Great Plains NTA3010 Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

Troubleshooting

51

2014-03-26

160-219M-A

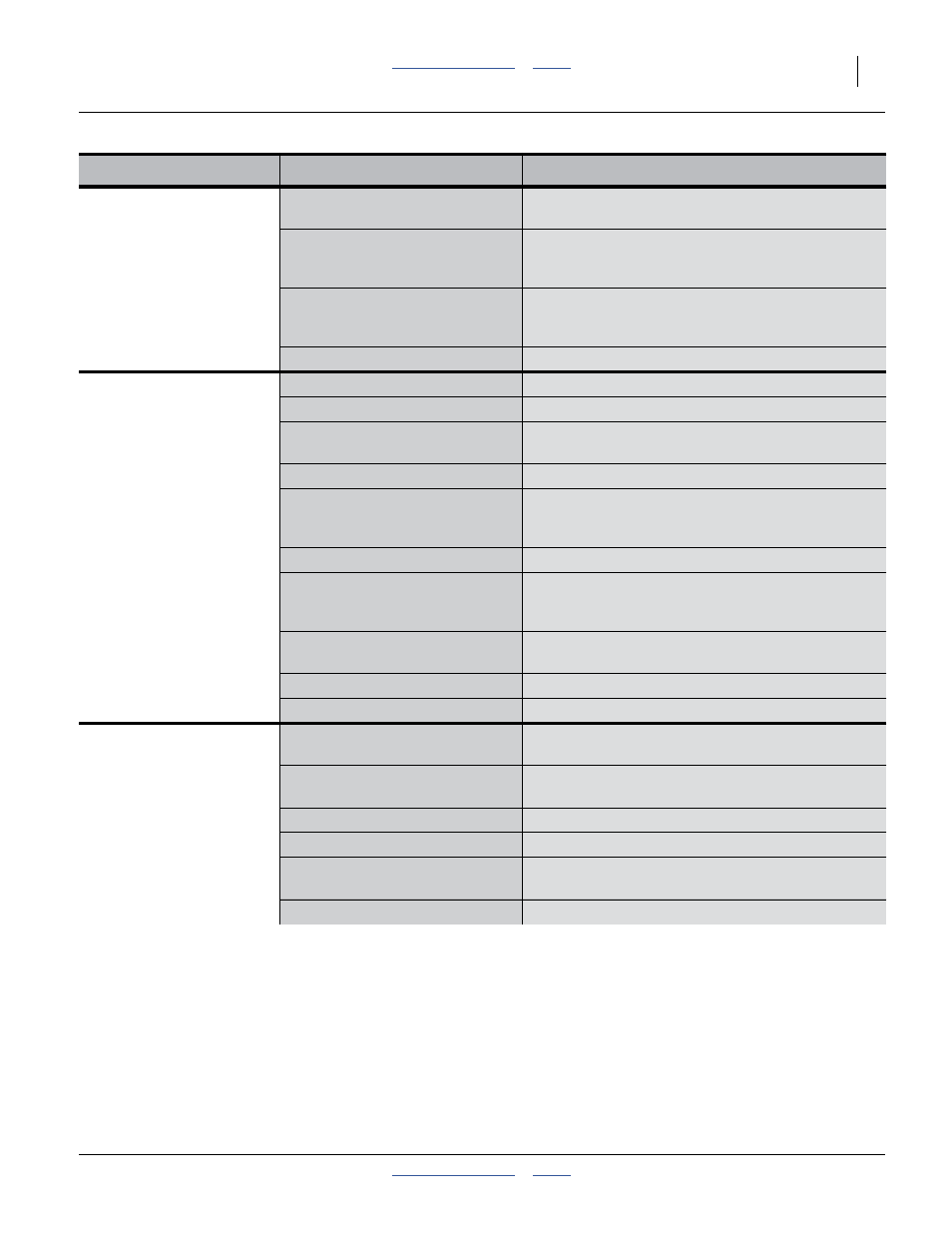

No Seed Flow

Height switch out of adjustment or

failed.

Check, adjust or replace lift switch.

Cart clutch failed

Replace clutch. On an emergency basis, use the

clutch lock-up procedure in the cart Operator’s

Manual.

Cart clutch circuit failed

Replace failed component or cable. On an

emergency basis, use the clutch lock-up procedure

in the cart Operator’s Manual.

Seed rate set to zero

Check seed rate indicator at cart meter(s).

Uneven seed spacing

or uneven stand

Excessive field speed

Reduce speed.

Opener disks slowing

Check that disks turn freely. Check scrapers.

Insufficient down force for low

spots

Increase down force

Row units following terrain

Check row unit down-force.

Air leaks

Check hopper lids, meter seals, manifold caps and

seed hose connections. Adjust latch and/or replace

seals as needed.

Erratic meter clutch

Check for damaged cables and loose connections.

Tower blockage

Check towers for obstructions and plugging.

Blockages sometimes move from port to port in

towers.

Seed hose plugged

Stop and raise drill with fan running. Hand-crank

meter and check for rows not delivering seed.

Unclean seed

Use clean seed.

Seed sticking to firmer

Lock-up firmer or wait for drier conditions.

Uneven seed depth

Excessive field speed

Slow down. Check Seeding Rate Chart for correct

maximum field speed.

Insufficient down force for low

spots

Increase down force

Openers “diving” during no-till

operations

See “Level Frame Front to Rear” on page 20.

Planting conditions too wet

Wait until drier weather.

Problem

Cause

Solution