Step 8 — make electrical connections, Step 9 — adjust fan speed – Carrier ROOMTOP 50AH024-096 User Manual

Page 10

10

of the tubing. Use a

1

/

4

-in. hole to mount the valve. Clean

and debur the tubing before doing any brazing to ensure

that no chips or debris are left in the refrigerant circuit.

Remove the Schrader valve cap and core before doing

any brazing.

5. After brazing the tubing to the self-sealing coupling

halves, evacuate each line to 500 microns. Check to make

sure that each line holds a vacuum after removal of the

vacuum pump (indicating no leaks). Add the appropriate

charge of R-410A refrigerant using the Schrader valves.

Refasten male halves to outer back panel of evaporator

section with flanges and screws (if they were removed for

brazing to tubing). Wipe off coupling seals and threaded

surfaces with a clean cloth to prevent the inclusion of dirt

or foreign material into the system. Lubricate rubber seal

and metal seal in the male halves with refrigeration oil.

Thread coupling halves together by hand to ensure proper

mating of threads. Continue to handthread each half-cou-

pling to its mating half until resistance is felt (approxi-

mately 1

1

/

2

to 1

3

/

4

turns). Complete the connection of the

mating half-couplings with a wrench. The suction line

couplings (size 12) will be totally engaged after an addi-

tional 5

1

/

2

to 5

3

/

4

turns. The liquid line couplings (size 8)

will be totally engaged after an additional 4

1

/

2

to 4

3

/

4

turns. Use a backup wrench to prevent the couplings from

twisting.

6. Refrigerant piping must be insulated in accordance with

local codes and/or applicable ASHRAE standards. Insu-

lation exposed to weather must be suitable for outdoor

use. Provide protection from water and shielding from so-

lar radiation as necessary.

7. Add refrigerant to the system to compensate for the addi-

tional interconnecting tubing. The suction line should be

pitched downward to the compressor, sloping approxi-

mately

1

/

4

-in. every 10 ft to facilitate oil return. P-traps

(field supplied) are required for all suction line risers ev-

ery 15 ft. When the evaporator is above the condensing

section, an inverted P-trap should be incorporated as

close as possible to the evaporator (this minimizes flood-

back/oil slugging during the off cycle). If the condensing

section is more than 50 ft above the evaporator, consult

Carrier for specific refrigeration components.

Step 8 — Make Electrical Connections —

Con-

nect power wiring to junction box located on unit side near

control box access panel. All wiring must comply

with National Electrical Code (NEC) and all local code

requirements.

Operating voltage to compressor must be within voltage

range as indicated on unit nameplate. On 3-phase units, volt-

ages between phases must be balanced within 2% and current

must be balanced within 10%. Contact local power company

for correction of improper voltage or phase imbalance. Unit

failure as a result of operation on improper line voltage or ex-

cessive phase imbalance constitutes abuse and may cause dam-

age to electrical components. Such operation would invalidate

any applicable Carrier warranty.

Install a fused disconnect per NEC. Refer to unit nameplate

and Tables 2A-2L for fuse sizes and wire amperages for all

units.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation

instructions provided by thermostat manufacturer. Locate

thermostat assembly on a solid wall in the conditioned space

away from drafts to sense average room temperature.

Using thermostat cable or equivalent single leads of no. 18

AWG (American Wire Gage) colored wire, route cable or wire

from the subbase terminals, up and through connector on unit

side (below power lead junction box) and connect to low-volt-

age terminal block inside the control box.

THERMOSTAT WIRE — Use 18 gage for 0 to 50-ft long

wires and 16 gage for 51 to 75-ft wire lengths.

Step 9 — Adjust Fan Speed —

Adjust fan speed to

meet jobsite conditions. Refer to Tables 3 and 4 to determine

fan speed settings. See Service section of this document for

instructions to adjust fan speed.

The evaporator and condenser fan motors on all units are

belt drive.

