Testing — double check valve assemblies, Test check valve no. 1, Test check valve no. 2 – Ames Fire & Waterworks ATG-1 Backflow Preventer Test Kit User Manual

Page 4: Test for leaky no. 2 shutoff

Test Check Valve No. 1

Step 1: Ensure shutoff #1 is open, shutoff #2 is closed.

Step 2: Connect high side hose to test cock #3, low side to test cock #2

and open both test cock #2 and test cock #3.

Step 3: Open valve C, then open A to bleed air from the high side. Close

valve A, then open B to bleed low side. Close valve B.

Step 4: Connect vent hose loosely to test cock #1. Open valve A to vent

air from vent hose. Tighten vent hose at test cock #1, open test

cock #1.

Step 5: Close shutoff #1. Slowly loosen hose at test cock #2 until dif-

ferential gauge rises to 2psi and retighten hose. If the differential

reading does not decrease, record check valves as “tight”.

Test Check Valve No. 2

Step 1: Move the high side hose to test cock #4, low side to test cock

#3 and open both test cock #3 and test cock #4. Remove vent

hose from test cock #1, open shutoff #1.

Step 2: Open valve C, then open valve A to bleed air from the high

side. Close valve A, then open valve B to bleed low side. Close

valve B.

Step 3: Connect vent hose loosely to test cock #1. Open valve A to

vent air from the vent hose. Tighten vent hose at test cock #1,

open test cock #1.

Step 4: Close shutoff #1, then slowly loosen hose at test cock #3

until differential gauge rises to 2psi and retighten hose. If the

differential reading does not decrease, record check as tight.

Remove all hoses and restore valve to original working condition.

Note: The assembly will fail both the first and second check valve

tests above, if shutoff #2 leaks excessively. To test for a leaky #2

shutoff, use the following procedure.

Test for Leaky No. 2 Shutoff

Step 1: Connect the high side to test cock #1, low side to test cock #4.

Open test cock #1 and test cock #4. Close shutoffs #1 and #2.

Step 2: Close valve C. Open valve A, then open valve B

1

⁄

2

turn, loosen

hose at test cock #4 to remove air. Retighten hose.

Step 3: If the differential gauge rises above 0, there is excessive

leakage at shutoff #2 and it must be replaced to test the

assembly.

Note: Product information is subject to change without notice and

supersedes all previous publications.

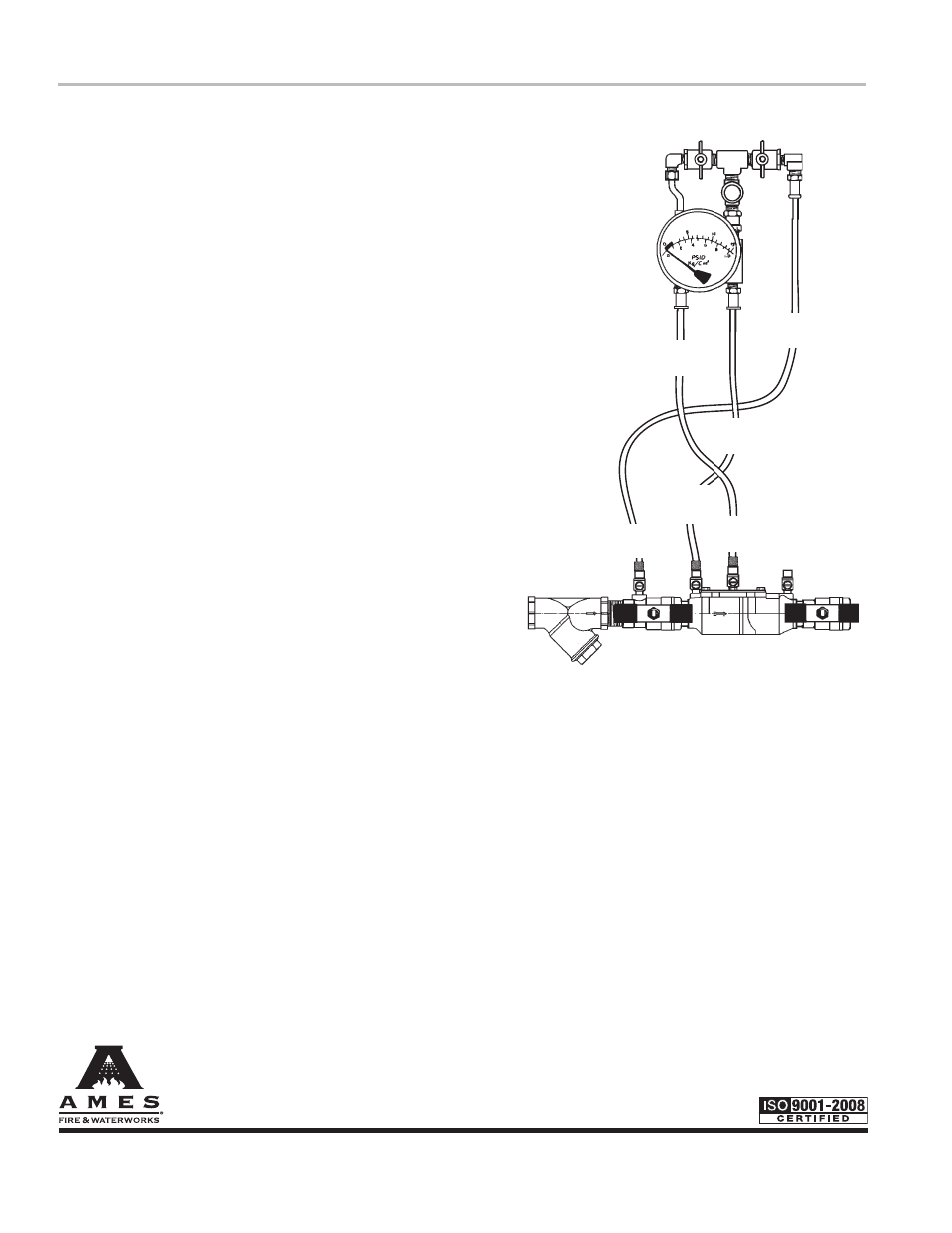

Testing — Double Check Valve Assemblies

Ball Type Test Valves

(A)

(C)

(B)

Needle

Valve

High Hose

(Yellow)

Low Hose

(White or Red)

Vent Hose

(Blue)

Test Cock

No. 1

Test Cock

No. 2

2000B shown

Test Cock

No. 3

Test Cock

No. 4

IS-A-ATG-1 0904

EDP# 1915327

© 2011 Ames Fire & Waterworks

www.amesfirewater.com

A Watts Water Technologies Company

USA: Backflow- Sacramento, CA • Tel: (916) 928-0123 • Fax: (916) 928-9333

Control Valves- Houston, TX • Tel: (713) 943-0688 • Fax: (713) 944-9445

Canada: Burlington, ON • Tel: (905) 332-4090 • Fax: (905) 332-7068