Air brakes assembly – Great Plains DVN8324 Assembly Manual User Manual

Page 32

28

8315-8324DVN

Great Plains Manufacturing, Inc.

550-466Q-ENG

11/25/2013

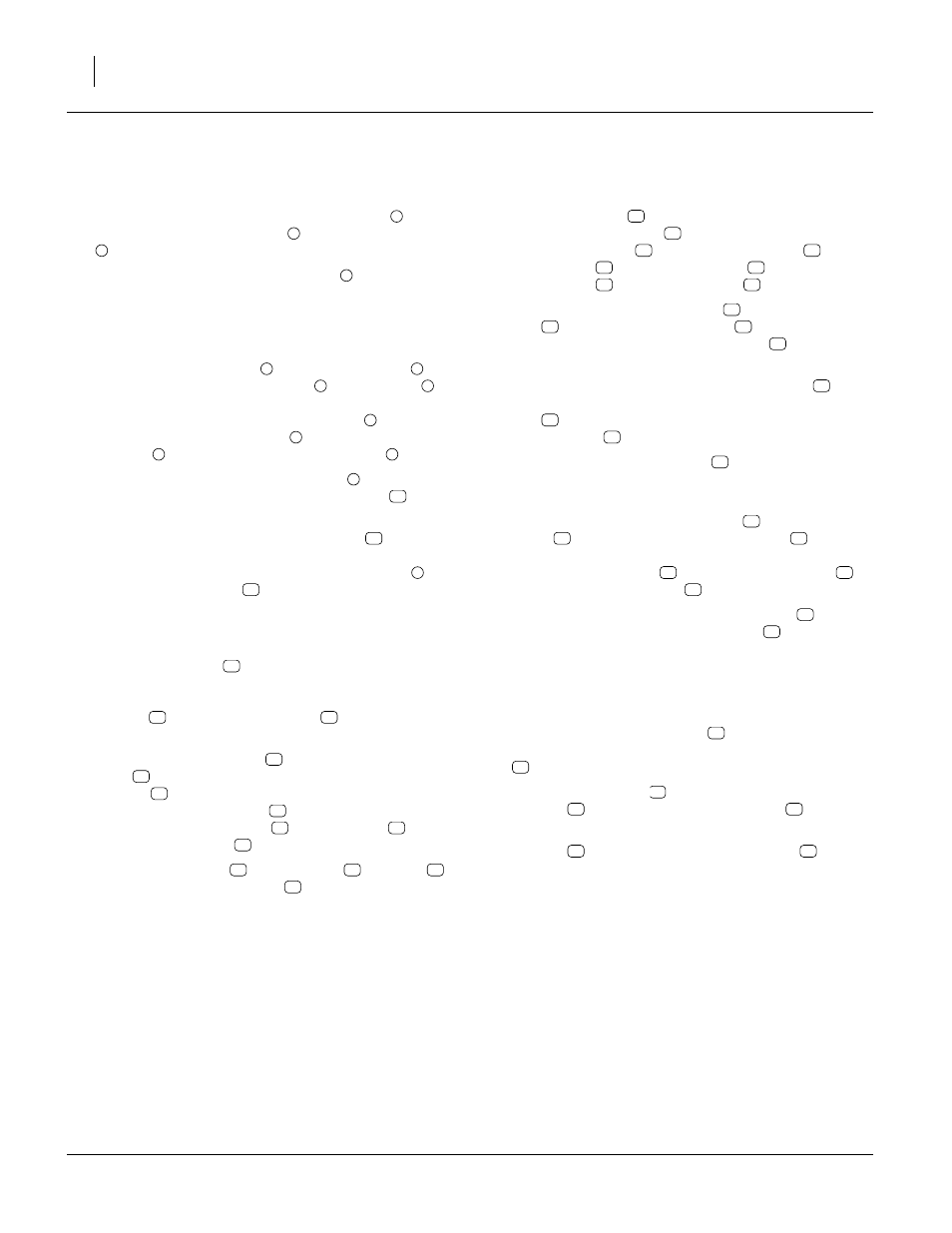

Air Brakes Assembly

135.Start by installing the air/hydraulic booster

to left

side of fold stop using plate

, 5/16 x 3 3/4 hex bolt,

5/16 lock washer and 5/16 nut.

