Insert pipe in hopper, Cap and position pipe, Drill 150 bu holes – Great Plains 401-516A Installation Instructions User Manual

Page 15: Step 53

Great Plains Manufacturing, Inc.

Installation Instructions

13

12/28/2007

401-514M

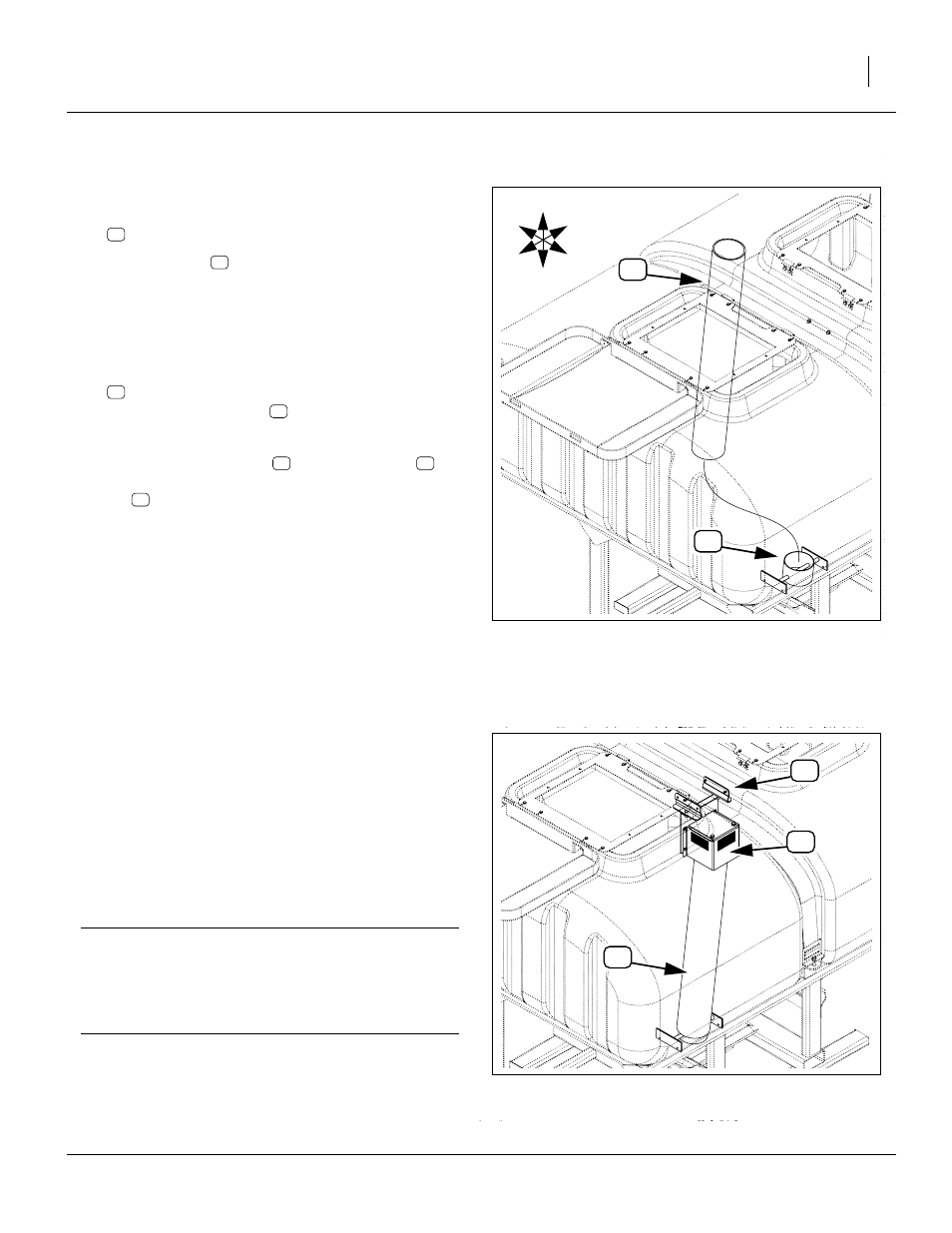

Insert Pipe in Hopper

Refer to Figure 16

50. Select one new:

403-427D 150 BU AIR PRESSURE PIPE

51. Insert the pipe

into the hopper and slide it over

the lower pipe support weldment. Have a second

worker hold it, or temporarily lean it against the back

of the hopper.

Cap and Position Pipe

52. Select the:

403-242S UPPER PIPE SUPPORT WELDMENT

with the angle brackets

Refer to Figure 17

53. Place the cap assembly

on top of the pipe

and

maneuver it so that the four holes in the angle brack-

ets

align with the marks for the holes to be drilled.

It may be necessary to temporarily remove one

angle bracket in some cases.

If all four holes cannot be aligned, align to the for-

ward holes. If both left and right side forward holes

cannot be aligned, use the left forward hole.

54. Make sure the angle bracket bolts are finger tight,

and make final marks for drilling. Fore-and-aft loca-

tion of the holes is not critical, but if a hole needs to

be re-marked, make sure the vertical position is on

the centerline marked at step 49.

Drill 150 bu Holes

These holes need to be drilled from the inside, as the

exterior channel of the stiffener rib is not wide enough for

most portable drills.

55. Swing the pipe assembly clear.

56. Drill pilot holes. Re-check hole placement and drill

final holes.

57. Sweep out any drill swarf that might eventually clog a

seed meter.

IMPORTANT !

If any error is made in hole drilling, close the hole with

a

5

⁄

16

in or 8mm bolt, washers and nut, coated with

silicone sealant. A hole left open adversely affects

seed delivery.

Figure 16:

Insert 150 bu Pipe

27364

U

D

L

R

B

F

Figure 17:

Position 150 bu Pipe

27366