Start-up unit preparation, Compressor mounting, Internal wiring – Carrier ROOMTOP 50AH024-096 User Manual

Page 17: Refrigerant service valves, Compressor rotation, Cooling, Service filters, Condenser coil, Evaporator coil, Condensate drain

17

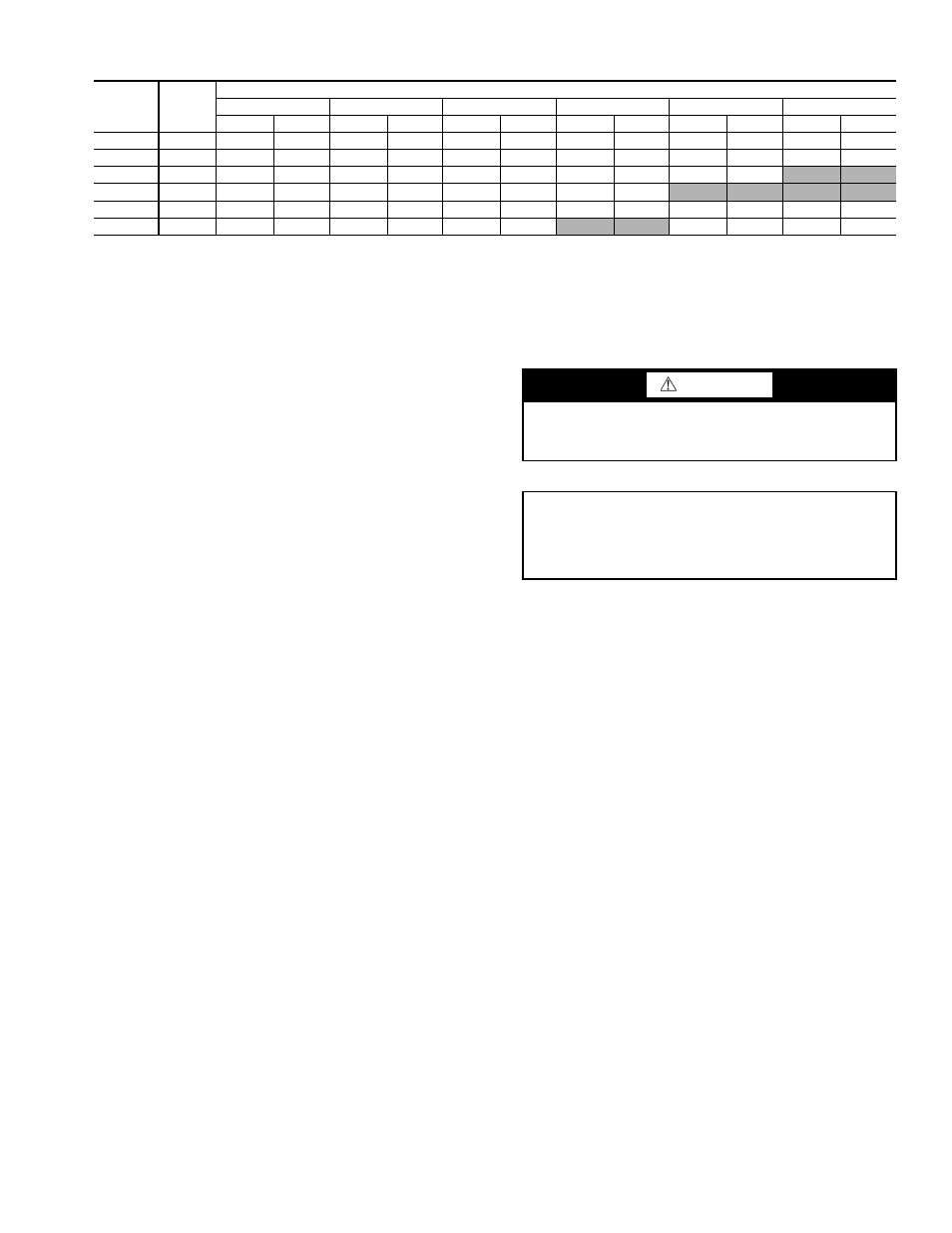

Table 4 — Condenser-Fan Performance

LEGEND

NOTES:

1. Refer to Table 1 for condenser fan motor and drive information.

2. Upgrade 1 Static Motor is required for boldface values.

3. Upgrade 2 Static Motor is required for shaded values.

START-UP

Unit Preparation —

Make sure unit has been installed in

accordance with installation instructions and applicable codes.

