Installation, Materials, Installation practices – Ames Fire & Waterworks IBR In-Building Risers User Manual

Page 3: Field test procedures, Constrained piping, Free piping

3

Installation

Materials

Because the In-Building Riser is buried, the material of

construction has been chosen as Type 304L Stainless Steel.

This material is generally recognized as a corrosion resistant

material which is superior to Cast, Ductile Iron, or Coated

Steel pipe for corrosion resistance, and which is superior to

engineered plastics for strength and longevity. In general,

the stainless steel is the cathode in joints of dissimilar metal,

so that any corrosion which may occur will not affect the

stainless steel. In addition, an extra protection is provided

in that there is no actual metal to metal contact at either

joint due to the CIPS bell connection design and the groove

coupler design.

Installation Practices

Good installation practice for all types of buried pipe often

calls for wrapping of the pipe to decrease corrosion due to

soil conductivity. Although stainless steel is less susceptible

to corrosion, local codes and general practices should still

be followed.

Field Test Procedures

Normal field test procedures call for a hydrostatic pressure

test of the system prior to final acceptance. Often, segments

of the system will be tested individually prior to the complete

system test. In order to hydrostatically test the In-Building

Riser as installed, two methods are recommended.

1. Constrained Piping

If the piping installation is essentially complete, the piping

restraints may adequately take the thrust loads generated by

having a blind end on the pipe system. In these cases, no

special actions to restrain thrust or side loads are required,

and the fitting installed in the system may be adequate for

hydrostatic testing.

2. Free Piping

If just the riser or riser/main connection is to be tested, then

the thrust loads from the blind end cap on the riser may need

to be restrained. The riser design has been tested in the

unrestrained state using a rigid coupler and end cap grooved

fitting. Flange adapters, expansion fittings, or other styles

of end connectors may result in excessive end thrust which

may cause a leak or fitting malfunction. In addition, couplings

which are adequately rated for high pressure testing should

be used if thrust restraints are not feasible.

Note: It is important that all air is bled from the system before pressurizing

any component.

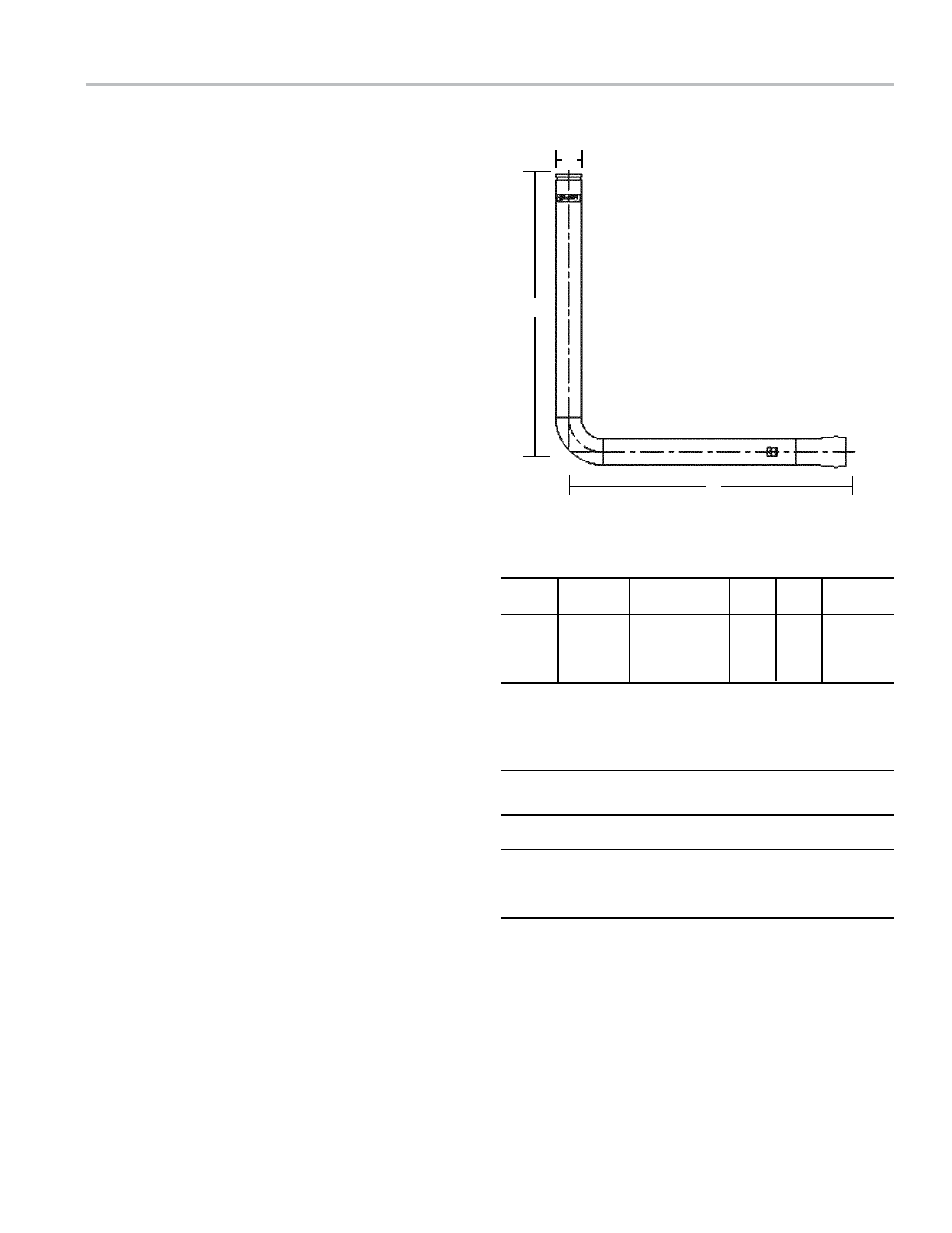

A

B

C

Dimensions/Weights

Size Ordering

A

B C Weight

in. mm

Code

inch ft.

ft.

lbs.

4 100

0690970

4

1

⁄

2

OD

6

6

71

6 150

0690969

6

5

⁄

8

OD

6

6

98

8 200

0690968

8

5

⁄

8

OD

6

6

129

10 250

0690971

10

3

⁄

4

OD

6

6

202

End Connections

Bell End: Mates with Ductile Iron Pipe and AWWA C900 Pipe (PVC Pipe with Cast Iron

Pipe Equivalent OD's)

Size

Sealing Gasket (CIPS – C900)

in. mm

Mating Pipe OD

Spare Part Ordering code

4 100

4.80

7014421

6 150

6.90

7014422

8 200

9.05

7014423

10 250

11.10

7014424

Utilizes Gasket conforming to UL 157 with “Lock in” gasket configuration.