Frame height, Seeding rate – Great Plains 1520P Operator Manual User Manual

Page 32

1510P and 1520P

118-732M

5/6/2010

30

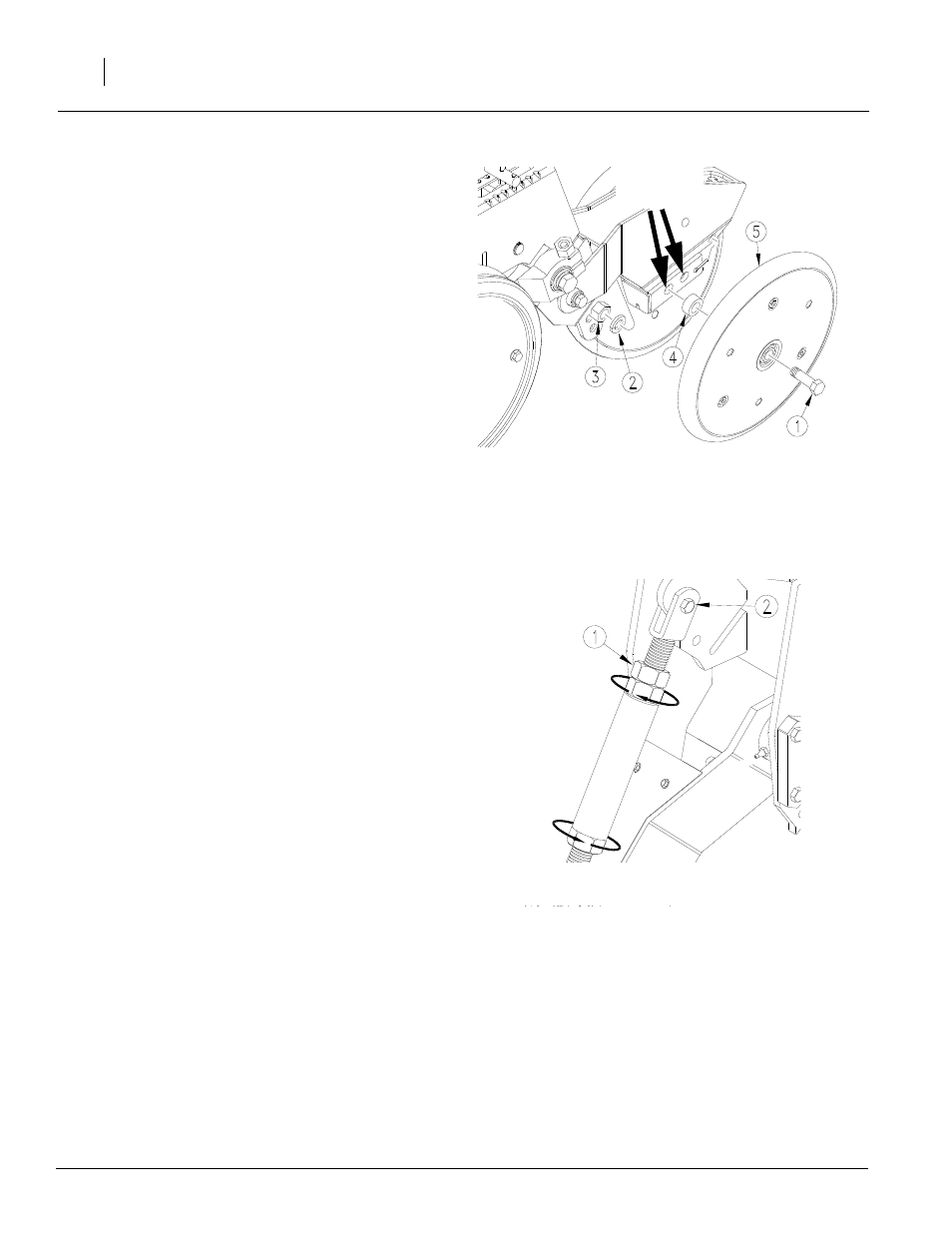

NOTE: The factory setting on the press wheel

is staggered to achieve optimum residue flow.

Refer to Figure 27

If you want to adjust press wheels from staggered

to even, remove 5/8 inch bolt (1), lock washer (2)

and nut (3). Reinstall spacer (4), press wheel (5)

and hardware to the other hole location.

Frame Height

Drill operating height directly affects the working

range of the drill openers. Initially adjust frame

height as explained under “Leveling Drill”, page

17. You can make further adjustments to compen-

sate for field conditions.

Refer to Figure 28

Make sure upper clevis (2) is in the upper mount

hole. Loosen jam nut (1) to lengthen or shorten

gauge-wheel turnbuckle.

• Lengthening turnbuckles raises drill and al-

lows less opener down float.

• Shortening turnbuckles lowers drill and al-

lows less opener up float.

Adjust both turnbuckles to the same length and

tighten jam nuts.

After adjusting gauge-wheel turnbuckles, be sure

to level the drill with top hitch link.

NOTE: Lowering the drill increases the risk of

opener damage on rocks or obstructions.

Seeding Rate

Adjusting the seeding rate requires the following:

1.

adjusting drive speed range sprockets,

2.

adjusting transmission sprockets,

3.

preparing seed meters,

4.

checking seeding rate.

Before setting the seeding rate, rotate the gauge

wheels. Check that seed meters, seed tubes and

drives are working properly and free from foreign

material.

Figure 27

Press Wheel Stagger

18410

Hole

locations

Figure 28

Gauge-Wheel Turnbuckle

12067