Optimizing heat sealing – Bio-Rad Peelable Foil Heat Seal User Manual

Page 12

6

Chapter 2 — Using the PX1 PCR Plate Sealer

Optimizing Heat Sealing

Sealing optimization is a crucial step to ensure a

high-quality seal. Sealing a plate for too long or at

too high a temperature can result in oversealing and

potentially affect the quality of data in optical assays,

including qPCR. Undersealing a plate may permit

sample evaporation.

Tip: Optimize sealing conditions using an empty plate.

1. Seal an empty plate with the recommended

sealing parameters listed in Chapter 5.

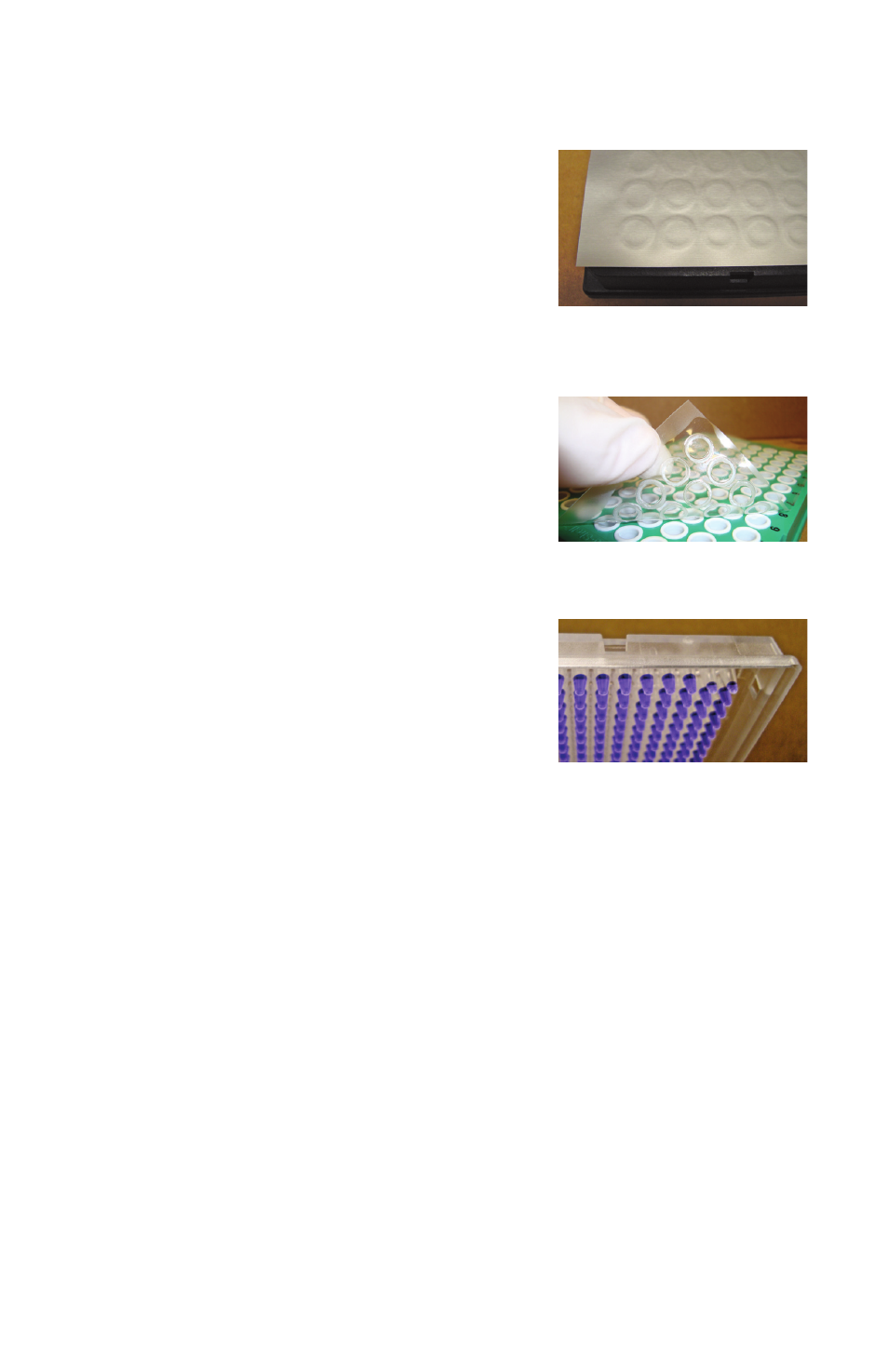

2. Carefully examine the entire seal and plate surface.

Look for even sealing around each individual well

and across the entire plate (Figure 9).

3. Make sure well rims are not significantly deformed.

Note: Minimizing well deformation is especially

important for qPCR assays. Significant well

deformation could affect optical readings.

4. If using a peelable seal, peel off the seal and

examine the adhesive patterns where the wells

contacted the seal. Look for uniform circular

imprints across the entire seal (Figure 10).

5. Optional: fill a sample plate with a colored liquid

such as 0.01% bromophenol blue solution.

Examine sample volumes to ensure pipetting

accuracy. Seal the plate. Thermal cycle the plate

and examine all wells for signs of evaporation

(Figure 11).

6. Save optimized sealing protocol so that it can

be easily accessed for future experiments. Refer

to Storing and Using Sealing Protocols section for

detailed instructions.

Fig. 10. Uniform and complete

circles demonstrate good sealing.

Fig. 9. Impressions should have

uniform width around individual

wells and across entire plate.

Fig. 11. Examine sample volumes

after cycling. In this demo,

corner wells were poorly sealed to

demonstrate sample evaporation.