Great Plains NTA3010 Operator Manual User Manual

Page 56

52

NTA3010 and NTA3510

Great Plains Manufacturing, Inc.

160-219M-A

2014-03-26

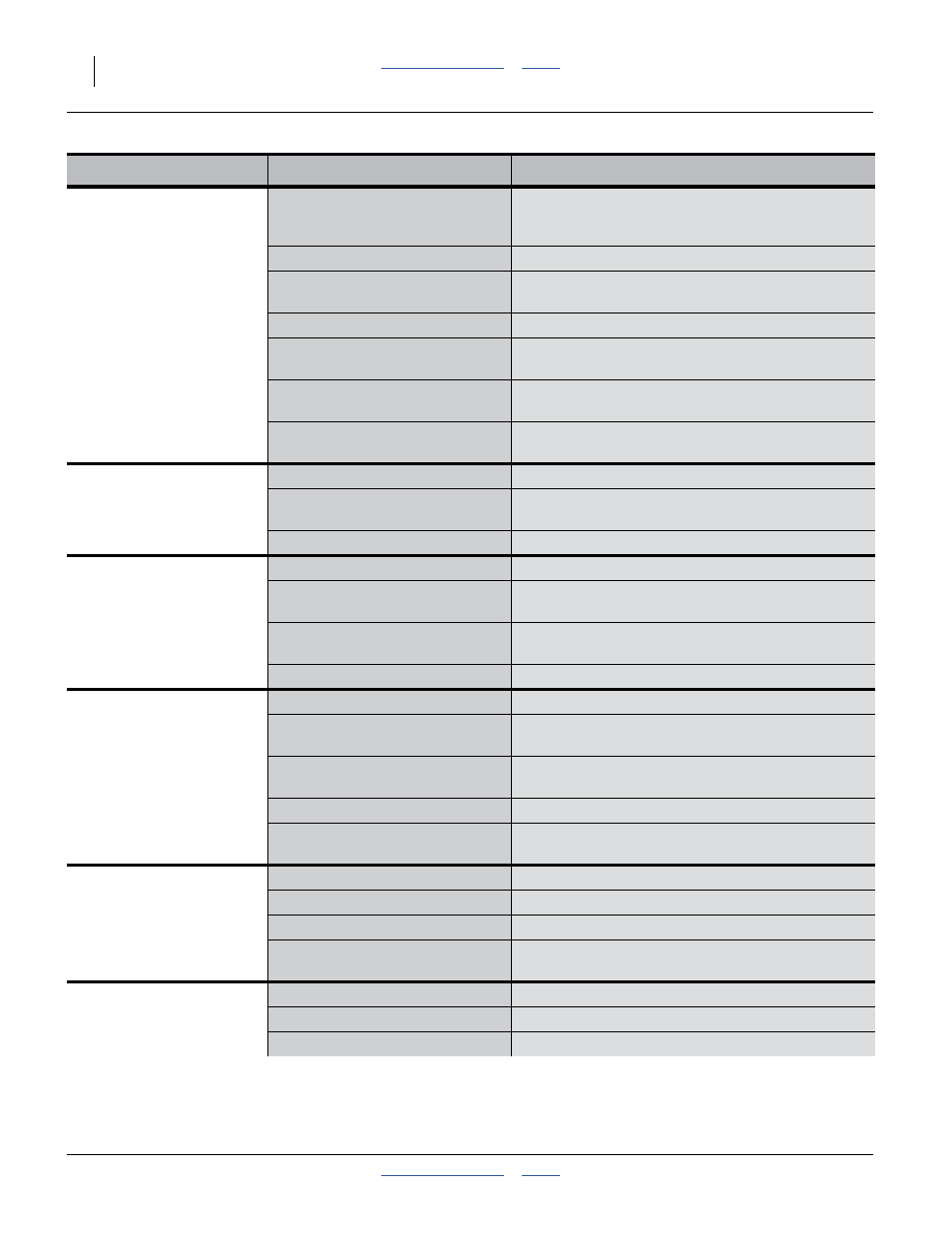

Uneven depth across

drill

Drill not level

See “Level Frame Side to Side” on page 19.

Lift cylinders may also need bleeding. See

“Bleeding Lift Hydraulics” on page 17.

Cylinders out of phase

Re-phase cylinders

Weight transfer inoperative

Check valve handle, monitor soft key and gauge

reading

Tire pressures not equal

Check and inflate

Weight transfer to wings too high

or too low.

See “Weight Transfer” on page 42.

Weight circuit flow reversal

Check lever position and hookup. Recheck fan

rotation on any changes.

Press wheel heights not all the

same

Set T-handles the same.

Drill height changing or

creeping

Air in system

See “Bleeding Lift Hydraulics” on page 17.

Worn lift components.

If a cylinder is leaking oil past a seal, consult the

Parts Manual and replace the seal.

Tractor hydraulic malfunction

Confirm by using a different circuit for lift.

Seeding pattern

skipping rows

Plugged openers

Check that disks turn freely. Check scrapers.

Seed hose plugged

Stop and raise drill with fan running. Hand-crank

meter and check for rows not delivering seed.

Hose disconnected or leaking

Check hose path from front cart meter to row unit.

Check for leaks in hoses.

Seed tube plugged

Check for debris and pest nests in tube.

Primary seed hoses are

plugging

Fan speed too low

Increase hydraulic flow to circuit.

Erratic fan speed

Observe rpm reported by monitor, then check for oil

flow surging by tractor.

Flow not stopping when raised

Have observer verify that meter gear rotation

ceases when drill is moving while raised.

Damaged hoses

Inspect and repair as needed.

Sharp bends or too much slack in

hoses

Re-route hoses for minimum necessary slack and

no sharp bends.

Secondary seed hoses

plugging

Fan speed too low

Increase hydraulic flow to circuit.

Damaged hoses

Inspect and repair as needed.

Debris in seed or hoses

Disconnect, inspect and clear.

Sharp bends or too much slack in

hoses

Re-route hoses for minimum necessary slack and

no sharp bends.

Openers plugging

Disks need adjustment

See “Disk Blade Adjustments” on page 45.

Scrapers need adjustment

See “Disk Scraper Adjustments” on page 46.

Conditions too damp

Wait for drier weather.

Problem

Cause

Solution