Great Plains 3000 Operator Manual User Manual

Page 23

21

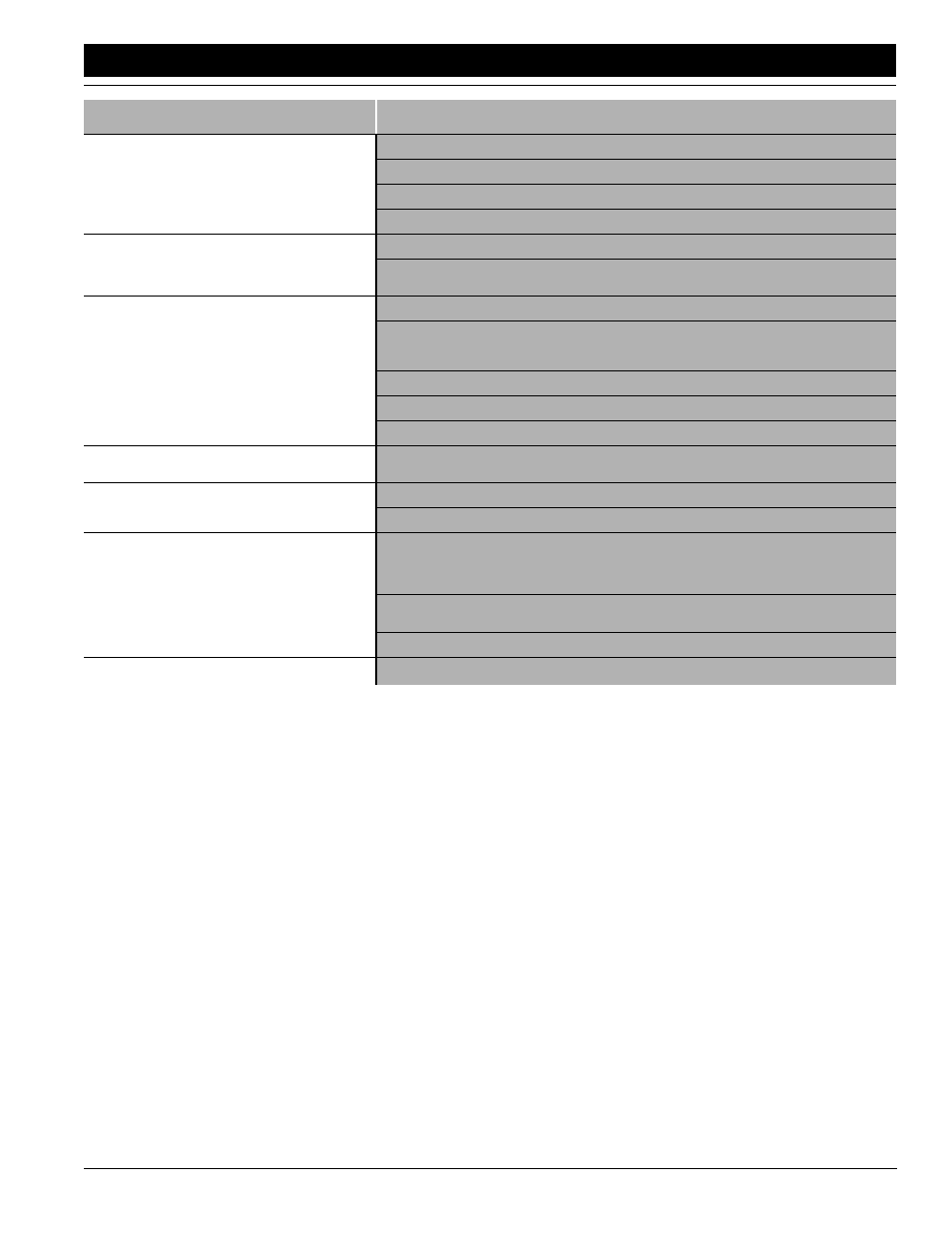

Section 4 Troubleshooting

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

Great Plains Mfg., Inc.

Press wheel or openers plugging

Consider soil conditions–may be too damp or wet.

Reduce down pressure on openers. Down-Pressure Springs, “Adjustments,” page 12.

Do not back up or allow drill to roll backward with openers in the ground.

Check Seed-Lok wheel. If conditions are too wet, you may need to remove the wheels.

Seed-cup sprockets locked up or twisted feeder

drive shaft

Check for foreign material stuck in the seed-cup sprockets.

Check for dried liquid insecticide in seed cups. Remove the build up by disassem-

bling each seed cup and scraping the foreign substance from the turning surfaces.

Hydraulic marker functioning improperly

Check all hose fittings and connections for air or oil leaks.

The chain on the folding three-section marker should be slack when the marker is

both fully extended and fully raised. Refer to Marker Adjustments, “Adjustments,”

page 19.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

Open needle valve, cycle markers slowly and reset needle valve if plugged.

Drill is not pulling level (parallel to ground, front to

rear)

Readjust top hitch link to level drill.

Gauge wheel leans to left or right

Realign brackets where gauge wheel is attached to main frame by adjusting u-bolts.

Check if axle bearings are securely attached to gauge-wheel arm.

Marker blade does not mark

Check that the marker folding linkage has enough slack to allow the marker disk to

drop into field depressions. Maximum down float should be limited by the slot at the

rod end of the marker cylinder–not by the chain. Refer to Marker Adjustments,

“Adjustments,” page 25.

Reverse the blade to pull or throw dirt. Refer to Marker Adjustments, “Adjustments,”

page 25.

Try the optional notched blade available through your Great Plains dealer.

Chain

Be sure retainer clip is facing opposite way of chain travel

Problem

Solution