Basic installation instructions, Ames 2, Notice – Ames Fire & Waterworks 5000CIV Cast Iron Reduced Pressure Detector Assemblies User Manual

Page 2

2

Basic Installation Instructions

Figure 2

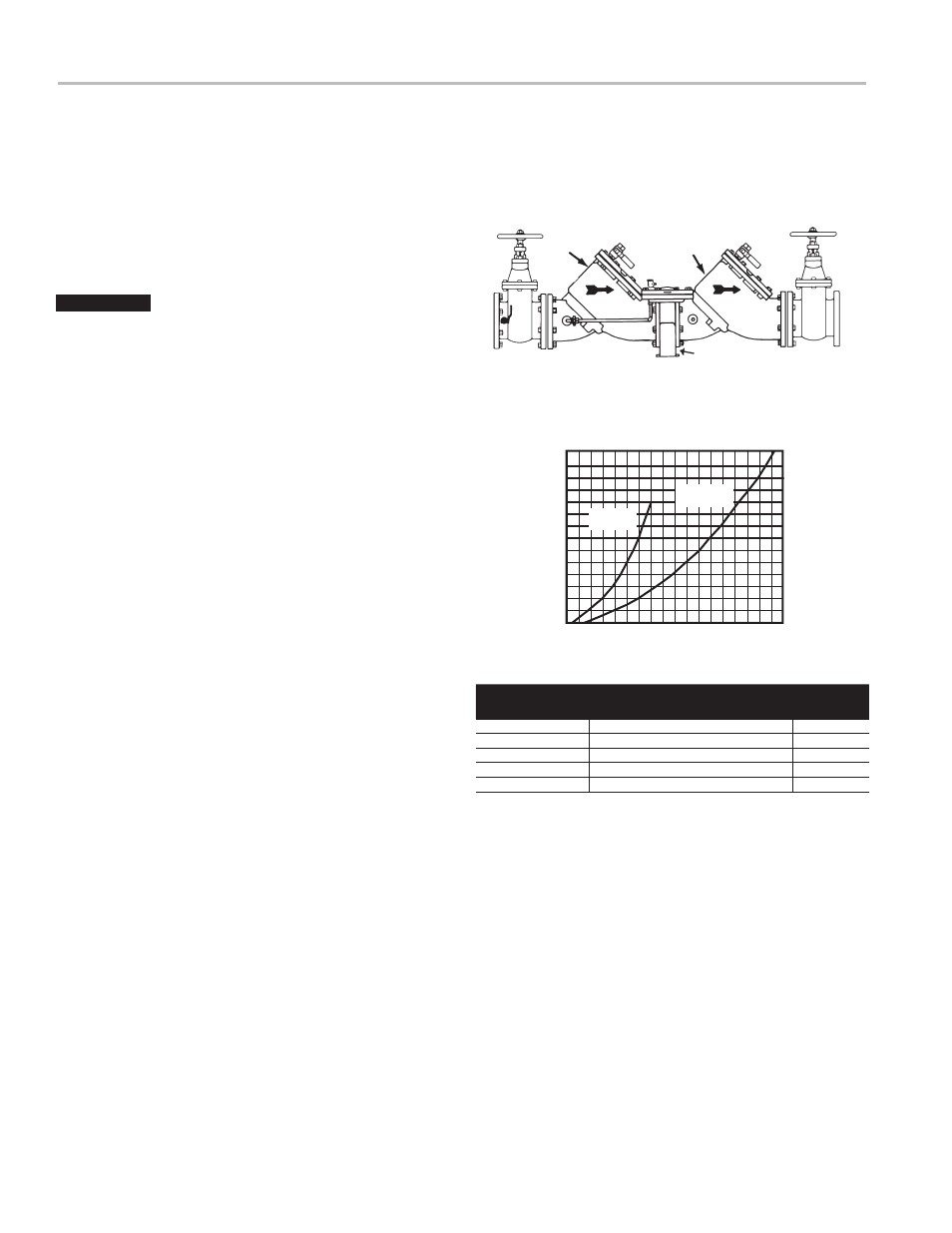

ValVE sIzE

TypICal FlOw RaTEs

as sIzEd By FlOOR dRaIn ManuFaCTuRERs

dRaIn sIzE

in.

mm**

in.

2

1

⁄

2

65

55 gpm

2

3

80

112 gpm

3

4

100

170 gpm

4

6, 8, 10

150-250

350 gpm

5

Figure 1

Model 5000CIV

Relief Valve Dis charge Rates

zO

nE

pRE

ssu

RE (

ps

IG)

FlOw RaTE (GpM)

2

1

⁄

2

" – 3"

(65-80mm)**

4" – 10"

(100-250mm)**

175

150

125

100

75

50

25

0

0 100 200 300 400 500 600 700 800 900

Relief Valve

First

Check

second

Check

second

shutoff

Valve

Inlet

shutoff

Valve

2

1

⁄

2

" – 10" (65-250mm)**

Ames 2

1

/

2

" – 10" (65-250mm)** 5000CIV

High Capacity Relief Series: Location and

Installation Considerations

6. The relief valve module on 2

1

⁄

2

" – 10" 5000CIV Series assemblies

may be turned to discharge to the opposite side. To do so,

unbolt the relief valve and turn the relief valve discharge port to

the opposite side. Mount the high pressure hose on the op po site

side. This should be done by a licensed journeyman tradesper-

son, who is rec og nized by the authority having jurisdiction and

only when space is critical for testing or repair.

NOTICE

7.

ASSEMBLY: If the backflow preventer is disassembled during

installation, it MUST be reassembled in its proper order. The gate

valve with the test cock is to be mounted on the inlet side of the

backflow preventer. The test cock must be on the inlet side of

the wedge. Please see above. Failure to reassemble correctly

will result in possible water damage due to excessive discharge

from the relief port/vent and possible malfunction of the backflow

preventer.

8. Installation procedures must comply with all state and local codes

and must be completed by a licensed journeyman tradesperson

who is recognized by the authority having ju ris dic tion.

9. Prior to installation, thoroughly flush all pipe lines to remove any

foreign matter.

10. START UP at Initial Installation and After Servicing: The down-

stream shutoff should be closed. Slowly open upstream shutoff

and allow the backflow preventer to fill slowly. Bleed air at each

test cock. When backflow preventer is filled, slowly open the

down stream shutoff and fill the water supply system. This is nec-

essary to avoid dislodging O-rings or causing damage to internal

com po nents.

11.

TEST: The Series 5000CIV backflow preventer may be tested by

a certified tester at the time of installation in order to ascertain

that the assembly is in full working order and may be relied upon

to protect the safe drinking water as per applicable standard.

** Metric Dimensions are nominal pipe diameter. This product is

produced with ASME/ANSI flanged end connections.