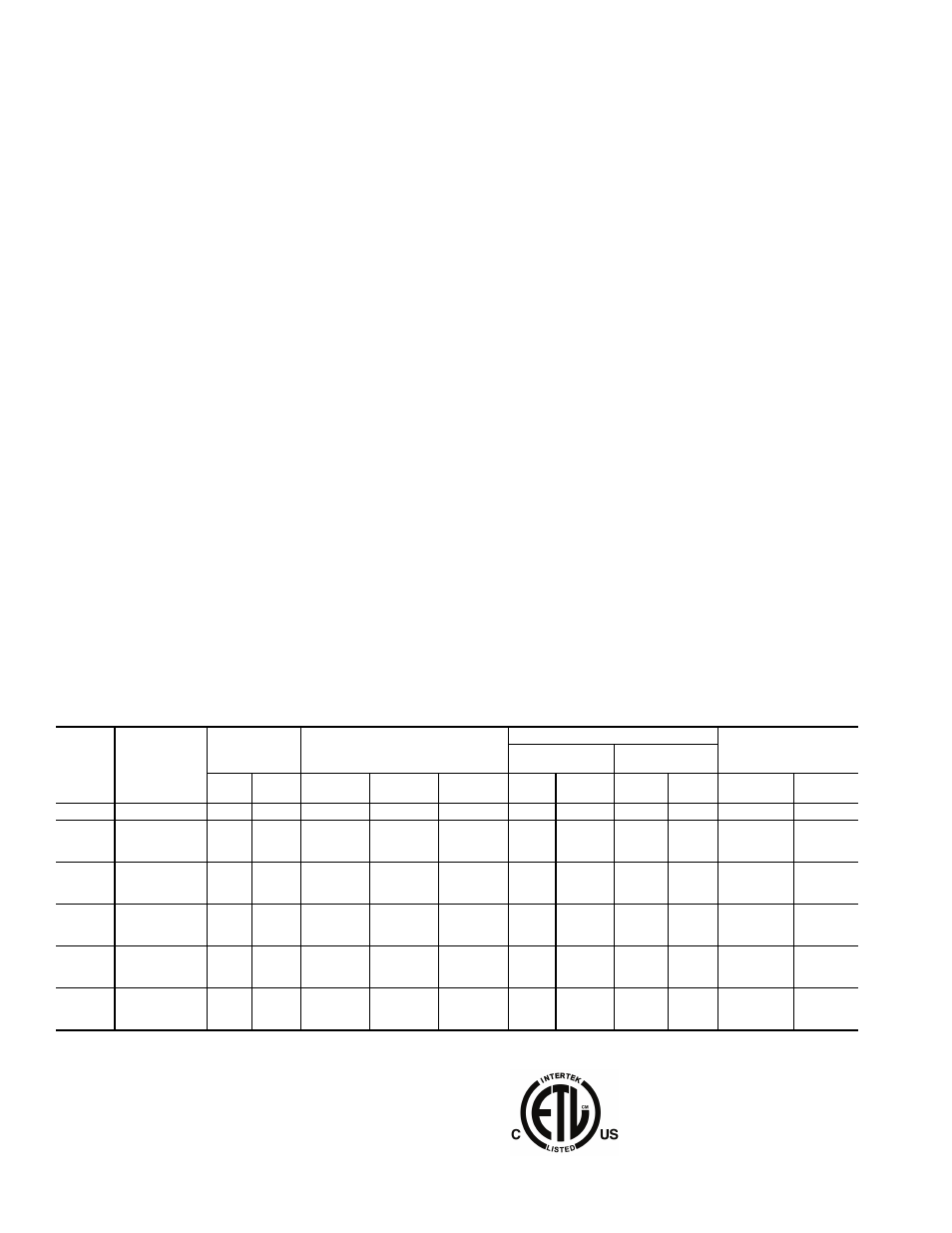

Table 2A — Electrical Data — Standard Evaporator Motor with Standard Condenser Motor

LEGEND

UNIT

50AH

V-PH

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

FAN MOTORS

POWER SUPPLY

Evaporator

(Standard)

Condenser

(Standard)

Min

Max

QTY

RLA

LRA

Hp

FLA

Hp

FLA

Min Ckt

Amps

MOCP

Amps

024

208/230-1

187

254

1

13.5

58.0

1

/

4

1.25

1

/

3

1.7

19.8

35

036

208/230-1

187

254

1

16.7

79.0

1

/

3

1.7

1

/

3

1.7

24.3

40

208/230-3

187

254

10.4

73.0

1

/

3

1.3

1

/

3

1.3

15.6

25

460-3

414

508

5.8

38.0

1

/

3

0.7

1

/

3

0.7

8.6

15

048

208/230-1

187

254

1

19.9

109.0

1

/

3

1.7

1

/

3

1.7

28.3

50

208/230-3

187

254

13.6

83.1

1

/

3

1.3

1

/

3

1.3

19.6

35

460-3

414

508

6.1

41.0

1

/

3

0.7

1

/

3

0.7

8.9

15

060

208/230-1

187

254

1

26.4

134

1

/

3

1.7

1

/

3

1.7

36.4

65

208/230-3

187

254

16.0

110.0

1

/

3

1.3

1

/

3

1.3

22.6

40

460-3

414

508

7.8

52.0

1

/

3

0.7

1

/

3

0.7

11.1

20

072*

208/230-1

187

254

2

16.7

79.0

1

/

2

2.5

1

4.2

44.3

60

208/230-3

187

254

10.4

73.0

1

/

2

1.8

1

3.2

28.4

40

460-3

414

508

5.8

38.0

1

/

2

0.9

1

1.6

15.6

20

096*

208/230-1

187

254

2

19.9

109.0

3

/

4

3.2

1

1

/

2

6.5

54.5

75

208/230-3

187

254

13.6

83.1

3

/

4

2.4

1

1

/

2

4.8

37.8

50

460-3

414

508

6.1

41.0

3

/

4

1.2

1

1

/

2

2.4

17.3

25

HACR — Heating, Air Conditioning, and Refrigeration

Hp

— Horsepower

FLA

— Full Load Amps

LRA

— Locked Rotor Amps

MOCP — Maximum Overcurrent Protection (HACR breaker)

RLA

— Rated Load Amps

*Unit has two compressors.