Great Plains 3SF45 Operator Manual User Manual

Page 35

4/8/99

6-3

170-062M

PLANTING DEPTH ADJUSTMENTS

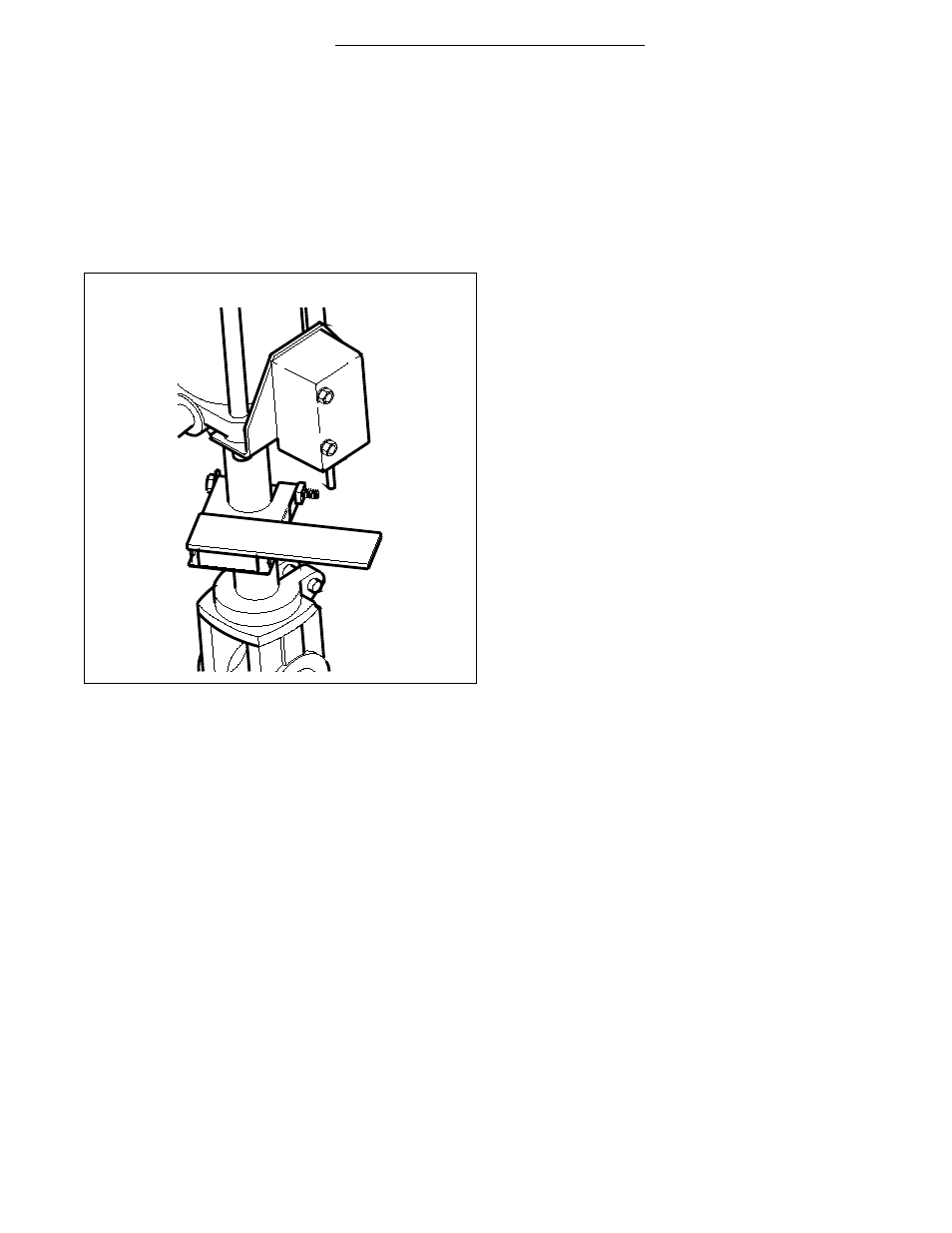

CENTER BOX GAUGE WHEEL HYDRAULIC DEPTH CONTROL ADJUSTMENT

With the top 3-point flex link of the drill in the locked posi-

tion, the amount the drill is lowered will determine the

amount of down float in the openers. This is indicated by

the amount of spring rod sticking above the spring rod

casting when the drill is lowered. Ideally this is about 2".

The boxes should be level front to back.

This can be controlled by the depth stop located on the

master cylinder in front of the drill box at the gauge wheel,

NOTE:

This

DOES NOT

control opener depth, seeding

depth is set with the press wheel adjustment. Refer to

page 6-2 for opener depth adjustments.

The hydraulic depth control allows for variable adjustment

from zero to maximum stroke which controls the height of

your drill boxes in the planting position. The ideal height of

the boxes is 16" from the bottom of the opener mounting

tube to the ground.

To use the depth stop, lower the drill until the bottom of the

opener mounting tube is 16" off the ground. Next loosen

and slide the depth control activator plate up the cylinder

rod as far as possible to where it completely depresses

the plunger on the shut off valve. Secure the stop clamp

at that position. The drill will stop at this height each time

it is lowered.

If the wing boxes stop at a higher or lower position than

the center, refer to "

Bleeding The Lifting Hydraulics

"

NOTE:

Different field conditions may require this stop to

be readjusted.

IMPORTANT:

Be sure to check the clutch drive activa-

tors for correct adjustments after hydraulic depth stops

are adjusted.

Master Cylinder Depth Control Stop

Fig. 25

11803