Chain maintenance, Chain slack – Great Plains 800 Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

39

2011-10-25

175-057M

Chain Maintenance

Initially check the drive chains after the first 10 hours of

drill use. The slack of new chains tends to increase

during the first few hours of operation due to seating.

Thereafter, check the chains every 100 hours.

Lubricate chains any time there is a chance of moisture,

and when being stored at the end of the planting season.

Chain Slack

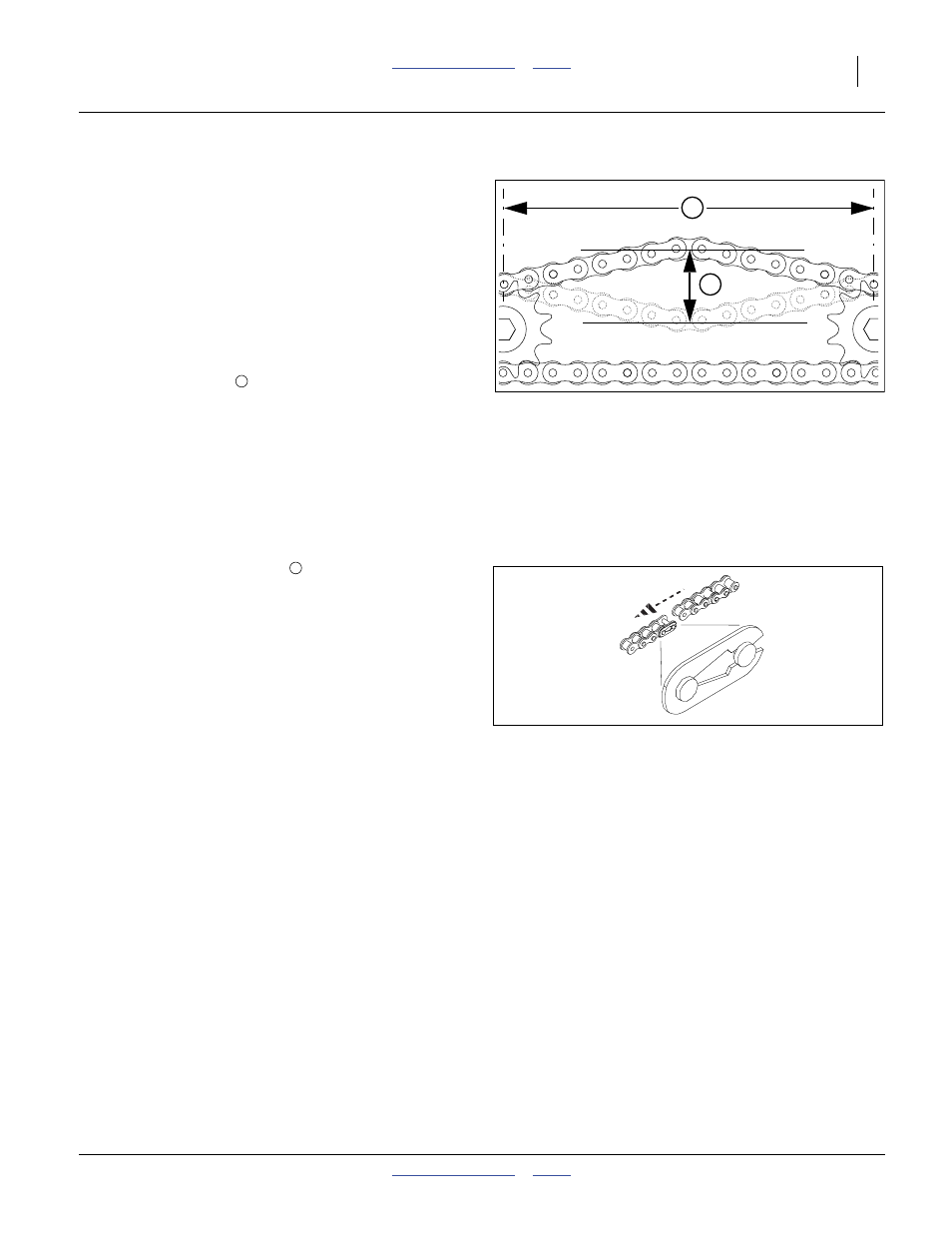

Refer to Figure 31, which, for clarity, greatly exaggerates

slack, and omits the idlers.

1.

Measure the span

for allowable slack:

Locate the longest span of each chain (usually the

span which does not run through the idlers).

2.

Determine the ideal slack:

Long chains (over 36 inches / 91 :

1

⁄

4

inch per foot (21 mm/m)

Vertical short chains:

1

⁄

4

inch per foot (21 mm/m)

Horizontal short chains:

1

⁄

2

inch per foot (42 mm/m).

3.

Measure the current slack

:

Acting at a right angle to the chain span at the centre

of the span, deflect the chain in both directions. The

slack is the distance of the movement.

4.

Adjust the idlers for ideal slack.

Whenever mounting a chain, make sure the clip at the

removable link is oriented to minimize snags.

Refer to Figure 32 (arrow shows chain direction)

Install clip with open end facing away from direction of

chain travel (shown by gray or striped arrows in chain

routing diagrams).

Figure 31

Measuring Chain Slack

27264

2

1

1

Figure 32

Chain Clip Orientation

26482

2