Cooper Instruments & Systems Series M4 Digital Force Gage User Manual

Page 9

CF 182

6

32-1117 1010

Refer to the following sections for details about setting up particular functions and parameters.

5 OPERATING MODES

Caution!

In any operating mode, if the capacity of the instrument has been exceeded by more than 110%, the

display will show “OVER” to indicate an overload. A continuous audible tone will be sounded until

the MENU key has been pressed or the load has been reduced to a safe level.

Three operating modes are possible with Series 4 gauges. To cycle between the modes, press MODE while

in the home screen.

5.1 Real time (RT)

The primary reading corresponds to the live measured reading.

5.2 Peak Compression (PC)

The primary reading corresponds to the peak compression reading observed. If the actual force decreases

from the peak value, the peak will still be retained in the primary reading area of the display.

Pressing ZERO will reset the value.

5.3 Peak Tension (PT)

Same as Peak Compression, but for tension readings.

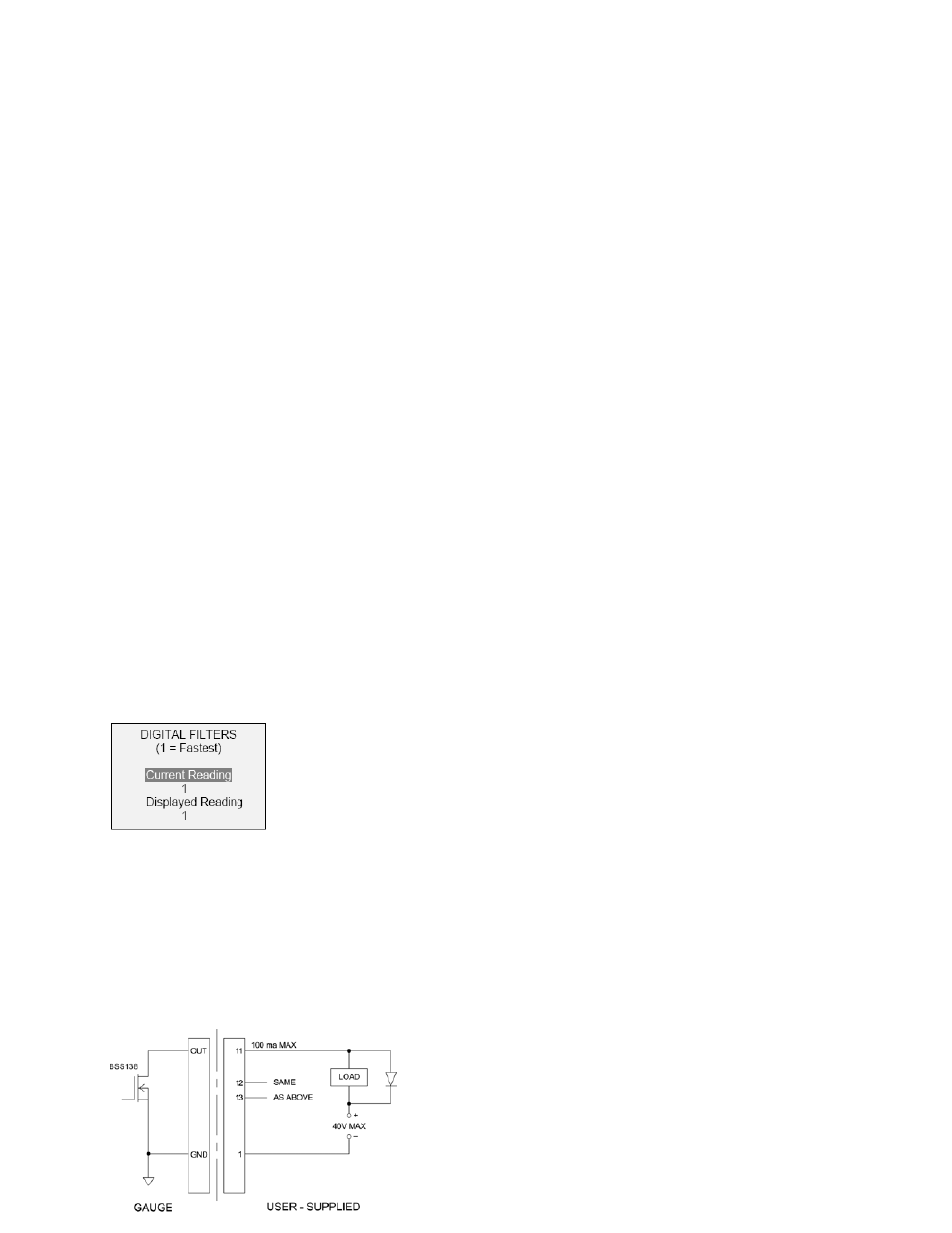

6 DIGITAL FILTERS

Digital filters are provided to help smooth out the readings in situations where there is mechanical

interference in the work area or test sample. These filters utilize the moving average technique in which

consecutive readings are pushed through a buffer and the displayed reading is the average of the buffer

contents. By varying the length of the buffer, a variable smoothing effect can be achieved. The selection of 1

will disable the filter since the average of a single value is the value itself.

To access digital filter settings, select Filters from the menu. The display will appear as follows:

8

Two filters are available:

Current Reading – Applies to the peak capture rate of the instrument.

Displayed Reading – Applies to the primary reading on the display.

Available settings: 1,2,4,8,16,32,64,128,256,512,1024. It is recommended to keep the current reading filter at

its lowest value for best performance, and the displayed reading filter at its highest value for best stability.

7 SET POINTS

7.1 General Information

Set points are useful for tolerance checking (pass/fail),

triggering an external device such as a motorized test stand,