Troubleshooting – Great Plains NTA3010 Operator Manual User Manual

Page 54

160-219M-A

2014-03-26

50

NTA3010 and NTA3510

Great Plains Manufacturing, Inc.

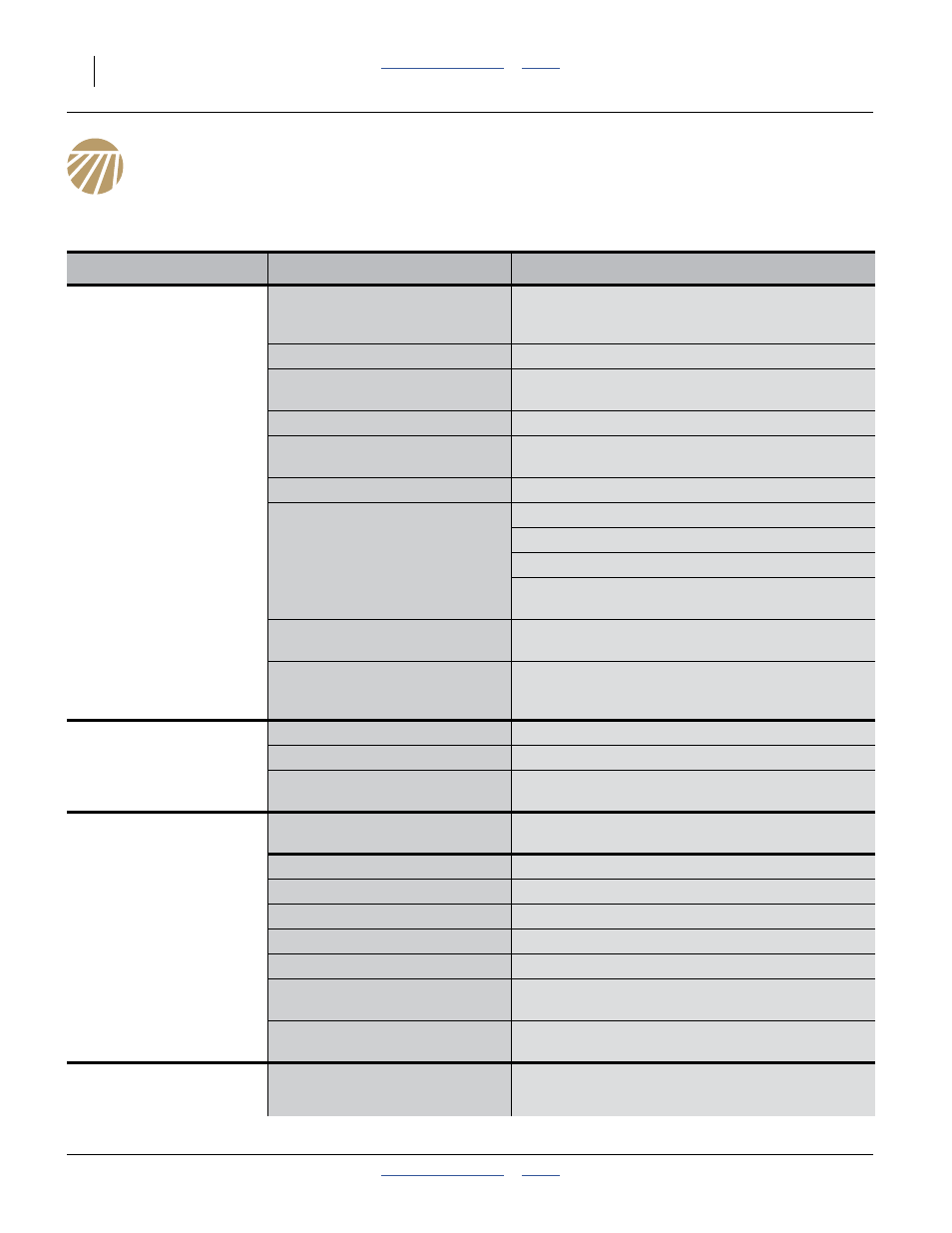

Troubleshooting

This chart primarily covers problems arising from drill

issues, although it does include a few cart items.

Also consult the Troubleshooting chart for the cart.

Problem

Cause

Solution

Planting too little

Air leaks

Check hopper lids, meter seals, manifold caps and

seed hose connections. Adjust latch and/or replace

seals as needed.

Fan speed too low

See “Recommended Fan Speeds” on page 32.

Height switch engaging too high

See “Implement Lift Switch Adjustment” on

page 38.

Excessive field speed

Reduce speed

Excessive gaps between drill

passes

Adjust markers.

Actual field size is different

Verify field size.

Plugged seed hose

Clean out seed tube hose.

Remove excess slack in hoses.

Re-route hoses to avoid sharp bends.

Check that metering is actually stopping when drill

is raised. Adjust or replace lift switch.

Plugged opener seed tube

Lift up drill, expose bottom of seed tube and clean

out.

Obstruction in meter or seed

tubes (foreign material or

uncleaned seed)

Clean meter and seed tube.

Planting too much

Meter setting too high

Re-check against chart & calibration.

Actual field size is different

Verify field size.

Excessive overlap or irregular

shaped field

Adjust marker.

Seed visible on ground

behind drill

Seed depth too shallow

Check and reset coulter depth, press wheel depth,

and down-forces.

Coulters not aligned with openers Check and re-align coulter at frame mount.

Down force too low

Check coulter and row unit settings, and hydraulics.

Fan speed too high

Check rpm on seed monitor.

Ground speed too high

Reduce ground speed.

Openers plugging

Check disk spacing and scrapers.

Seed hose disconnected or

leaking seed.

Reconnect or make repairs.

Meter door open on air cart

Clean seals and close door.

Check latches for proper operation.

Seed flow doesn’t stop

during turns

Height switch out of adjustment or

failed

Check lift switch engagement.