Gauge-wheel adjustment – Great Plains 3000 Operator Manual User Manual

Page 13

11

Section 3 Adjustments

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

Great Plains Mfg., Inc.

Section 3

Adjustments

Gauge-Wheel Adjustment

Gauge-wheel adjustments affect the operating height of

your drill, and drill height directly affects the working range

of the openers. The drill must be adjusted so your openers

can travel up and down and follow the ground contour. Ini-

tially adjust the gauge wheels so the bottom of the opener

mounting tube runs 18 1/4 inches above ground.

To adjust drill height:

1.

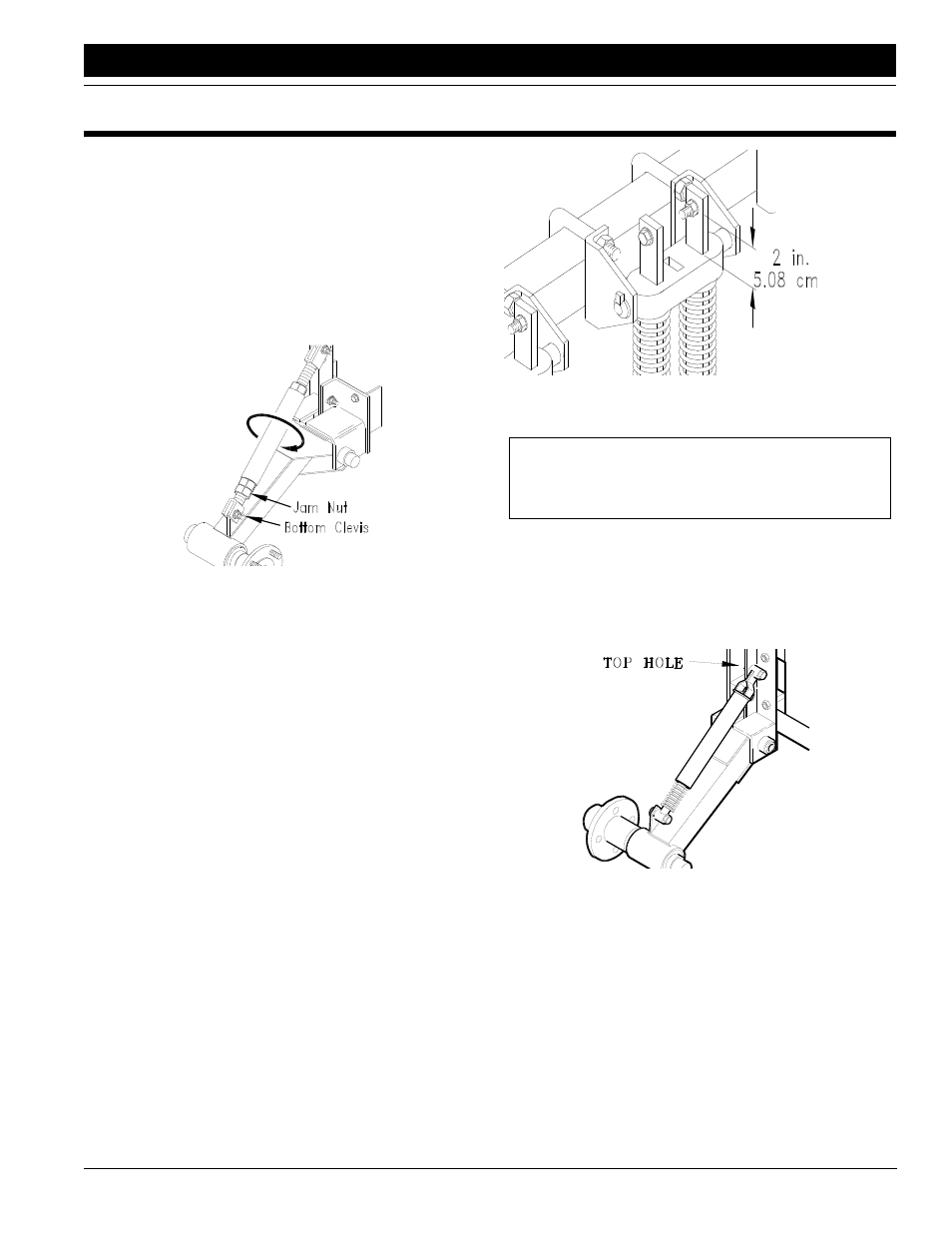

Loosen the jam nut near the bottom clevis of each

gauge-wheel turnbuckle. Refer to Figure 3-1.

Figure 3-1

Gauge Wheel Turnbuckle

2.

Bolt the upper clevis in the upper mounting hole.

3.

Set the turnbuckle length. Turn the turnbuckle to

shorten or lengthen as necessary. Initially set the

length to 20 3/8 inches between pin centers to

achieve the 18 1/4-inch dimension mentioned above.

When adjusting the turnbuckle, remember:

•Lengthening the turnbuckle raises the drill and allows

less downward float of the openers.

•Shortening the turnbuckle lowers the drill and allows

less upward float of the openers.

NOTE: Remember that lowering the drill increases the risk

of opener damage on rocks or obstructions.

4.

After adjusting both turnbuckles, be certain they are

the same length, then tighten the jam nuts.

5.

After setting the turnbuckles, level the drill with the top

hitch link. When the drill is level, the gap between the

spring-rod casting and the cross bolt will be about 2

inches. See Figure 3-2. This is a general dimension

that will vary with the amount of down pressure re-

quired for your planting conditions.

Figure 3-2

Normal Spring Rod Setting, Drill Level

For some drill applications, you may want to equip your

drill with two spring-loaded links (part number 120-106A)

or a slotted link (part number 120-171A). Mount the links

in the top hole of the gauge wheel bracket as shown in Fig-

ure 3-3. You do not need to adjust the spring-loaded or

slotted links.

Figure 3-3

Spring-Loaded Links For No-Till Drilling

10546

10548

IMPORTANT: Do not use the links to adjust opener

depth. To achieve desired seeding depth, refer to Seed-

ing Depth, “Adjustments,” page 12.

10547