Basic installation instructions – Ames Fire & Waterworks IBR In-Building Risers User Manual

Page 2

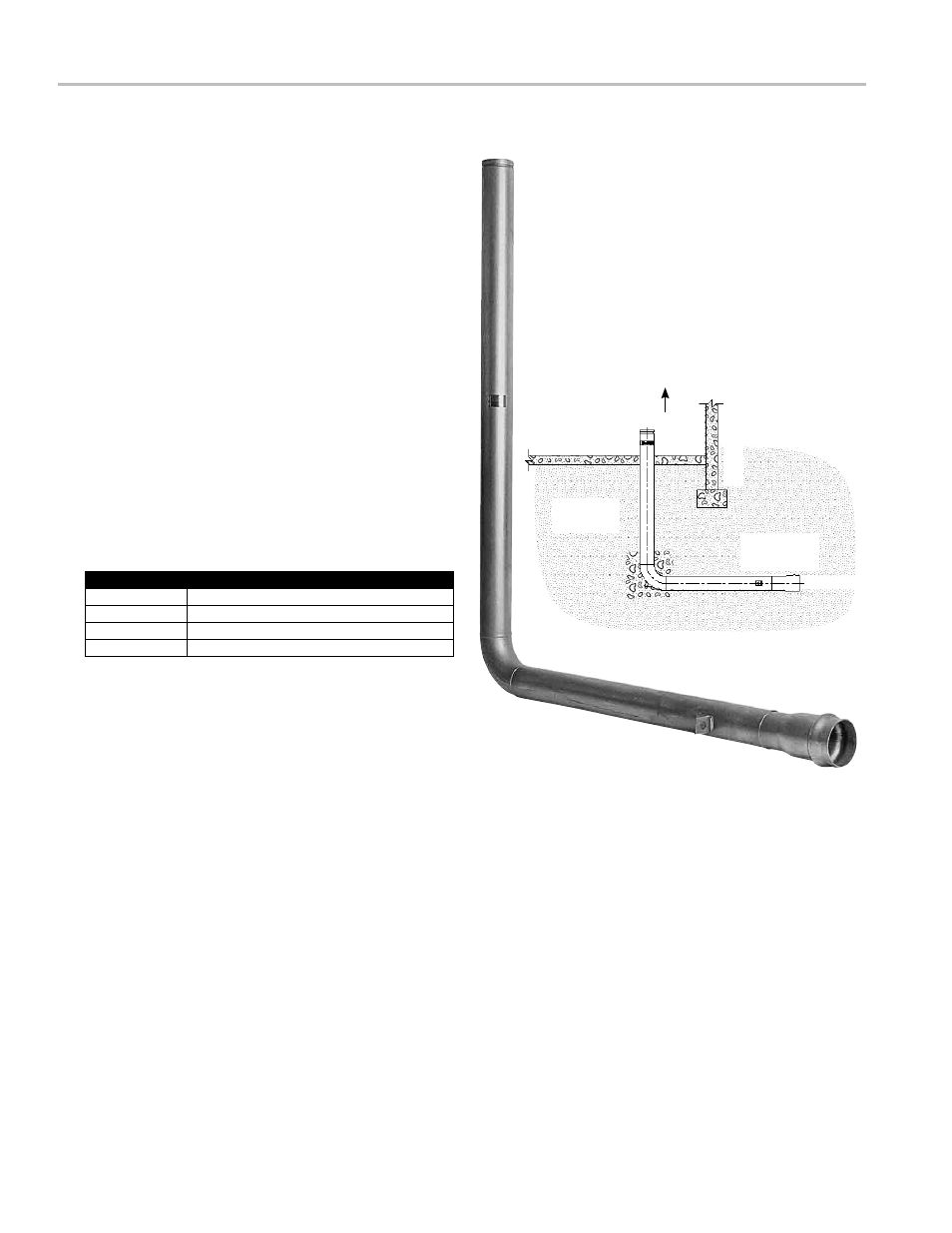

Ames Company In-Building Risers are designed for easy

installation in standard configurations as outlined using

standard construction method.

The floor penetration detail of the In-Building Riser shall be

restrained per direction outlined by site plans. Consult Uni-

Bell handbook of PVC pipe if instructions are not provided.

The below ground connection is a standard AWWA C900

gasketed coupler (either ductile iron or PVC). Installation in

accordance with the following information (from Uni-Bell

handbook).

1. Clean out inside of coupler making certain the beveled

spigot end and the gasket groove are free of dirt.

2. Apply lubricant to beveled spigot (male).

3. Insert gasket into coupling groove and seat firmly.

4. Push lubricated end past gasket into the bell housing. (Ames

in-building risers are equipped with the lugs placed 180°

apart on either side of the unit which can be used to “pull”

the pipe into the bell using a “come a-long” type equipment.

Also, the “bar and block method described in the Uni-Bell

handbook can also be used for installation).

5. The maximum allowable pipe deflection angle between the

IBR and underground pipe is as follows:

The above ground connection is an AWWA specification C606

groove. All underwriters Laboratory approved groove couplers

made to fit the AWWA C606 grooves can be used to join the

connection to the in-building supply line.

1. Check gasket and lubricate it using groove coupler manu-

facturer's recommended lubricant or approved equal.

2. Install gasket. Place gasket over pipe end being sure gasket

lip does not overhang pipe end.

3. Align and bring two pipe ends together and slide gasket into

position centered between grooves or each pipe (no portion

of the gasket should extend into the groove of either pipe.)

4. Apply housings. Place housings over gasket, being sure

the housing keys engage into the grooves of the pipe. (No

portion of the gasket should extend into the groove of either

pipe.)

5. If restraint fitting is being used tighten nuts: Tighten nuts

alternately and equally until housing bolt pads are firmly

together metal to metal: Uneven tightening will cause gasket

to pinch.

Important: Inquire with governing authorities for local

installation requirements.

attn. Installer: after Installation, please leave this instruction

sheet for occupant's information.

2

Basic Installation Instructions

Grooved End

Flow

Building Perimeter

Building

Floor

CIPS Cou-

plings

Flow

TR Size

Maximum Deflection

4"

1°

6"

1°

8"

1°

10"

1°