Adjusting disc contact, Disk scraper adjustments – Great Plains NTA3010 Operator Manual User Manual

Page 50

46

NTA3010 and NTA3510

Great Plains Manufacturing, Inc.

160-219M-A

2014-03-26

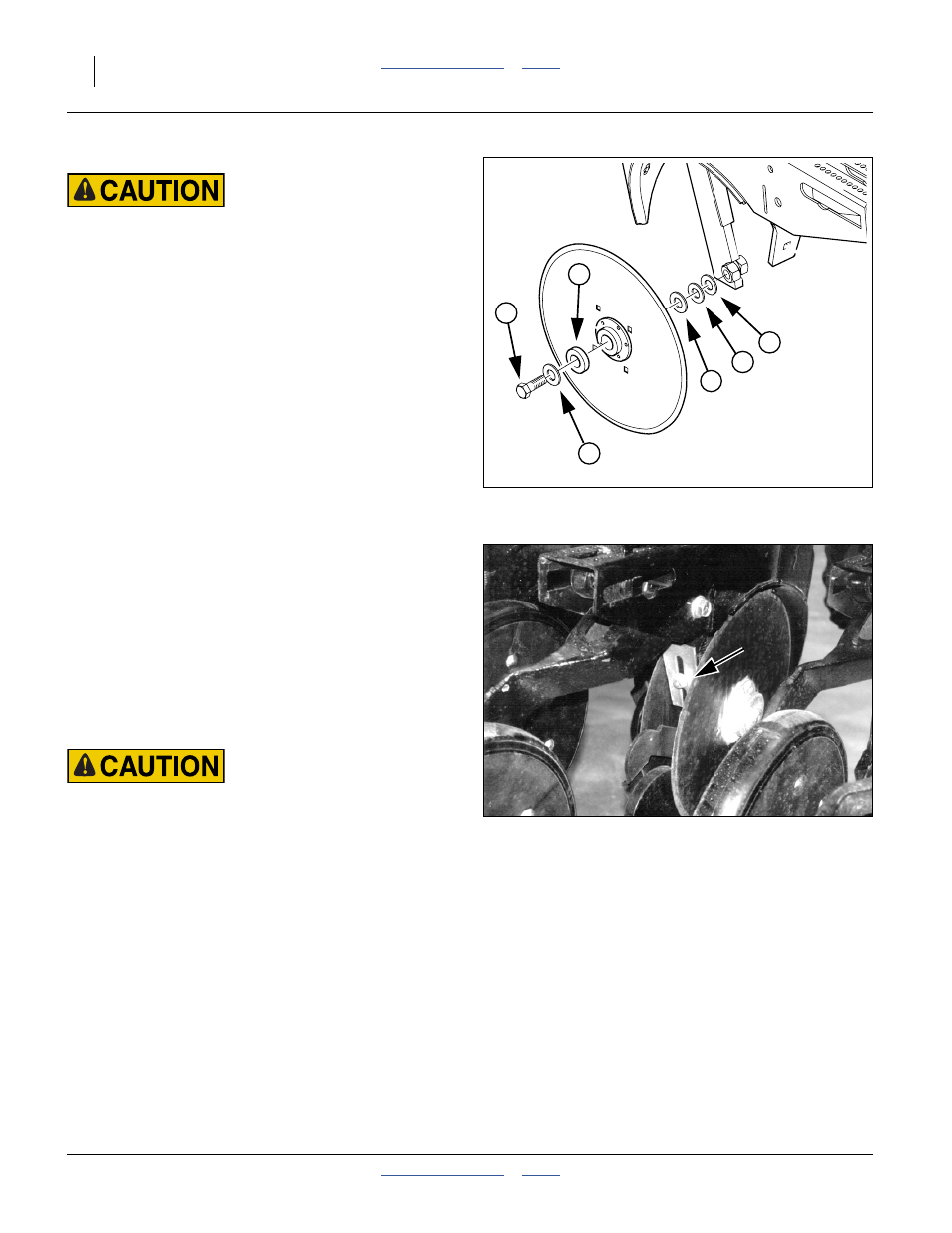

Adjusting Disc Contact

Sharp Object Hazard:

Row unit disk blades may be sharp. Use caution when making

adjustments in this area.

Refer to Figure 53

1.

Raise the drill and install the transport locks.

2.

Remove the bolt retaining the opener disc on one

side. Carefully remove the disc, noting how many

spacers are outside the disk and inside the disk. Do

not lose the hub components and spacer washers.

3.

To reduce the spacing between the discs (the normal

case), move one spacer washer from the inside to

the outside of the disc.

4.

Re-assemble and check disc contact.

Disk Scraper Adjustments

To keep opener disks turning freely, dirt scrapers are

mounted between disks to clean as disks

rotate.Standard 10 Series row units include a

double-disk slotted scraper. A carbide scraper is

available (see “Seed Firmers” on page 60).

Refer to Figure 54

As field conditions vary, scrapers may need to be

adjusted. In damp conditions, lower scrapers. If openers

are not turning freely, raise scrapers. To adjust, loosen

bolt and move scraper as needed.

Sharp Object Hazard:

Row unit disk blades may be sharp. Use caution when making

adjustments in this area.

Figure 53

Adjusting Disk Spacers

26385

2

1

3

3

3

3

Figure 54

Standard Disc Scraper

16163