Bio-Rad DCode™ Universal Mutation Detection System User Manual

Page 55

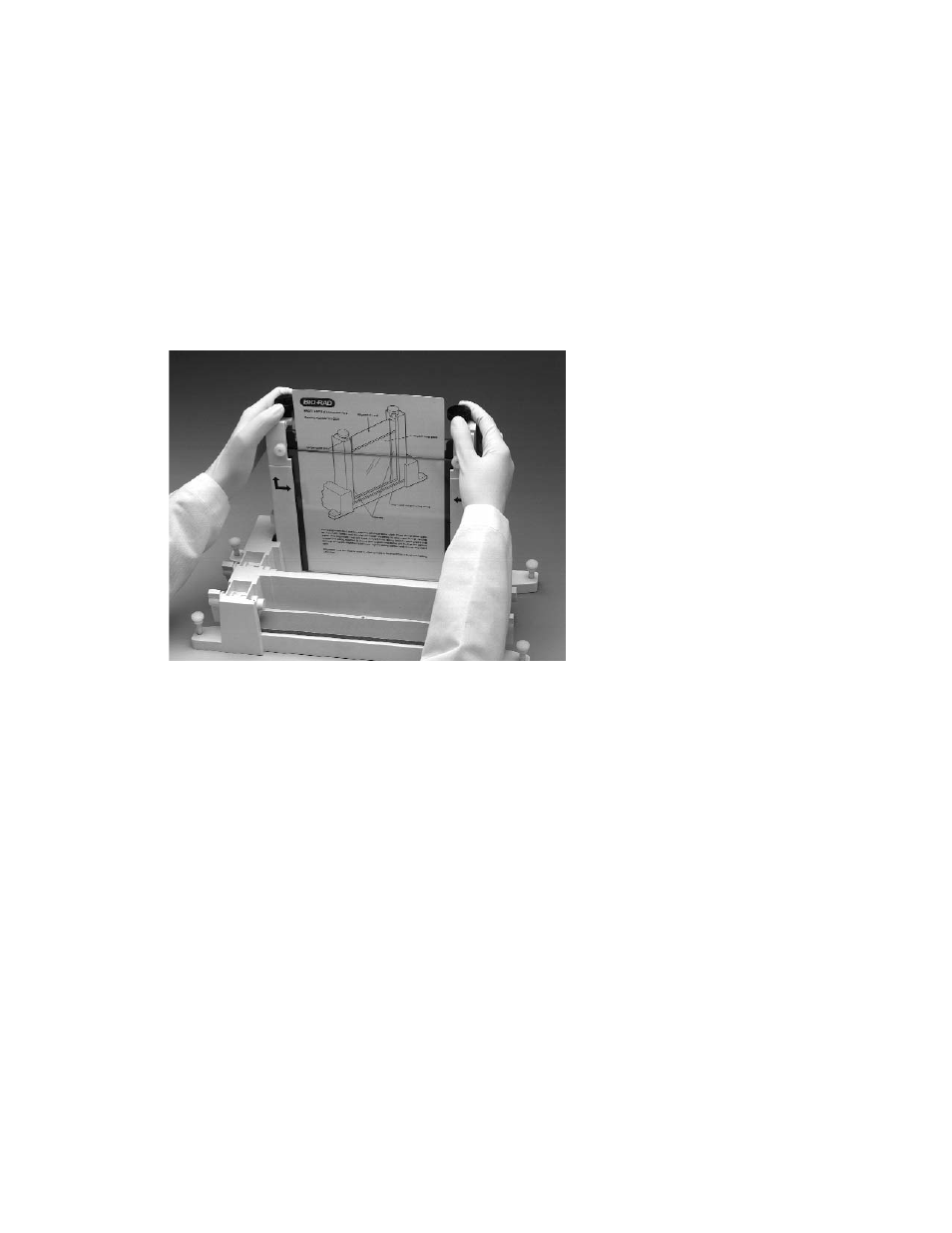

5. Place the sandwich assembly in the alignment slot (the slot without cams) of the casting

stand with the short glass plate forward (Figure 5.4). Loosen the sandwich clamps and

insert an alignment card to keep the spacers parallel to the clamps.

Note: Always use the alignment slot and alignment card to set the spacers in place. Failure

to use these can result in gel leakage when casting, as well as buffer leakage during the

run.

6. Align the plates and spacers by simultaneously pushing inward on both clamps at the locating

arrows while pushing down on the spacers with your thumbs. Tighten both clamps just enough

to hold the sandwich in place. Pushing inward on both clamps at the locating arrows will insure

that the spacers and glass plates are flush against the sides of the clamps (Figure 5.4).

Fig. 5.4. Aligning spacers in the sandwich assembly.

7. Remove the alignment card. Remove the sandwich assembly from the casting stand and

check that the plates and spacers are flush at the bottom. If they are not flush, realign the

sandwich and spacers for a good seal (Repeat steps 5–7).

8. When a good alignment and seal are obtained, tighten the clamp screws until it is finger-tight.

5.8 Casting Heteroduplex Analysis Gels

1. Place the gray sponge onto the front casting slot. The camshafts on the casting stand

should have the handles pointing up and pulled out. Place the sandwich assembly on the

sponge with the shorter plate facing forward. When the sandwich is placed correctly, press

down on the sandwich and turn the handles of the camshaft down so that the cams lock

the sandwich in place.

2. Into a 50 ml tube, add the required amounts of DEM solution (Section 5.2). Add a final

concentration of 0.09% (v/v) each of ammonium persulfate and TEMED solutions. Cap the

tube and mix.

3. Insert a comb in the gel sandwich and tilt it so that the teeth are at a slight angle. This will

prevent air from being trapped under the comb teeth when pouring the gel solution

(Figure 5.5).

51