Dismount hopper, Caution – Great Plains 401-516A Installation Instructions User Manual

Page 8

6

YP Pressure Relief Kits

Great Plains Manufacturing, Inc.

401-514M

12/28/2007

Dismount Hopper

!

CAUTION

You will be handling the bottom components of the hopper, and

any remaining moisture may contain residual seed treatments.

This update cannot be performed with a hopper cradled

on a planter, as the planter airbox obstructs access from

below. Consult the planter Operator manual for hopper

removal instructions.

5.

While waiting for the hopper to dry, prepare a suit-

able work location. Use a level, dry, well-lighted area.

Pick a location with a clear surface beneath, so that

any dropped tools or parts can be easily located.

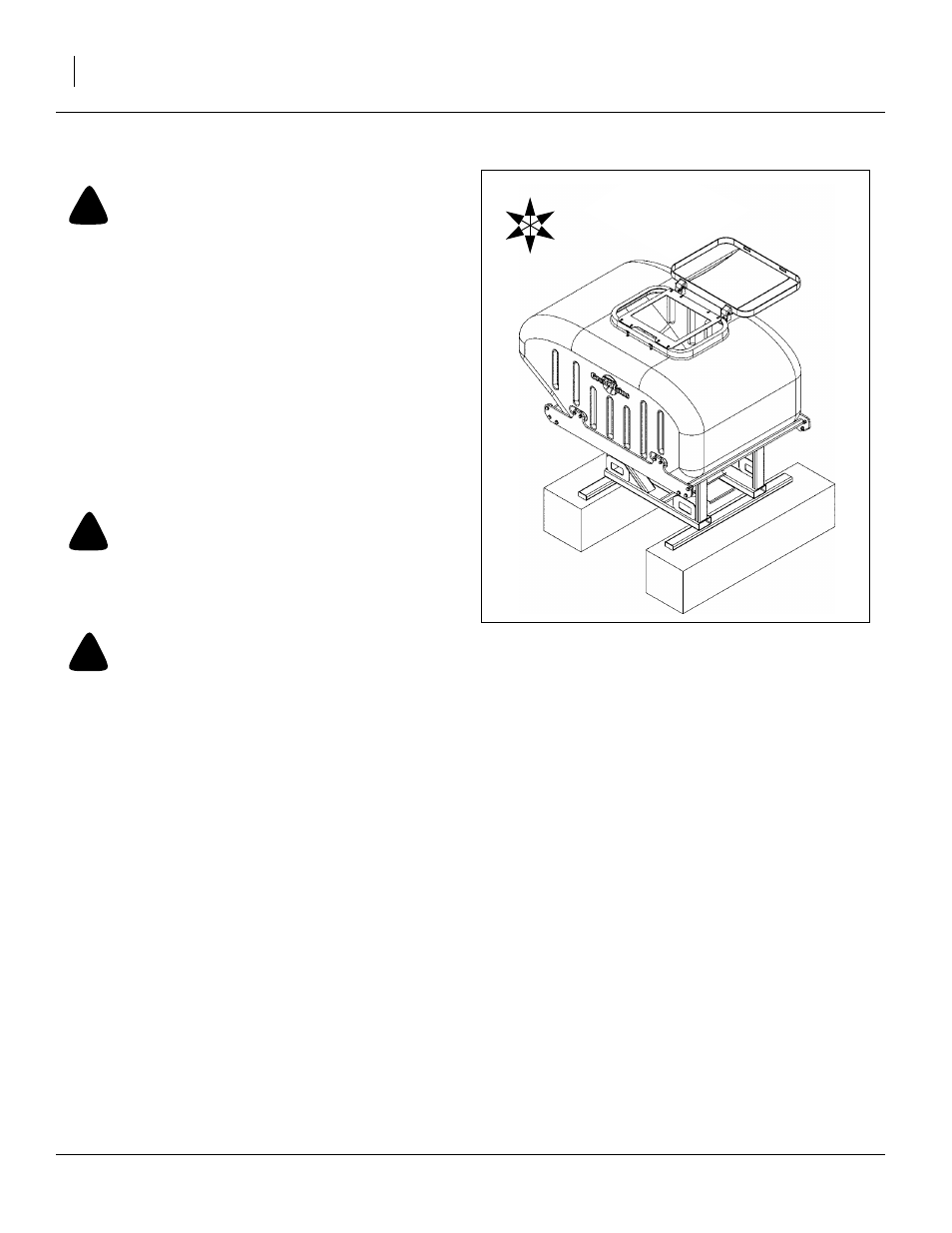

For work access to the bottom of the hopper, the

assembly needs to raised at least 18in (46cm). One

method, as shown in Figure 3, is to rest it on blocks

or supports under the lateral tubes of the structure.

!

CAUTION

Use adequate supports.

Make sure each support can safely support at least 150% its

apparent share of the weight. See step 6 for hopper weights.

Do not perform this work in high wind.

!

CAUTION

Anchor the hopper laterally.

Make sure that workers on ladders at later steps cannot push

or tip the hopper off the supports.

6.

If the hopper to be updated is presently on a planter,

use a suitably rated forklift or hoist to remove the

hopper.

A 403-143K or 403-226K 82 bu hopper weighs 1200

pounds (544 kg) empty. Allow another 400 pounds

(181 kg) for two workers and tools,

for a total of 1600 pounds (726 kg).

A 403-174K 150 bu hopper weighs 1350 pounds

(612 kg) empty. Allow another 400 pounds (181 kg)

for two workers and tools,

for a total of 1750 pounds (794 kg).

7.

Place the hopper in the prepared work location.

Figure 3:

Hopper on Blocks

27354

U

D

L

R

B

F