Chateau™ decorative gas appliance – Vermont Casting DVT38S2 User Manual

Page 17

17

Chateau™ Decorative Gas Appliance

20009543

Vertical Through-the-Roof

Applications

Use of Restrictor Plate

for Vertical Venting Application

The primary purpose for the vent restrictor is to regain

flame height under certain venting conditions as

outlined below.

NOTE: The joints of the inner pipe (flue pipe) must be

taped with 550°F or higher temperature metal adhesive

tape that meets the requirements of F.A.R. 25.853(a).

High temperature sealant milpack or stove cement

of 550°F or higher could be used instead. The joints

of The outer pipe (fresh air pipe) must be taped with

315°F or higher temperature metal adhesive tape or the

use of high temperature milpack or stove cement would

be applicable. When using the unitized 30°, 45° or 90°

elbows, apply 1/4” bead of high temperature, 550°F or

higher, sealant (milpack or stove cement) to the joint of

the inner pipe (flue pipe) and the straight section as it is

impossible to be taped. The outer pipe must be taped

with 315°F high temperature metal adhesive tape for

proper sealing.

For vertically venting either propane or natural gas

units, with vertical vent heights of 12’ (3.7m) or greater,

(measured from the top of the flue collar) the restrictor

plate as supplied with this unit should be used. (Fig.

28) Refer to Page 21, Figure 37 for restrictor plate

installation.

X

FP1461

Fig. 28 Restrictor plate use in straight up installation.

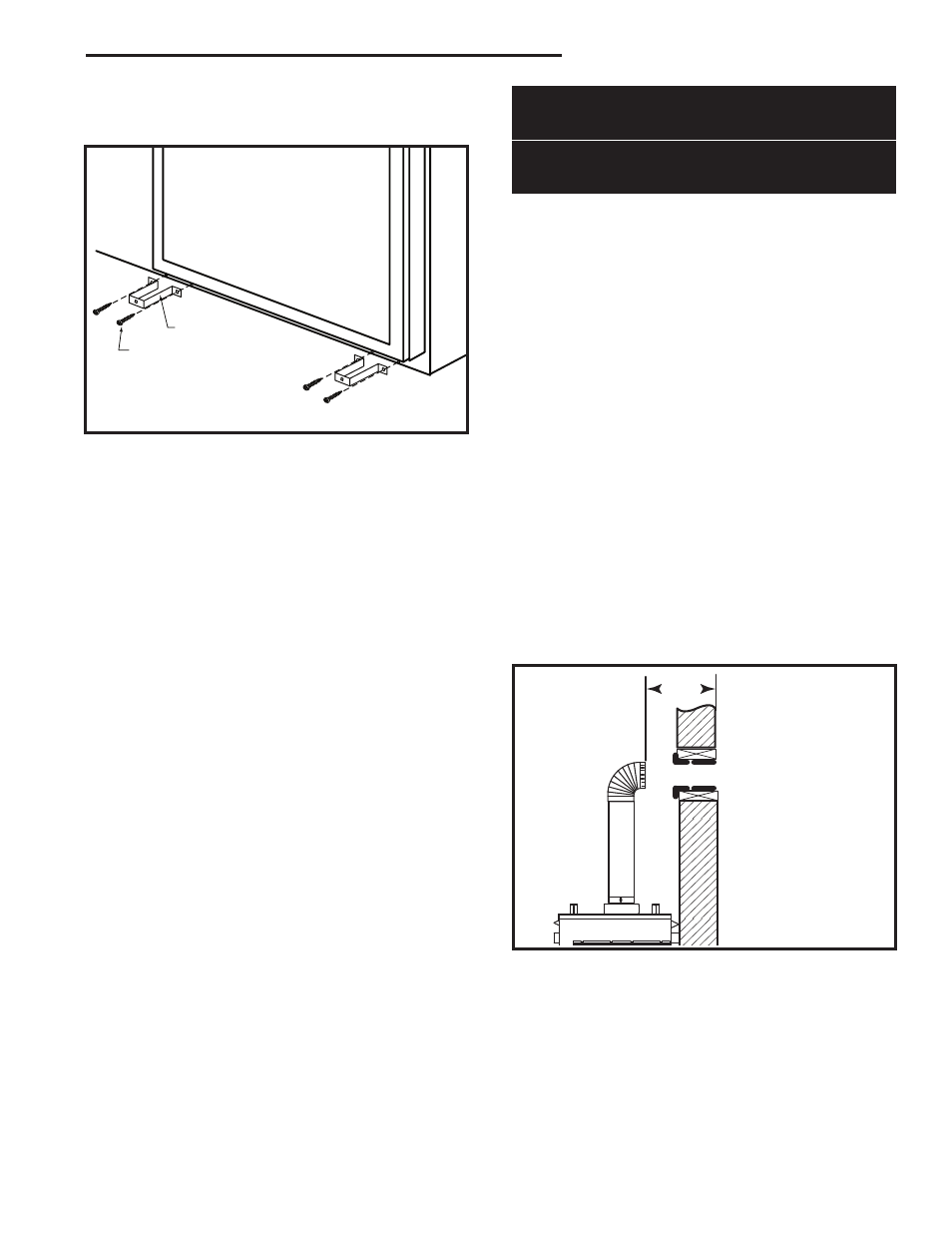

2. Install the two (2) brackets, using the sheet metal

screws, at the bottom right and left corners of the

unit. (Fig. 27)

FP1481

install brackets

4/04

Bracket

Sheet Metal

Screws

FP1481

Fig. 27 Use sheet metal screws to attach brackets to existing

holes under glass frame assembly.

3. Set the glass frame assembly provided with your kit

in front of the glass frame assembly on the unit (the

outside side).

4. Have the machine screws provided with the kit within

reach.

5. Unfasten the two (2) machine screws that secure the

glass frame assembly to the unit and discard. Slide

the glass frame assembly provided with the kit over

the surround around the glass frame assembly on

the side and top.

WARNING: The glass frame assembly provided with

the unit must be left in place for proper operation.

Failure to do so could cause property damage and

malfunction of the unit.

6. Fasten the two (2) long machine screws at the top

through the two (2) glass frame assemblies and fas-

ten the two (2) short machine screws at the bottom

right and left corner into the bracket installed earlier.