Great Plains 1520P Operator Manual User Manual

Page 42

1510P and 1520P

118-732M

5/6/2010

40

Tighten that fitting. Repeat process until all

loosened fittings have been bled and tight-

ened.

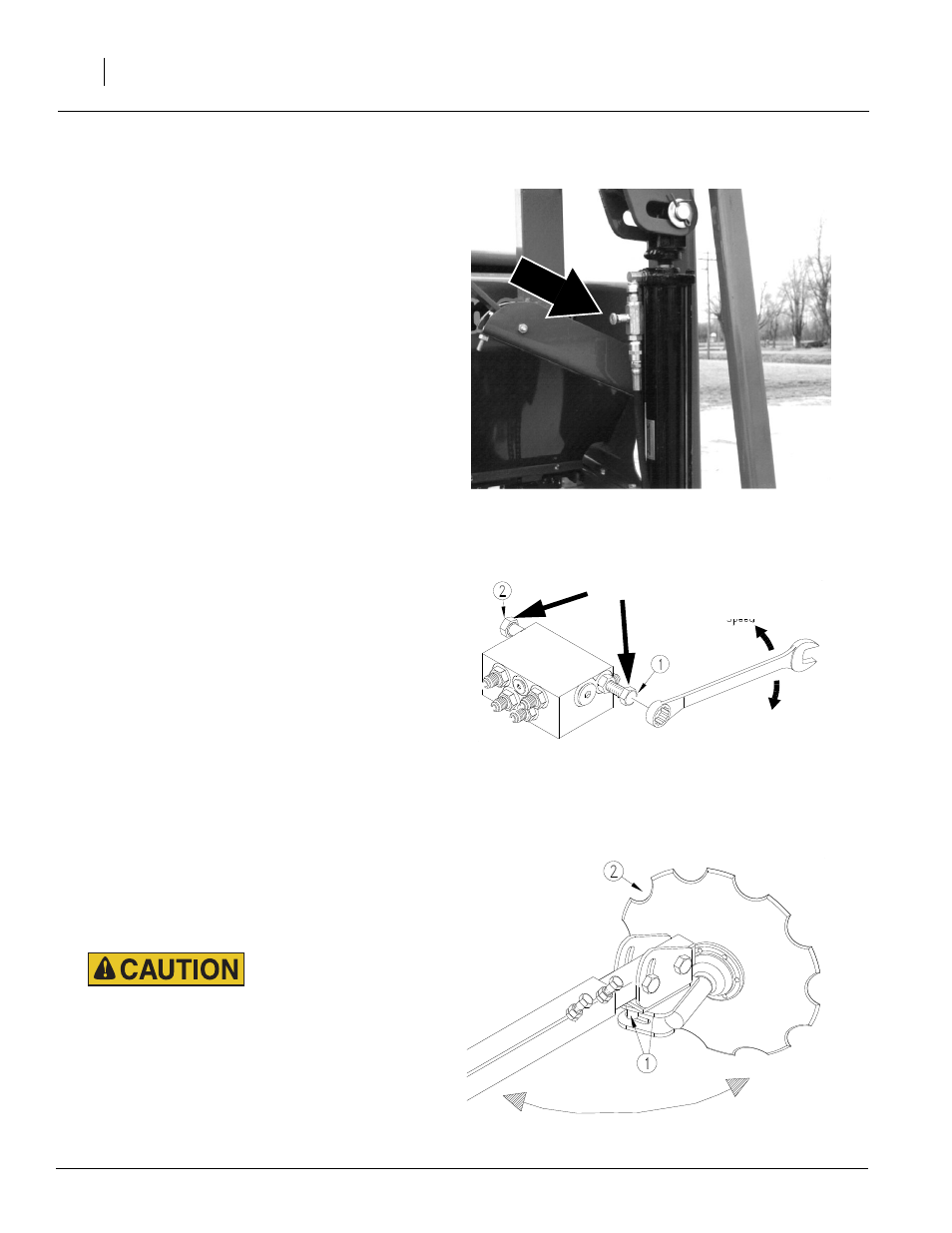

Folding Speed with Needle Valves

Refer to Figure 46

A needle valve controls the folding speed of mark-

ers that are plumbed separately. The needle valve

is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed,

adjust marker folding to a safe speed. Turn adjust-

ment knob clockwise to reduce folding speed or

counterclockwise to increase folding speed. Ex-

cessive folding speed could damage markers and

void the warranty.

Refer to Figure 47

Folding Speed with Sequence Valve

If markers are tied together with an optional se-

quence valve, adjust folding speed with hex

adjustment screws on the sequence-valve body.

There is one adjustment screw for raising speed

(1) and one for lowering speed (2). Identify adjust-

ment screws by markings stamped in valve body.

With tractor idling at a normal operating speed,

adjust marker folding to a safe speed. Turn adjust-

ment screws clockwise to decrease folding speed

and counterclockwise to increase folding speed.

Excessive folding speed could damage markers

and void the warranty.

After adjusting the folding speed, tighten jam nuts

on hex adjustment screws to hold settings.

Marker Disk Adjustment

Marker disks may be sharp. Use caution when making

adjustments in this area

Refer to Figure 48

Changing disk angle. If mark left by marker disk

is not clearly visible, adjust disk angle to make a

wider mark. Loosen two

1

⁄

2

inch bolts (1) holding

Figure 46

Needle Valve

17620

Figure 47

Speed Adjustment, Sequence Valve

14048

Hex adjustment

screws

Increase

speed

Decrease

speed

Figure 48

Disk Angle

17676