Bleeding hydraulics – Great Plains 800 Operator Manual User Manual

Page 41

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

37

2011-10-25

175-057M

Bleeding Hydraulics

To function properly, the hydraulics must be free of air. If

hydraulics have not been bled, they will operate with

jerky, uneven motions and could cause openers to drop

rapidly during raising and lowering. If hydraulics were not

bled during initial implement setup or if you replace a

part in hydraulic system during the life of the drill,

complete the following procedures.

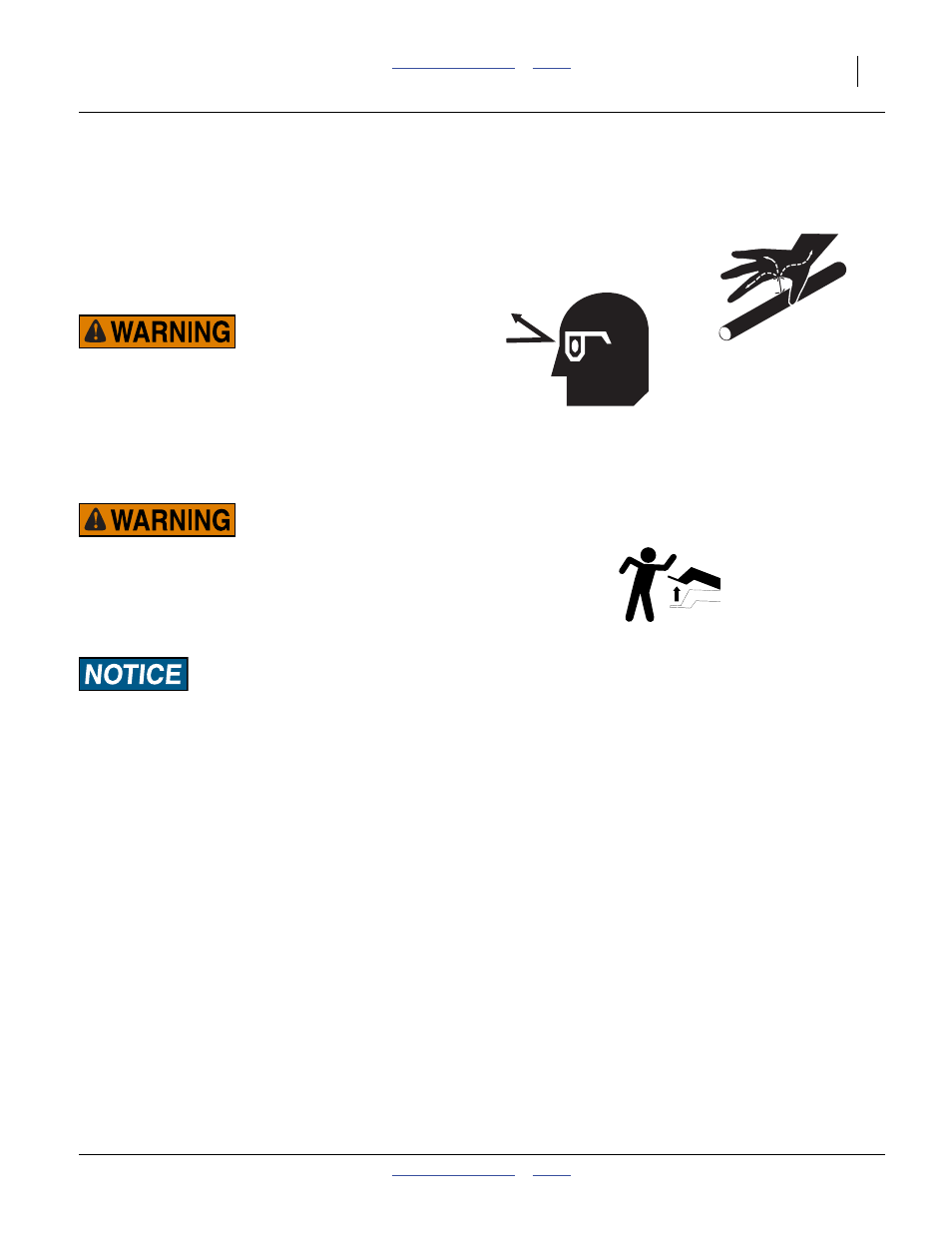

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

suspected leaks. Wear protective gloves and safety glasses or

goggles when working with hydraulic systems. Escaping fluid

under pressure can penetrate the skin causing serious injury.

If an accident occurs, seek immediate medical attention from

a physician familiar with this type of injury.

Negative Tongue Weight Hazard:

Be certain that drill is hitched securely to your tractor

drawbar and the safety chain is securely attached to tractor

before raising openers or unfolding drill. Raising openers on

unfolded, unhitched drill will cause drill tongue to rise

suddenly, which could cause serious injury or death.

Equipment Damage Risk:

Bleed at:

JIC (Joint Industry Conference, 37

° flare) or

NPT (National Pipe Thread, tapered thread) fittings.

Avoid bleeding at:

ORB (O-Ring Boss)

Never bleed at:

QD (Quick Disconnect) fittings.

Check hydraulic fluid level in tractor reservoir and fill to

proper level. Add fluid to system as needed.

System capacity for the Great Plains cylinder and hoses

is

1

⁄

2

gallon (1.9 liters).