Bleed sequenced system, Re-connect cylinder rods – Great Plains 2525P Assembly Instructions User Manual

Page 13

Charge and Bleed

Great Plains Manufacturing, Inc.

13

2013-09-05

113-786M

Bleed Sequenced System

These instructions presume step 51 on page 12 has

been completed.

Refer to Figure 17

60. Set buckets or other oil collection containers under

both marker base ends. Loosen (“crack”) the NPT

connection at the elbow.

61. Slowly Extend the remote circuit for Markers. When

oil seepage is observed at the marker cylinder base

end connection, set the circuit to Neutral and secure

the hose at the NPT fitting.

Note: With a sequence valve, which marker side is

initially active is random, depending on the

internal state of the sequence valve.

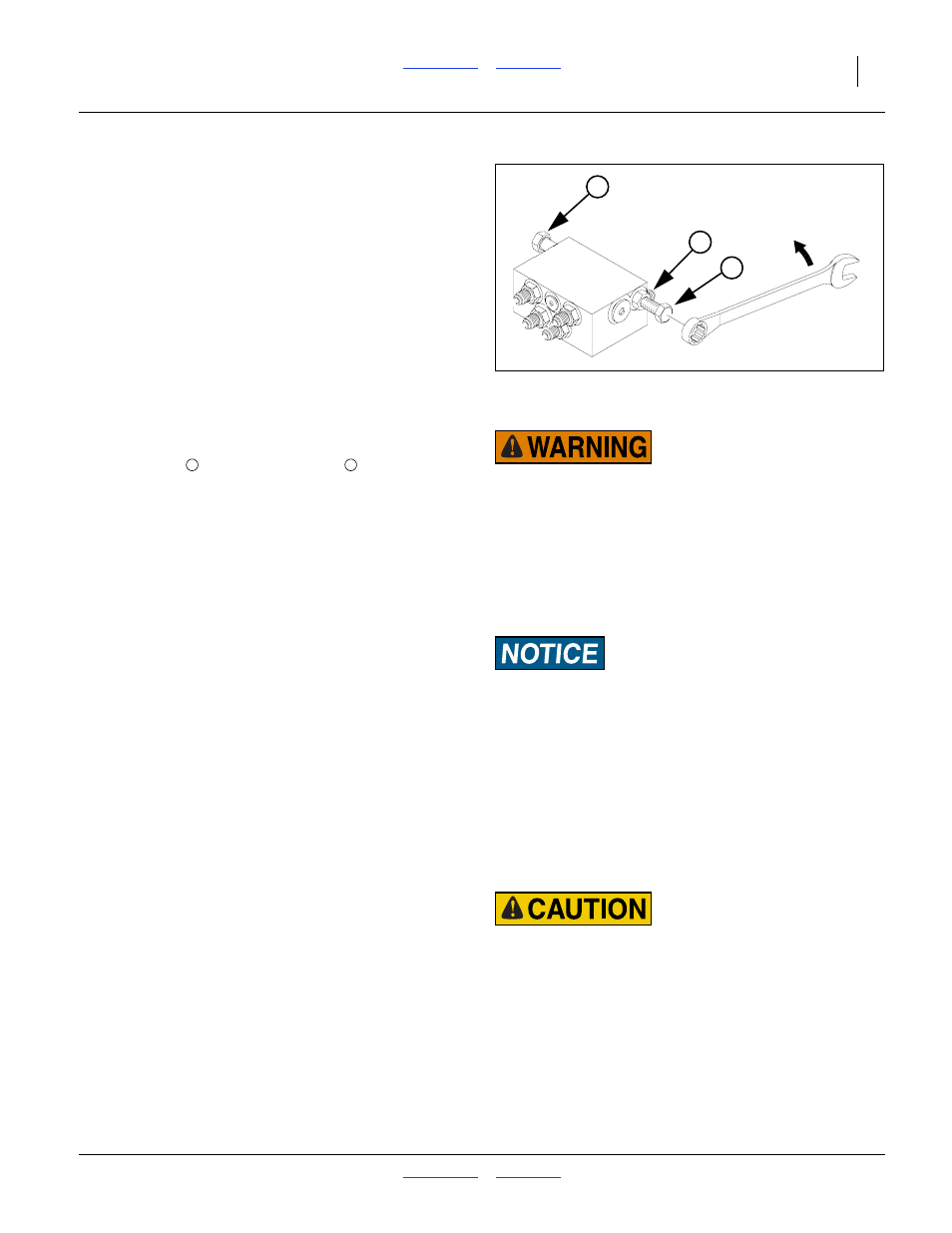

Note: If oil does not appear after a reasonable time,

increase flow at the sequence valve. Loosen both

jam nuts

. Turn both rate bolts

clockwise one turn to allow more flow.

62. Slowly Retract the circuit to extend the opposite side,

until oil appears at the cracked connection. Set the

circuit to Neutral. Secure the connection.

63. Slowly Extend the circuit to fully extend on rod. Set

circuit to Neutral.

64. Move the buckets to the rod ends. At the cylinder

with the extended rod, crack the NPT connection at

the rod end elbow.

65. Slowly Retract the circuit to supply oil to that rod end.

When seepage appears, set circuit to Neutral, and

secure connection.

66. Continue to Retract, to fully extend the other cylinder

rod. Set circuit to Neutral. Crack the rod end NPT

connection at that cylinder.

67. Slowly Extend the circuit to retract the extended rod.

When seepage appears, set circuit to Neutral and

secure fitting.

68. Extend and retract the circuit a few times, checking

for leaks.

Re-Connect Cylinder Rods

69. Use the hydraulic power source to extend a cylinder

rod so that the clevis pin holes are within the range

of the lug channel slots. Capture the clevis in the slot

with the saved pin. Secure with second washer and

cotter pin.

High Pressure Fluid Hazard:

System bleed requires intentional hydraulic leaks. Escaping

fluid under pressure can have sufficient pressure to penetrate

the skin causing serious injury. Use a piece of paper or

cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, seek immediate

medical attention from a physician familiar with this type of

injury.

Equipment Damage Risk:

Bleed only at JIC and NPT fittings.

Never try to bleed a QD (Quick Disconnect) fitting.

Avoid bleeding at ORB fittings. The O-ring is likely to be torn

if any pressure remains in the circuit.

Figure 18

Sequence Rate Adjust

14048

8

9

9

Pinch/Crush Hazard:

Step 69 requires extending cylinder rods while a second

worker guides the clevis into alignment with lug channel slots.

Keep hands out of the path of clevis motion.