Great Plains 3SF45 Operator Manual User Manual

Page 25

4/8/99

4-1

170-062M

DRIVE & METERING SYSTEM ADJUSTMENTS

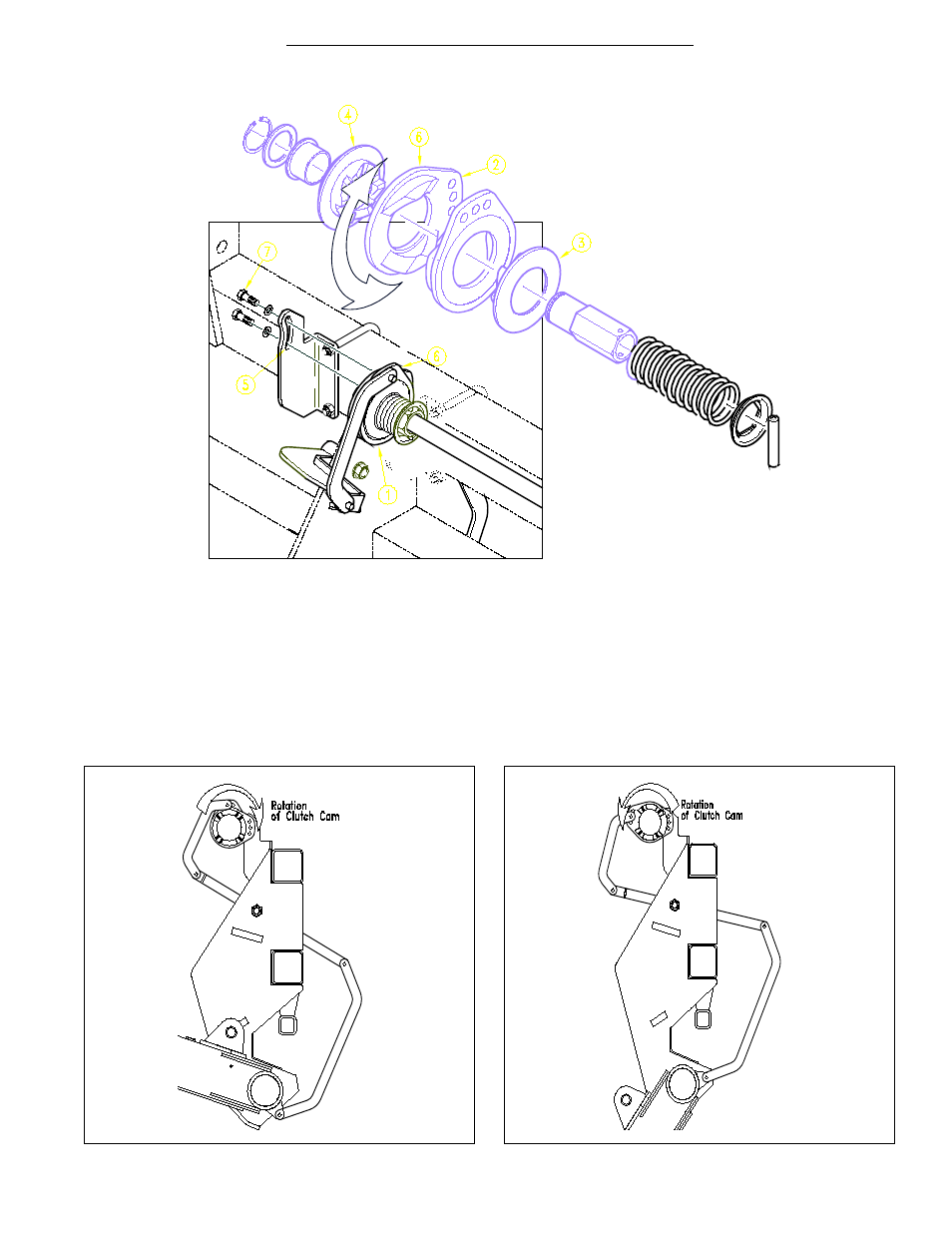

DRIVE SYSTEM CLUTCH

Clutch Activator Engaged - Drill Raised

Fig. 17

Clutch Activator Disengaged - Drill Lowered

Fig. 18

11817

11818

In Fig. 16 the main drive clutch (#1) on your drill is a me-

chanical release - jaw style design which may require

some adjustments before using your drill. Raise the drill

to the transport position, Fig. 17. Check between the two

cam plates (#2) which disengage the jaws (#3) & (#4) of

the clutch halves. The clutch jaws (#3) & (#4) should be

completely separated at this point.

Adjustments can be made to the cam plate (#6) by loos-

ening the bolts (#7), and nuts (#8) in the slotted box brack-

et (#5). By loosening the cam plate (#6) and rotating it

clockwise it will cause the clutch to disengage quicker and

rotating the cam plate counterclockwise will cause the

clutch to disengage slower when raising the drill.

Whenever adjusting the clutch, check to be sure the

clutch jaws (#3) & (#4) are engaged completely when the

drill is lowered to the field position, Fig. 18. The clutch

jaws (#3) & (#4) should also be completely disengaged

when the drill is raised for transport.

11882

Jaw Clutch Adjustment

Fig. 16