Caution – Great Plains 3SF45 Operator Manual User Manual

Page 36

4/8/99

6-4

170-062M

PLANTING DEPTH ADJUSTMENTS

LEVELING THE DRILL

This is a general dimension and may vary with the spring

down-float you require for different soil conditions and

planting depths see “

Press Wheel - Opener Depth Ad-

justments

” on page 6-2. If you require more downward

float of your openers you may want to increase this di-

mension. Keep in mind when this dimension is increased

your upward motion is decreased, limiting the vertical

travel of the openers for running over rocks and other for-

eign objects.

CAUTION!

IF YOUR OPENERS’

VERTICAL TRAVEL IS DECREASED, CON-

SIDERABLE DAMAGE WILL OCCUR TO

YOUR OPENERS.

If all the spring rods along the drill extend the same dis-

tance above their castings, the drill is level and you should

tighten down the threaded studs on the gauge wheel cyl-

inder. If the spring rod extensions vary in length, the drill

can be leveled with transport wheel and gauge wheel ad-

justments see

"Pull Bar Adjustments"

To summarize: After leveling your drill, it should have

the same dimension from the ground to the box frame

at both ends of each box. These adjustments may

have to be fined tuned after observing the drill in the

field in actual planting conditions.

!

NOTE:

Complete preparations steps 1 through 6 on

page 2-1 before proceeding with this section.

NOTE:

This section describes procedures for leveling the

drill on it’s initial setup. This should be a onetime adjust-

ment and will not be adjusted in day to day operation. If

while using the drill, it appears to be lifting or planting un-

even, check the following before re-leveling the drill. First,

make sure the tongue is running level to the ground while

running in the field

Be sure to check this if the drill has

been switched to a different tractor.

See

"Tractor

Draw Bar Hook-Up"

, page 2-3. Second, check the lift

cylinders. Be sure they are properly bled, are operating

correctly, and do not have internal oil leaks before using

this section to re-level the drill.

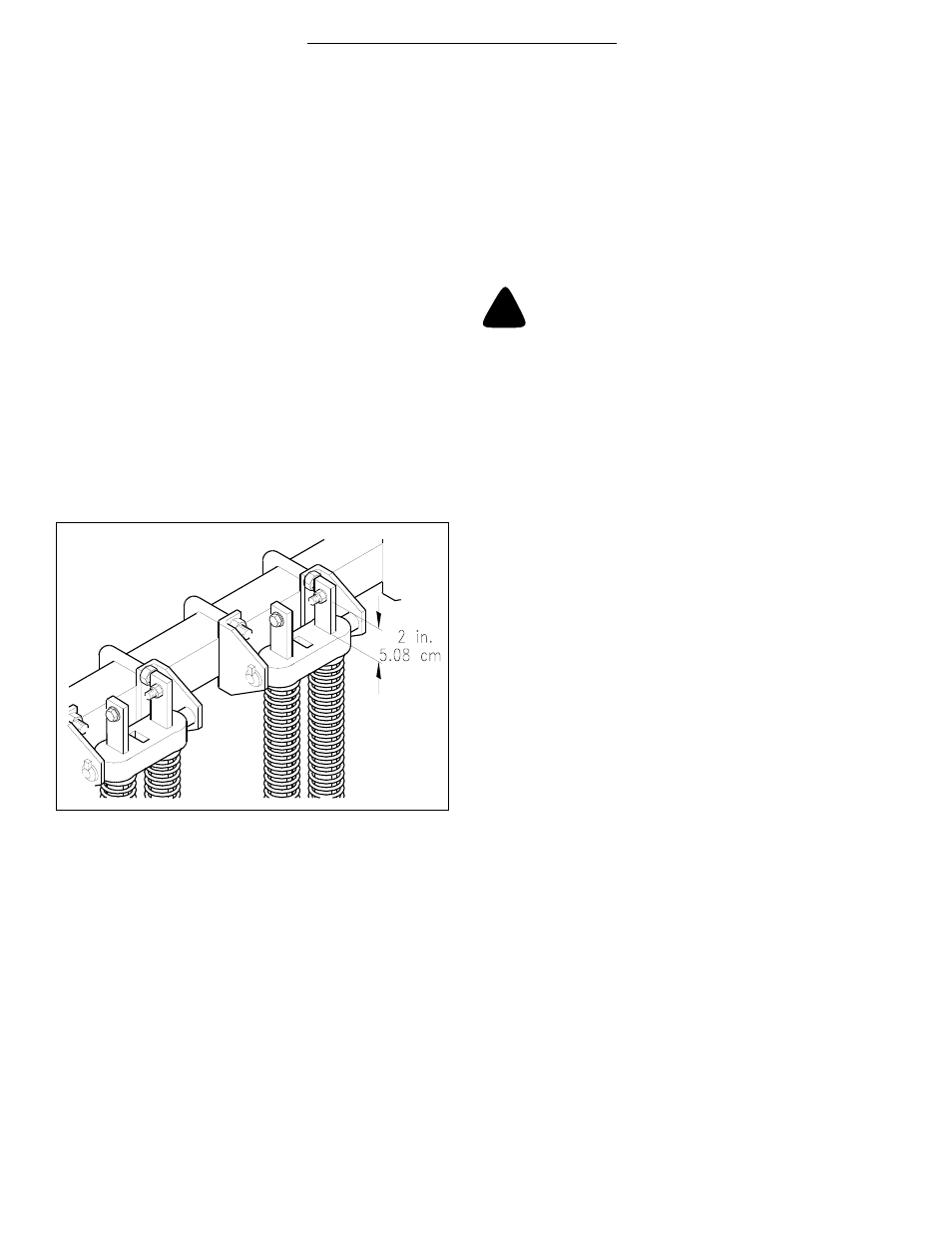

The opener spring rods located along the back of the drill

boxes are indicators of the level of the drill because they

show the amount of down-float on the disk openers and

press wheels. A level drill will have equal opener down-

float from end to end. Check the spring rod cross bolts at

the top of the spring rods to see that they are all extended

about 2 inches above their spring rod castings, Fig. 26.

Opener Spring Rods

Fig. 26

10548