Install 150 bu upper components, Mark holes for drilling, Ud b f – Great Plains 401-516A Installation Instructions User Manual

Page 14

12

YP Pressure Relief Kits

Great Plains Manufacturing, Inc.

401-514M

12/28/2007

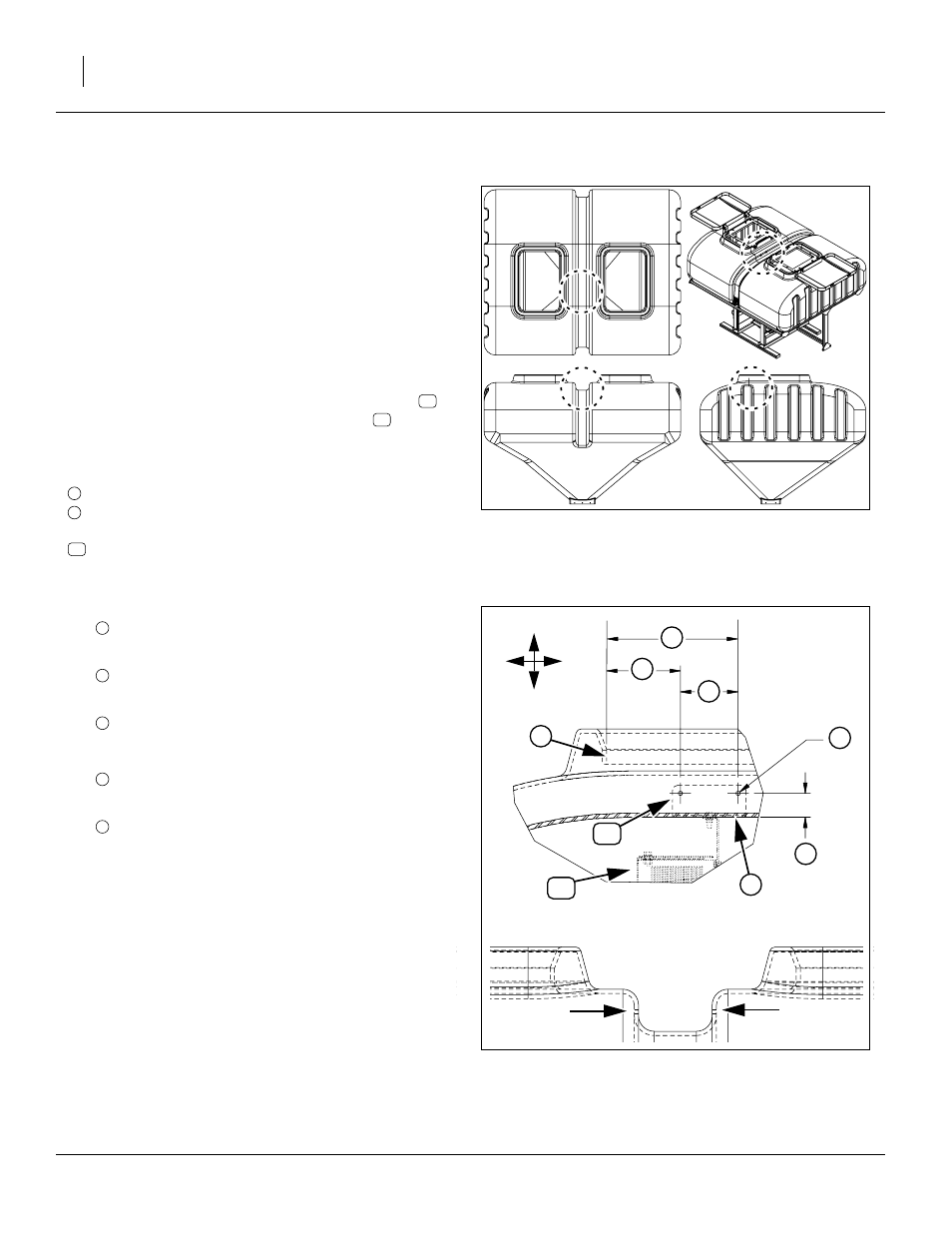

Install 150 bu Upper Components

If you are updating an 82bu hopper, use the instructions

at “Install 82 bu Upper Components” on page 10.

Refer to Figure 14

In the 150 bu hopper, the upper tube support mounts to

the stiffener rib molded into the hopper. Four holes, two

each side, need to be drilled.

This work is most easily accomplished from the walk-

board, while the hopper is on the planter.

which depicts a view from the right side above a view from

the rear. The eventual location of top tube support

is

shown in dotted line, and the angle bracket

shown in

dashed line.

Hole locations are in the side walls of the center stiffener

rib. Measurements are referenced from:

front face, rear lip of tank top openings

underside of center stiffener rib

After installation, the bottom edge of the angle bracket

is flush with the underside of the center stiffener rib.

Mark Holes for Drilling

45. Holes are above the underside of center stiffener rib:

2.28in, 2

9

⁄

32

in, 5.79cm

46. The rear holes are located forward of the lip at:

7.02in, 7

1

⁄

64

in, 17.82cm

47. The front holes are forward of the rear holes by:

5.50in, 5

1

⁄

2

in, 13.97cm

For reference, the total distance from the lip to the

forward holes is:

12.52in, 12

33

⁄

64

in, 31.79cm

48. Mark the hole centers. Hole diameter is:

0.41in,

13

⁄

32

in, 10.4mm

49. Use a 16in (41cm) straight edge to mark a line

between the hole centers, and about 2in (5cm) on

either side.

Note: Depending on the hopper and part tolerances,

these may not be the final hole positions. The final

holes are marked and drilled beginning at step 53.

Figure 14:

150 bu Hopper Drill Region

27359

Figure 15: Side / Rear View

150 bu Drill Holes

27360

U

D

B

F

B

C

H

E

1

2

A