Maintenance, Chateau™ decorative gas appliance – Vermont Casting DVT38S2 User Manual

Page 34

34

Chateau™ Decorative Gas Appliance

20009543

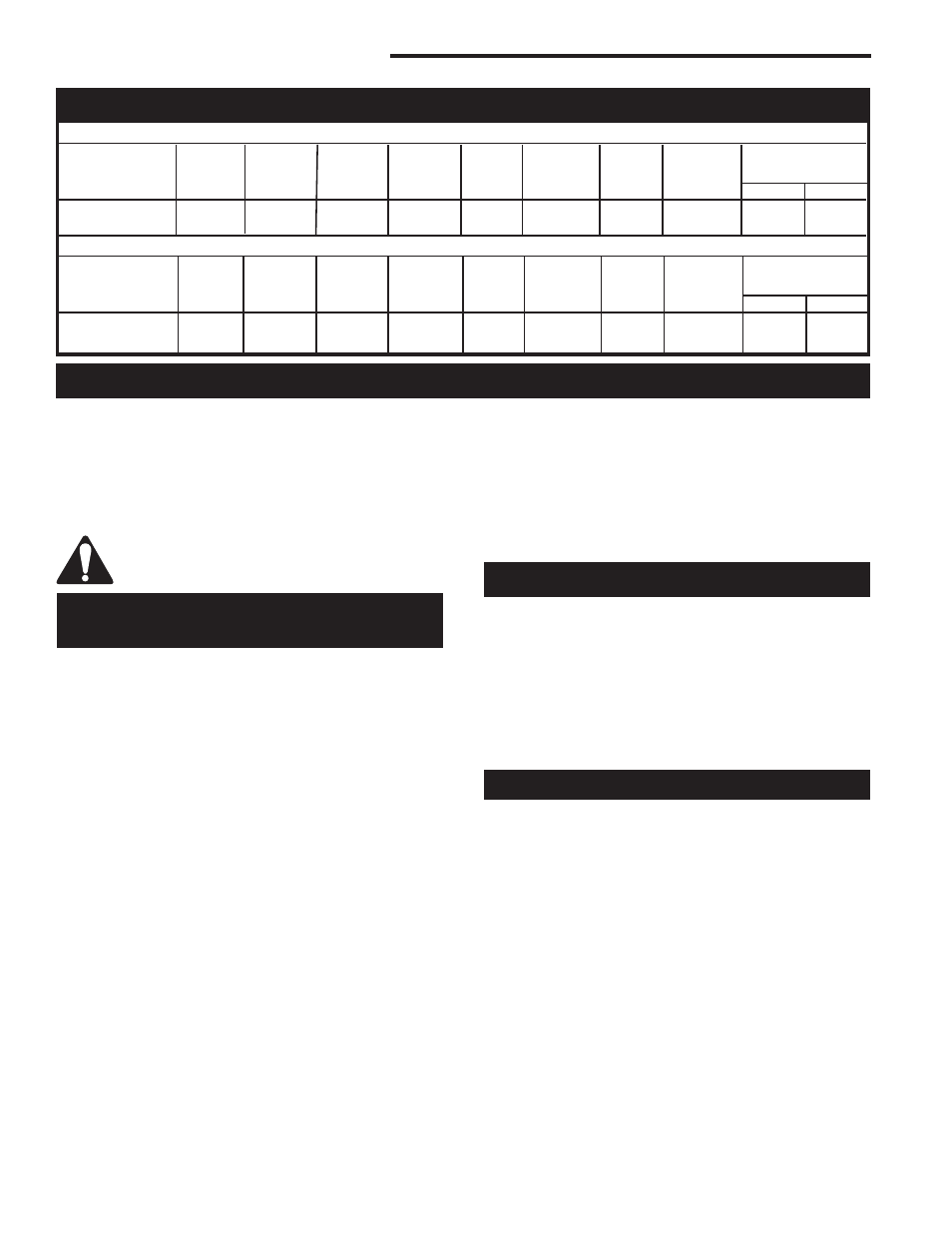

Conversion to Natural Gas

Kit #

Burner

20009164

Burner

Housing/

Burner

Burner

Input (BTU/hr)

Model

Housing

Part #

Pilot*

Part #

Tube

Part #

Tube

Part #

Min.

Max.

DVT38S2RP/EP

#38

20009310

#38

20009310

#45

20010169

#45

20010169 45,000 56,000

(.1015”)

(.1015”)

(.082”)

(.082”)

Table 1 Injector Orifice Size Matrix

Conversion to LP

Kit #

Burner

20009162

Burner

Housing/

Burner

Burner

Input (BTU/hr)

Model

Housing

Part #

Pilot*

Part #

Tube

Part #

Tube

Part #

Min.

Max.

DVT38S2RN/EN

#55

30000333

#54

20000130

#57

20004587

#57

20004587 38,000 56,000

(.052”)

(.055”)

(.043”)

(.043”)

Maintenance

Burner and Burner Compartment

It is important to keep the burner and the burner

compartment clean. At least once per year the logs and

lava rock/ember material should be removed and the

burner compartment vacuumed and wiped out. Remove

and refit the logs as per the instructions in this manual.

Always handle the logs with care as they

are fragile and may also be hot if the

fireplace has been in use.

Cleaning the Standing

Pilot Control System

The burner and control system consist of:

•

burner tube

•

gas orifice

•

pilot assembly

•

thermopile

•

gas valve

Most of these components may require only an

occasional checkup and cleaning and some may

require adjustment. If repair is necessary, it should

be performed by a qualified technician.

1. Turn off pilot light at gas valve.

2. Allow fireplace to cool if it has been operating.

3. Remove window frame assembly. (Refer to Window

Frame Assembly Removal section.)

4. Remove logs.

5. Vacuum burner compartment especially around

orifice primary air openings.

6. Visually inspect pilot. Brush or blow away any dust

or lint accumulation.

7. Reinstall logs.

8. Ignite pilot - Refer to Lighting Instructions.

9. Reinstall window frame assembly.

To obtain proper operation, it is imperative that the pilot

and burner’s flame characteristics are steady, not lifting

or floating.

Typically, the top 3/8” to 1/2” of the thermopile/sensing

electrode should be engulfed in the pilot flame. (Refer

to Page 26, Figure 54)

To adjust pilot burner: (by qualified service technician)

1. Remove pilot adjustment cap

2. Adjust pilot screw to provide properly sized flame.

3. Replace pilot adjustment cap.

Cleaning Electronic Ignition System

The Electronic Ignition burner/control system consists

of:

• main burner

• gas orifice

• pilot burner

• 24VAC valve with transformer

Taking care of the Electronic Ignition units is identical to

taking care of the Standing Pilot models.

Battery Replacement for Ignitor Module

1. Open control panel box door.

2. Remove the extension knob(s).

3. Remove the valve cover by removing the two (2)

screws securing the valve cover plate to the box.

While holding the valve cover plate with one hand,

disconnect the wiring to the switch and the pilot

indicator. NOTE: Do not allow the valve cover plate

to hang from the pilot indicator wires as this could

damage the wires.

4. Replace the battery (AA) in the ignitor module lo-

cated at the top left corner.

5. Replace wires, valve cover, extension knob(s) in

reverse order. NOTE: The pilot indicator body is

labelled +/-, make sure the positive wire on the pilot

indicator goes to ground and the negative goes to

the plug between the valve and the thermocouple.