Step 4 — rig and place unit, Step 5 — make condensate piping connec- tions, Step 6 — install ductwork – Carrier ROOMTOP 50AH024-096 User Manual

Page 8

8

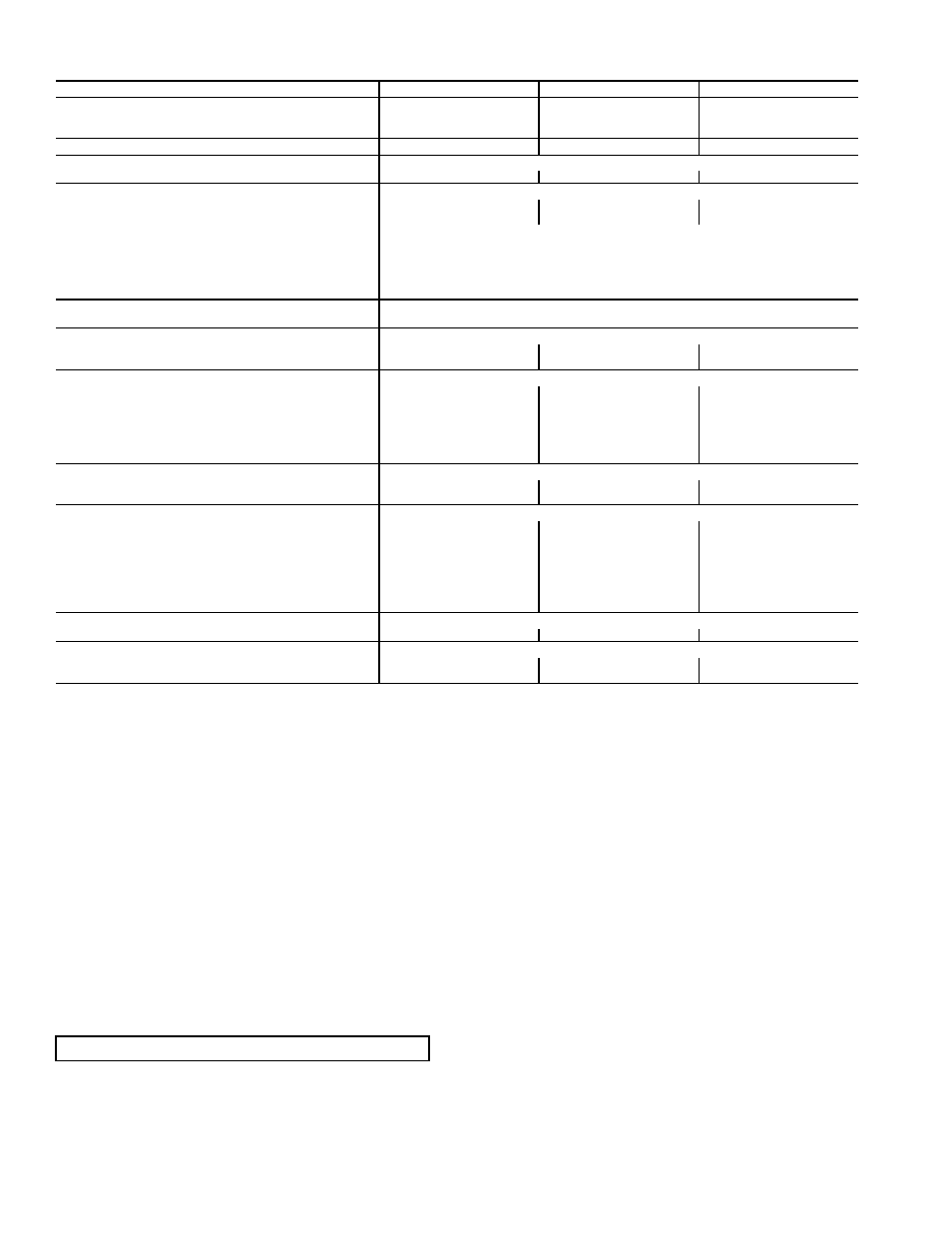

Table 1 — Physical Data (cont)

LEGEND

*Shipping weights include base unit plus packaging.

†If components are to be split, additional refrigerant will be needed.

NOTE: If components are to be split, the maximum length of refrigerant

tubing to be used is 50 equivalent ft, assuming components will be

installed in same horizontal plane. If components are not to be installed

in same horizontal plane, contact your Carrier representative for more

information. For additional piping information, refer to Carrier System

Design Manual, Part 3.

Step 4 — Rig and Place Unit —

Move and store unit

in horizontal position. Provide space around unit for service,

filter access, ductwork, and overhead clearance as indicated in

Fig. 2-5.

