Step 2 — blower motor and wheel maintenance, 58mc b – Carrier 58MCB User Manual

Page 4

4

Table 1 – Furnace Air Filter Table

FURNACE CASING WIDTH

IN (MM)

FILTER QUANTITY AND SIZE *

FILTER TYPE*

SIDE RETURN

*

IN (MM)

BOTTOM RETURN*

IN (MM)

17---1/2 (445)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

3/4” (19 mm) thick washable

21 (533 )

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 20 x 25 x 3/4

(508 x 635 x 19)

3/4” (19 mm) thick washable

24---1/2 (610)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 24 x 25 x 3/4

(610 x 635 x 19)

3/4” (19 mm) thick washable

Table 2 – Air Filter Located in Filter Cabinet

FILTER CABINET HEIGHT --- IN (MM)

FILTER SIZE --- IN (MM)

FILTER TYPE

16 (406)

(1) 16 x 25 x 3/4*

(406 x 635 x 19) or

(1) 16 x 25 x 4---5/16

(406 x 635 x 110)

washable

20 (508)

(1) 20 x 25 x 3/4*

(508 x 635 x 19) or

(1) 20 x 25 x 4---5/16

(508 x 635 x 110)

washable

24 (610)

(1) 24 x 25 x 3/4*or

(610 x 635 x 19) or

(1) 24 x 25 x 4---5/16

(610 x 635 x 110)

washable

* Filters with a side return--air may have a different filter size. Measure the filter to obtain the correct size.

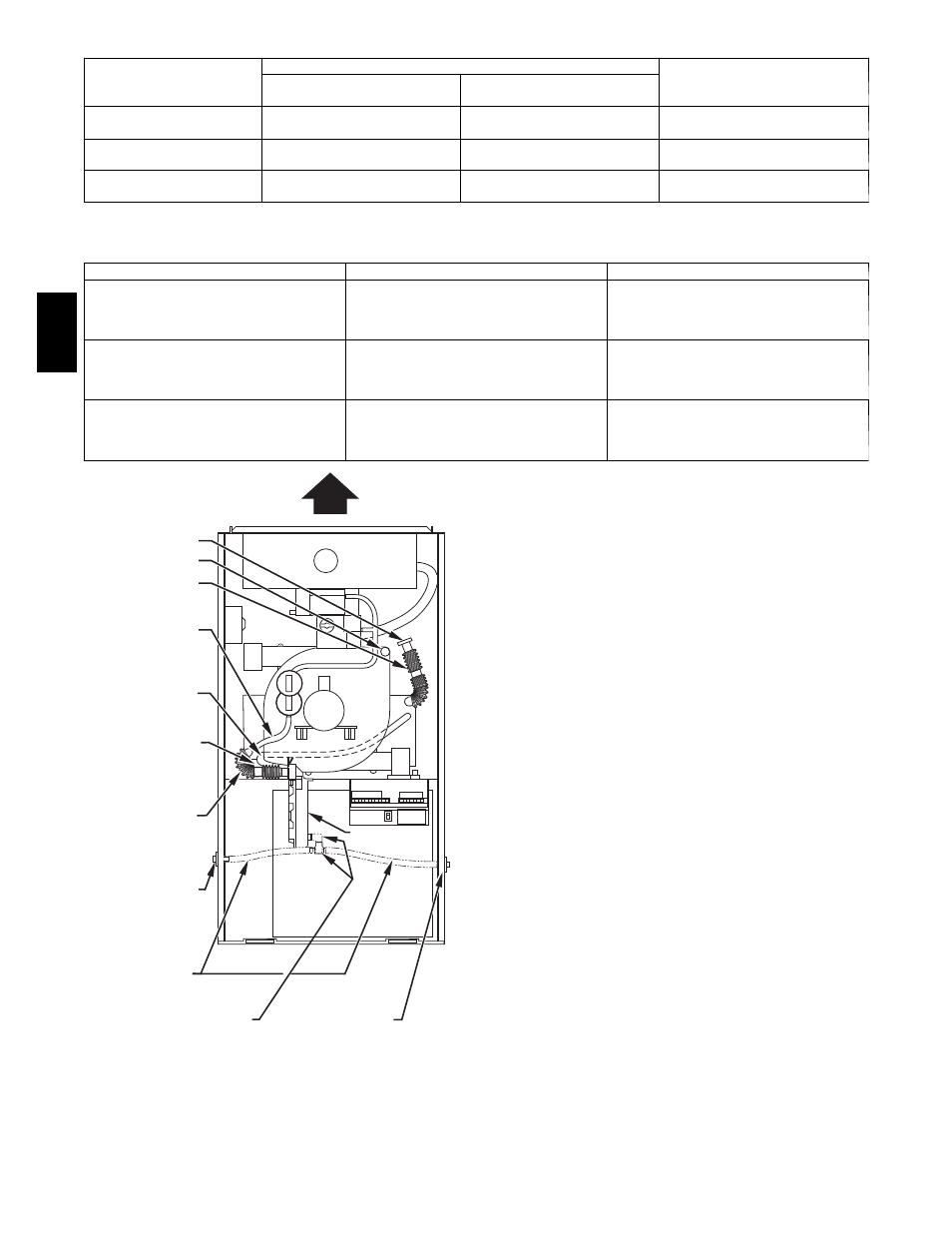

COLLECTOR BOX

TUBE (PINK)

COLLECTOR BOX

TUBE (GREEN)

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (BEHIND

COLLECTOR BOX

DRAIN TUBE)

COLLECTOR BOX

DRAIN TUBE (BLUE)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (LEFT

DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

FIELD-INSTALLED

FACTORY-SUPPLIED

1

⁄

2

-IN. CPVC STREET

ELBOWS (2) FOR

LEFT DRAIN OPTION

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (RIGHT

DRAIN OPTION)

CAP

COLLECTOR BOX

DRAIN TUBE (BLUE

& WHITE STRIPED)

PLUG

CONDENSATE

TRAP

A05110

Fig. 5 -- Factory--Shipped Upflow Tube Configuration

(Shown with Blower Access Panel Removed)

1. Turn off electrical supply to furnace.

2. Remove filter cabinet door.

3. Slide filter out of cabinet.

4. If equipped with permanent, washable filter, clean filter by

spraying cold tap water through filter in opposite direction

of airflow. Rinse filter and let dry. Oiling or coating of the

filter is not recommended.

5. If equipped with factory specified disposable media filter,

replace only with a factory specified media filter of the same

size.

6. Slide filter into cabinet.

7. Replace filter cabinet door.

8. Turn on electrical supply to furnace.

If filter is installed in furnace blower compartment:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

3. Release filter retainer wire. (See Fig. 3 or 4.)

NOTE: Filters shown in Fig. 3 and 4 can be in furnace blower

compartment or in filter cabinet, but not in both.

4. Slide filter out of furnace.

5. If furnaces are equipped with permanent, washable filter(s),

clean filter by spraying cold tap water through filter in op-

posite direction of airflow.

6. Rinse filter and let dry. Oiling or coating filter is not recom-

mended.

7. Slide filter into furnace.

8. Recapture filter retaining wire.

9. Replace blower access panel and main furnace door.

10. Turn on electrical supply to furnace.

Step 2 — Blower Motor and Wheel Maintenance

To ensure long life, economy, and high efficiency, clean

accumulated dirt and grease from blower wheel and motor

annually.

The inducer and blower motors are pre--lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician.

Clean blower motor and wheel as follows:

58MC

B