Install mounts & sensors, Install mounts, Install sensors – Great Plains 116-283A Installation Instructions User Manual

Page 6

6

Great Plains Manufacturing, Inc.

LOUP 2/3 CHANNEL SHAFT MONITOR

116-284M

2013-08-27

Install Mounts & Sensors

Install Mounts

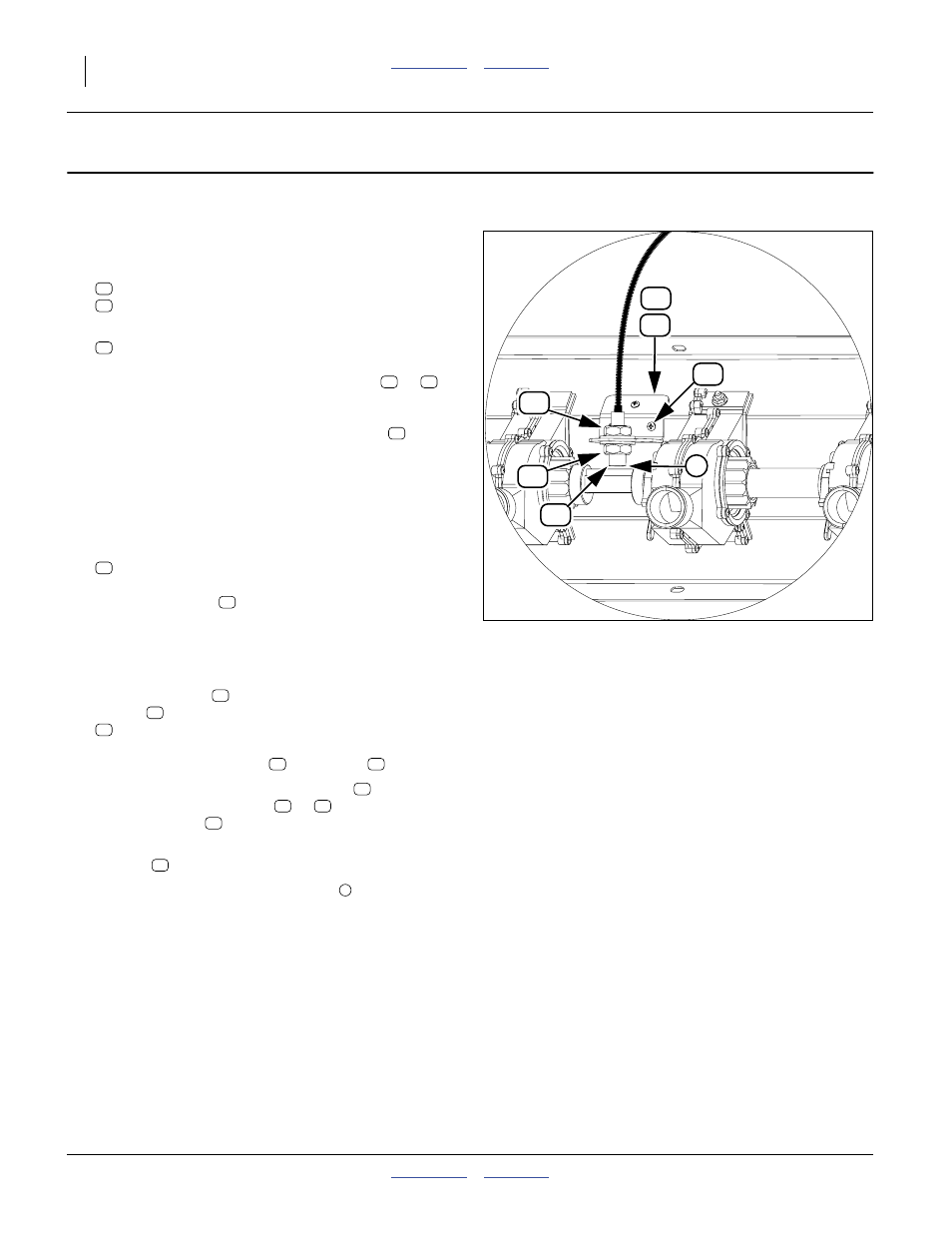

Refer to Figure 9 (which is a bottom view - drill front is at the

top of the illustration)

30. Depending on feeder cup size, select three of:

(“Large”)

116-020D SMALL CUP SENSOR MOUNT

31. Select three new:

801-199C SCR SELF TAP #10 X 3/4

With the slotted-hole break of the mount (

down and to the rear, and the short break of the

mount up and to the front, secure the mount to the

seed box wall with the self-tapping screws

Note: Do not over-tighten the screws.

32. Repeat step 31 for each sensor position.

Install Sensors

33. Select one new:

253100 LOUP SHAFT SENSOR 2&3 CHANNEL

If two plastic nuts

are pre-installed, remove and

save one.

If the sensor may include a bracket not used in this

installation. Remove it.

34. If no plastic nuts

sensor

, select two new:

710425 NUT HEX JAM, PLASTIC M16 X 2

Thread one jam nut onto

35. Insert the flat faced end of the sensor

through the

slotted hole in the mount (

second jam nut

36. Check that the drive shaft is rotated so that the

magnet

face is parallel to the sensor face.

37. Adjust the jam nuts so that the gap

between the

sensor face and the magnet face is:

1

⁄

8

inch (3.2 mm)

Note: If the gap is too small, the edge of the magnet, or

the cable ties, may strike the sensor as the shaft

rotates. If the gap is too large, the sensor may fail

to detect shaft rotation.

38. Rotate the shaft to verify clearance. Set the seed

rate handle to 0 and check clearance again. Set the

seed rate handle to 100 and check clearance.

39. Tighten the jam nuts. Do not over-tighten.

40. Repeat step 33 through step 39 for each sensor

position.

Figure 9

Mount & Sensor Install

34210

8

24

8