Using suitable hydraulic lift source, raise unit up to meet

bottom of the 8 threaded rods suspended from ceiling (12 rods

for units with air-side economizer). Center unit so that the 8 or

12 threaded rods can be easily inserted into the factory-drilled

holes at each end. Refer to Fig. 6 for rigging details.

Apply washers and locknuts on ends of each of the 8 or 12

rods.

Tighten locknuts sufficiently so that unit weight is support-

ed entirely by the 8 or 12 rods. Level unit within the space by

adjusting locknuts.

NOTE: For split systems, 8 (or 12) suspension rods are

required (4 for each section and 4 for economizer if required).

Refer to Splitting Systems section below.

Step 5 — Make Condensate Piping Connec-

tions —

One

7

/

8

-in. OD pipe thread condensate drain con-

nection is provided for the evaporator section.

Step 6 — Install Ductwork —

Use flexible ductwork

to attach duct to unit and to help control transmission of vibra-

tions to building structures. Attach ductwork to the return and

supply ends of both coils.

If unit is located with condenser close to outside of building,

install a field-supplied rainhood. Hood intake dimensions

should be same as condenser return-air dimensions. In addi-

tion, install a triple-layer bird screen over rainhood intake to

eliminate possibility of insects, birds, water, or debris from

entering unit. Ensure hood and/or louvers are installed correct-

ly to avoid condenser air recirculation.

Step 7 — Split Systems (Factory Option, if

Required) —

The Roomtop

®

50AH units may be split into

2 sections, if desired, with condensing section mounted

remotely horizontally. The unit must be ordered with the

“Splittable” cabinet type as shown in the unit model number

nomenclature. See Fig. 1. All splittable units come with the

interconnecting tubing kit.

Sections installed in the same horizontal plane may be sepa-

rated by up to 50 equivalent ft of tubing. Use type L copper or

better.

UNIT 50AH

060

072

096

OPERATING WEIGHT (lb)

Base Unit

960

1214

1283

Evaporator/Condenser Sections

421/519

554/634

556/701

SHIPPING WEIGHT (lb)*

1093

1647

1716

REFRIGERANT TYPE

R-410A

Operating Charge (lb-oz)†

8-8

6-6

6-6

COMPRESSOR — TYPE

Scroll

Quantity...Model

1...ZPKP51K5E

2...ZP31K5E

2...ZP38K5E

Oil (oz)

42

25

42

HPS Setting (psig)

Cutout

650 ± 7

Reset

Manual Reset

LPS Setting (psig)

Cutout

75 ± 7

Reset

100 ± 7

CONDENSATE DRAIN CONNECTION

Size (in.)...Type

7

/

8

...OD

CONDENSER COIL

Copper Tubes — Aluminum Fins

Size (L x H) (in.)

90 x 30

40 x 30 (2 coils)

40 x 30 (2 coils)

Number of Rows...Fins/in.

2...12

2...20

2...20

CONDENSER FAN

Centrifugal — Belt Drive

Nominal Cfm

3000

5200

6400

Blower Size (in.)

15 x 15

18 x 18

18 x 18

Motor Hp (Rpm)

Standard Motor

0.33 (1725)

1.00 (1725)

1.50 (1725)

Upgrade 1 Motor

0.50 (1725)

1.50 (1725)

2.00 (1725)

Upgrade 2 Motor

0.75 (1725)

—

3.00 (1725)

EVAPORATOR COIL

Copper Tubes — Aluminum Fins

Size (L x H) (in.)

32 x 26

46 x 28

46 x 28

Number of Rows...Fins/in.

3...14

3...14

3...14

EVAPORATOR AIR FAN

Centrifugal — Belt Drive

Nominal Cfm

2000

2400

3200

Blower Size (in.)

12 x 9

15 x 15

15 x 15

Motor Hp (Rpm)

Standard Motor

0.33 (1725)

0.50 (1725)

0.75 (1725)

Upgrade 1 Motor

0.50 (1725)

0.75 (1725)

1.00 (1725)

Upgrade 2 Motor

0.75 (1725)

1.00 (1725)

1.50 (1725)

Upgrade 3 Motor

1.00 (1725)

1.50 (1725)

2.00 (1725)

INDOOR-AIR FILTERS

Factory-Supplied Disposable Type

Number...Size (in.)

2...18 x 24 x 1

2...20 x 25 x 1

2...20 x 25 x 1

INTERCONNECTING TUBING SIZE

Suction (Qty...in.)

1...

7

/

8

1...

5

/

8

1...

7

/

8

Liquid (Qty...in.)

1...

3

/

8

1...

3

/

8

1...

7

/

8

HPS — High-Pressure Switch

LPS

— Low-Pressure Switch

IMPORTANT: Unit must be level to operate properly.