Compressor Mounting —

Compressors are internally

mounted on rubber-in-shear (RIS) isolators. Do not loosen or

remove compressor holddown bolts.

Internal Wiring —

Check all electrical connections in

unit control boxes and tighten as required.

Refrigerant Service Valves —

Each unit system has

2 Schrader-type service ports, one on the suction line and one

on the compressor discharge line. Be sure that caps on the ports

are tight.

Compressor Rotation —

On 50AH036-096, 3-phase

units, it is important to be certain compressor is rotating in the

proper direction. To determine whether or not compressor is

rotating in the proper direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pres-

sure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the condenser and evaporator fans may also be

rotating in the wrong direction.

2. Turn off power to the unit and tag disconnect.

3. Reverse any two of the unit power leads.

4. Reapply power to the unit; remove tag.

5. Verify correct refrigerant pressures.

The suction and discharge pressure levels should move to

their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direc-

tion, the unit will sound louder than normal and will not

provide cooling.

Cooling —

To start unit, turn on main power supply. Set

system selector switch at COOL position and fan switch at

AUTO. position. Adjust thermostat to a setting below room

temperature. Compressor, condenser and evaporator motors

start on closure of contactors.

TO SHUT OFF UNIT — Set system selector switch at OFF

position or reset thermostat at a position above room

temperature.

SERVICE

Filters —

Filters are disposable and should be inspected and

replaced at regular intervals monthly or as conditions require.

They are located in front of the evaporator coil and may be re-

moved by sliding them horizontally out to edge of unit. See

Fig. 2-5. No tools are required for installation or removal of

filters.

Condenser Coil —

The condenser coil is accessible

through the side access panel on condenser section, or through

side access panel on condenser section. Use a stiff brush when

cleaning coil. Be careful not to bend aluminum fins.

Evaporator Coil —

The evaporator coil is accessible for

cleaning through the side access panel on evaporator section.

When necessary, wash coil with a commercial cleaner (Oakite

164) or dishwasher detergent using a pressurized spray canis-

ter. Flush coil from return-air duct side and take care not to get

water in ductwork or unit insulation.

Condensate Drain —

Clean and empty drain pan at

least once a year to prevent sludge build-up.

Lubrication —

Lubrication of the condenser and evapora-

tor motors is not necessary since both are equipped with

permanently lubricated bearings. Do not oil.

Unit Condenser Motor —

All 50AH units contain

belt-driven adjustable-pulley fan systems. The unit fan motors

are shipped with adjustable pulley at 4 turns open.

Blower Wheel Servicing —

In-space servicing is rec-

ommended for the evaporator and condenser blowers. Both are

removed by loosening and removing the 2 screws (sizes 024-

060) or 4 screws (sizes 072 and 096) that hold them in place. In

both cases, the entire assembly is then moved outside of the

base unit. Once outside, the blower wheel and condenser shaft

bearings and/or evaporator motor can be serviced.

UNIT

SIZE

50AH

CFM

EXTERNAL STATIC PRESSURE (in. wg)

0.0

0.1

0.2

0.3

0.4

0.5

Rpm

Bhp

Rpm

Bhp

Rpm

Bhp

Rpm

Bhp

Rpm

Bhp

Rpm

Bhp

024

1700

247

0.07

255

0.07

262

0.08

269

0.08

277

0.08

284

0.09

036

2000

276

0.11

282

0.11

289

0.12

295

0.12

301

0.12

307

0.13

048

2500

251

0.17

305

0.18

357

0.22

408

0.27

456

0.32

501

0.37

060

3000

287

0.22

334

0.28

378

0.33

421

0.38

464

0.43

505

0.49

072

5200

367

0.68

438

0.89

464

0.98

490

1.07

516

1.16

542

1.25

096

6400

448

1.26

524

1.59

546

1.70

568

1.81

—

—

—

—

Bhp

— Brake Horsepower

WARNING

Disconnect all power to the unit before performing mainte-

nance or service. Electrical shock and personal injury could

result.

IMPORTANT: If repairs to refrigerant cycle compo-

nents (e.g., compressor, filter drier, etc.) are required,

recover all refrigerant from the system by using both

high and low-pressure ports. Then remove base unit

from the space.