” NPT X 1/2” Flare

Shut-off Valve

1/2” Gas Tight or

Tinned Copper

(from valve)

(Not provided)

Fig. 8 Typical gas supply installation.

Final Finishing

Noncombustible materials such as brick or tile may be

brought to the edges of the face of the appliance.

������

�������

������

�������

������

���������������������

����������

FP1362

Fig. 7 Valve box framing.

If marble, tile or any other noncombustible decora-

tive face finish material is desired, a 3” (76mm) wide

noncombustible board (recommended Dura-Rock)

is to be nailed to the nailing flanges on both sides

of the unit. Also, 12” (305mm) of noncombustible

board is to be nailed to the front face of the U-chan-

nel and the top framing member above the standoff.

Combustible material can then be brought to the

outside edges of the noncombustible board installed

earlier. Any noncombustible decorative face finish

could be brought to the sides and top of the unit and

can cover the framing and sheet rock. If a decora-

tive facing is not desired, then the noncombustible

boards must be double thickness and brought flush

with the face of the unit.

Gas Specifications

MAX.

MIN.

GAS

INPUT INPUT

MODEL

FUEL

CONTROL

B.T.U.H B.T.U.H.

DVT38S2RN Natural Gas

Millivolt

56,000 38,000

DVT38S2RP

Propane

Millivolt

56,000 45,500

DVT38S2EN Natural Gas 24V Hi/Lo

56,000 38,000

DVT38S2EP

Propane

24V Hi/Lo

56,000 45,500

DVT38S2 Units: GFSN6Q3, GFSE6Q3