Set marker extension, Marker extension adjustment – Great Plains 2525P Assembly Instructions User Manual

Page 17

Test Marker Function

Great Plains Manufacturing, Inc.

17

2013-09-05

113-786M

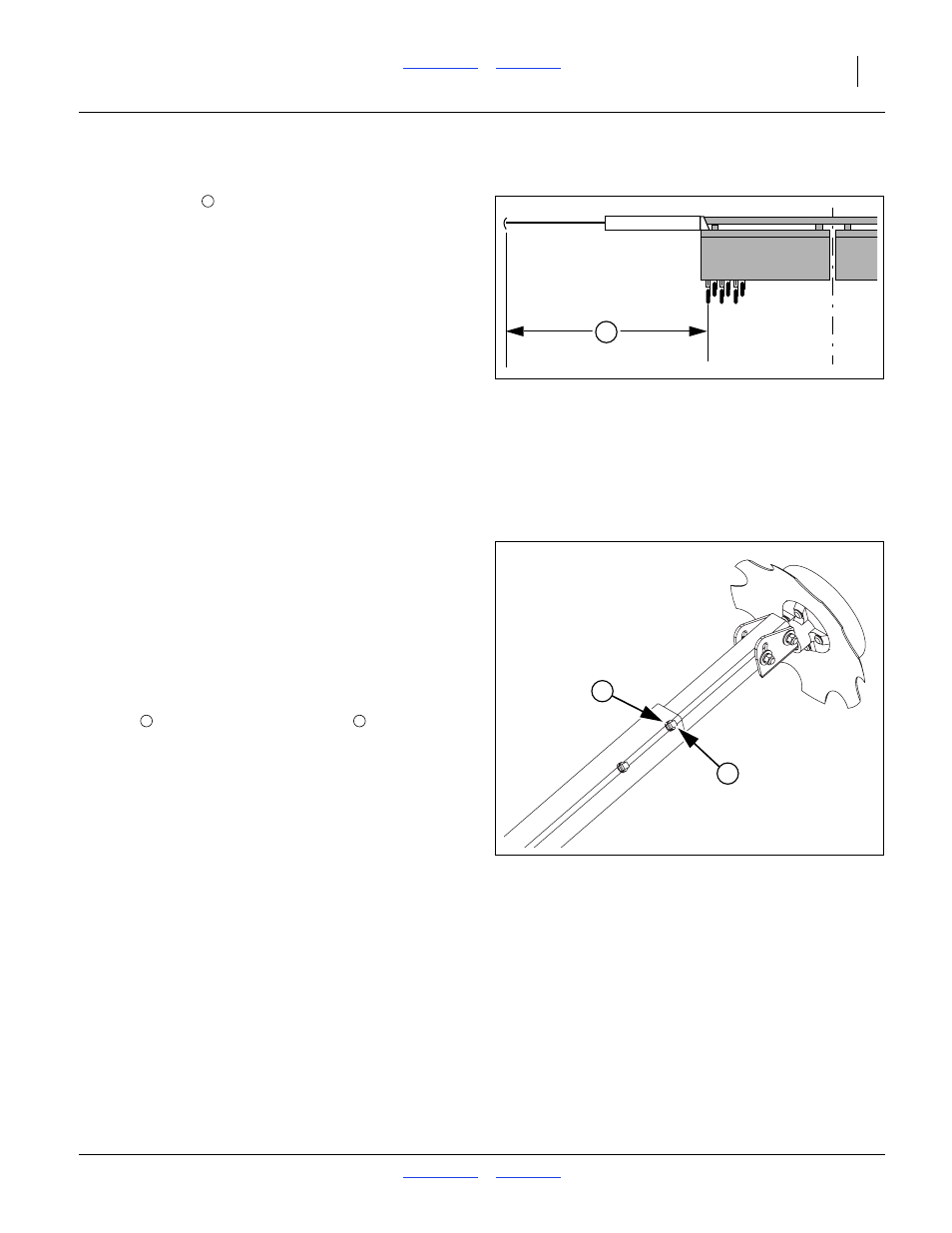

Set Marker Extension

Marker extension

dimensions vary with row spacing,

and row patterns (rows in use). Charts or tables are

provided in your Operator manual.

Marker extension is typically measured from the

centerline of the outside row (not the centerline of a twin-

row pair) to the mark left in the ground when the marker

is lowered.

If you modify your row spacing by shutting off rows, this

can also change the marker extension required. Some

changes can result in an asymmetric row spacing about

machine centerline. This usually causes the marker

extension to be different for left and right sides,

depending on the direction of planting for each

successive pass.

Making short practice passes confirms correct marker

extension.

Marker Extension Adjustment

To adjust a marker width or disk pivot orientation:

1.

Lower markers to field position and extend the

marker side to be adjusted.

2.

If disk angle or direction is to be changed, make that

change before adjusting extension.

3.

Pull forward to fully settle markers and leave a mark

to check.

4.

On telescoping outer marker tubes, loosen both jam

nuts

and both

1

⁄

2

inch set screws

5.

Move marker disk tube in or out to get the desired

mark placement.

6.

To change throw direction of marker, remove inner

tube completely, and reinsert at desired orientation.

7.

Tighten both

1

⁄

2

inch set screws and then both jam

nuts.

8.

Pull forward to check actual results and fold marker.

E

Figure 23

Marker Extension

E

Figure 24

Marker Extension Adjustment

19204

1

2

2