Note: Be sure to install copper gaskets

as shwon.Left

side is shown on brake spindle assemblies, but

right side will be installed the same way. Be sure

the brake spindle assembly were installed with the

brake cylinder towards front of machine.

136.Install invert flare fitting

with copper gasket

into

rear of the air/hydraulic booster

. Banjo fitting

may be installed into left and right wheel hub assem-

bly, brake cylinders with copper gasket

on each

side. Secure with banjo bolt

. The banjo fitting

adapter

is installed into the banjo fitting

.

137.Mount the flare brass fitting with tab

to the center

plate with two holes, with 5/16 x 1 hex bolt

, 5/16

lock washer and 5/16 nut.

138.Now route the four 1/8” dot brake lines

. Fasten

into fittings as shown. The two brake lines that run

from the booster back to the flare brass fitting

need the 3/16” union

installed to splice them

together.

139.Fasten brake lines up along frame close to where

the hydraulic hoses go. They need to be fastened

with the cable ties

as needed. Fasten brake lines

along back of frame tube and along torque tube gus-

sets where the holes are drilled using 3/8 hose

clamps

with 5/16 x 1 hex bolt

, 5/16 lock

washer and 5/16 nuts.

140.Mount the tank brackets

with 1/2 x 2 1/2 x 3 1/2 u-

bolts

, 1/2 lock washers and 1/2 nuts. Attach the

air tank

to the bottom side od the tank brackets

with 3/8 x 1 1/4 hex bolts

, 3/8 lock washers and 3/

8 nuts. Install brass plugs

, 3/4 pipe plug

to rear

of tank and petcock

to bottom of tank.

141.Attach brass fitting

, brass nipple

, adapter

and emergency valve relay

to front of tank.

142.Attach adapters

to right and left side of relay

valve. Fasten adapter

to front of relay valve.

Attach brass plug

into lower left adapter

. Install

brass fitting

into upper adapter

. Attach the 3/8

brass fitting

in the brass fitting

.

143.Fasten one of the brake filters

to the 3/8 brass fit-

ting

. Fasten other brake filter

to front side of

other filter with 5/16 x 3 1/2 hex bolts

, 5/16 lock

washers and 5/16 nuts.

144.Now attach the five, 3/8 x 3/8 brass elbows

to

locations shown in drawing. Attach two 1/2 x 1/2 fit-

ting

to the air line holder. Attach three 1/2 x 3/8

brass fittings

to locations shown.

145.Run the 3/8 nylon brake line

as shown. Cut each

piece to length needed. Be sure to hook into the cor-

rect fittings.

146.Attach the 3/8 air coil hose (blue)

, to top 1/2 x 1/2

fitting

. Fasten the air gladhand (blue)

to other

end of blue hose. Repeat the same procedure for the

3/8 air coil hose (red)

and air gladhand (red)

to

the lower 1/2 x 1/2 fitting

.

147.Attach the two gladhand storage holders

to the

air line holder, with 5/16 x 1 hex bolt

, 5/16 lock

washer and 5/16 nut.

Note: Be sure brake lines are secured to where they

won’t get pinched when raising machine up and

down.

148.Attach wheel chock holders

(optional) to plates

on outside of center frame with 1/2 x 1 1/2 hex bolts

, 1/2 lock washers and 1/2 nuts.

149.Slide wheel chocks

onto pegs of wheel chock

holders

, secure with chain fasteners

.

150.Clean area on side of frame beside wheel chock

holders

and place wheel chock decals

onto

frame.

151.Tighten all bolts to specs, See “Torque Values

1

2

3

4

5

4

1

6

4

7

8

6

9

10

11

9

13

14

12

10

15

16

17

18

19

20

21

22

23

24

25

24

26

27

24

28

24

29

28

30

29

30

31

32

35

33

34

36

35

37

38

39

35

40

10

41

42

43

41

44

41

44