Install k-flex, Install magnum shank, Install k-flex install magnum shank – Great Plains DVN8324 Assembly Manual User Manual

Page 20

16

8315-8324DVN

Great Plains Manufacturing, Inc.

550-466Q-ENG

11/25/2013

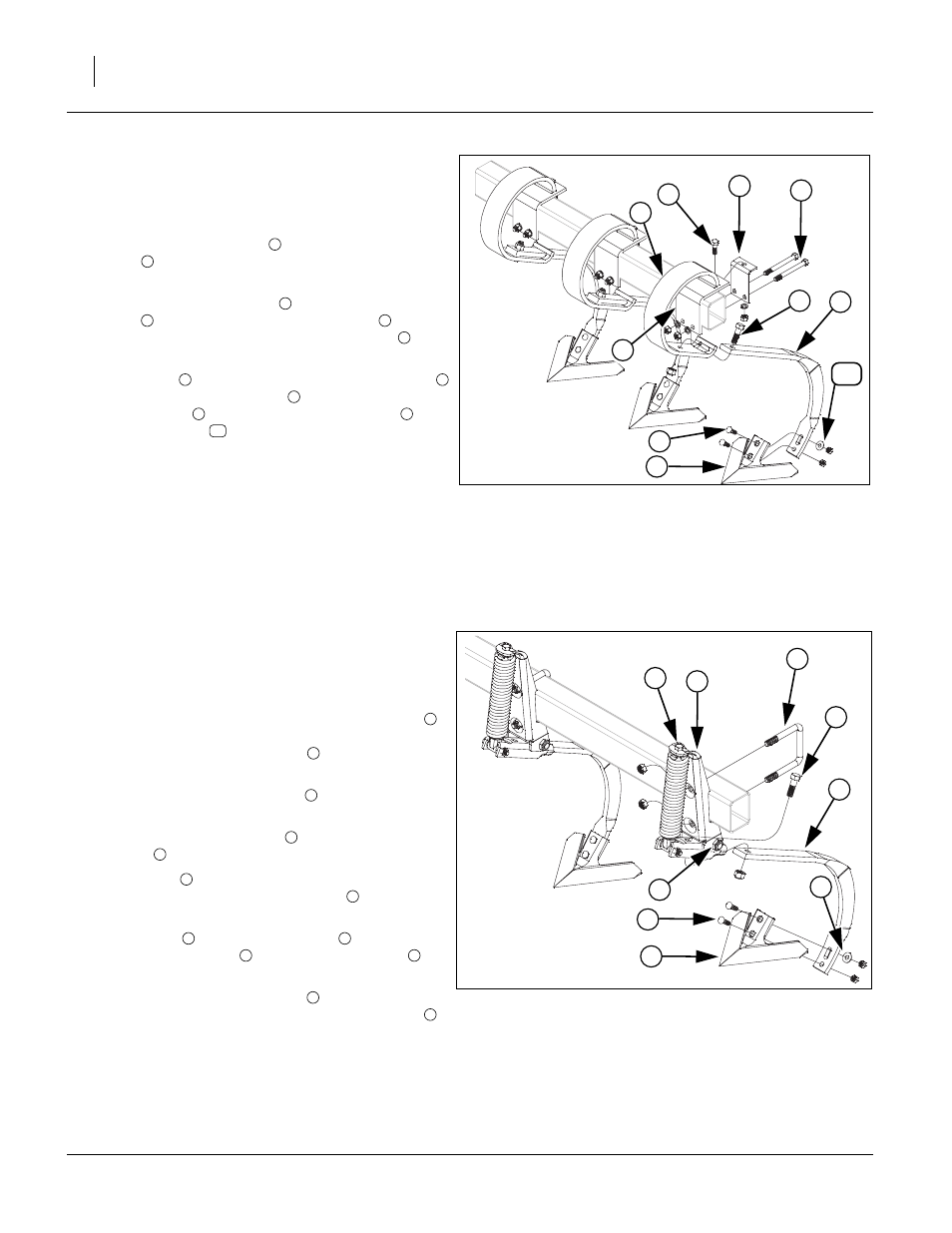

Install K-Flex

Note: See machine layouts in “Operator’s Manual” for

proper shank placement.

Refer to Figure 10

57. Slide k-flex shank mount

through slot in k-flex

clamp

. Slide these two parts over frame tube in

proper location.

58. Align top hole in k-flex clip

with top hole in k-flex

clamp

, secure with 1/2 x 1 1/2 hex bolt

, 1/2 lock

washer and 1/2 nut. Install 1/2 x 5 hex bolts

, 1/2

lock washers and 1/2 nuts.

59. Slide shank

through slotted hole in k-flex clamp

,

secure with 5/8 x 2 hex bolt

and 5/8 top lock nut.

Attach sweep

with 7/16 x 1 3/4 plow bolts

, one,

7/16 flat washer

and 7/16 nylock nuts.

60. Tighten all bolts to specs, See “Torque Values

Install Magnum Shank

Note: See machine layouts in “Operator’s Manual” for

proper shank placement.

Refer to Figure 11

61. Position pre-assembled shank mount assembly

over front of frame tube in proper location. Secure

with 5/8 x 4 1/32 x 4 3/4 u-bolt

and 5/8 top lock

nut.

62. Be sure the 3/4 nylock jam nut

is loose enough for

shank cradle to pivot.

63. Loosen 1/2 x 1 1/2 hex bolt

clear up to get 5/8 x 2

hex bolt

installed.

64. Slide shank

into shank cradle until holes are

aligned, secure with 5/8 x 2 hex bolt

and 5/8 top

lock nut.

65. Align sweep

with holes on shank

, secure with 7/

16 x 1 3/4 plow bolts

, one, 7/16 flat washer

and

7/16 nylock nuts.

66. Re-tighten 1/2 x 1 1/2 hex bolt

until threads bot-

tom out. Be sure and tighten 3/4 nylock jam nut

until threads bottom out to insure that hole doesn’t

wear excessively.

67. Tighten rest of bolts to specs, See “Torque Values

Figure 10

K-Flex Assembly

41667

8

9

6

2

7

5

3

4

1

10

1

2

3

2

4

5

6

1

7

8

9

10

Figure 11

Magnum Shank Assembly

41668

6

1

5

3

9

7

2

8

4

1

2

3

4

6

5

6

7

5

8

9

4

3