Great Plains 800 Operator Manual User Manual

Page 39

Great Plains Manufacturing, Inc.

Troubleshooting

35

2011-10-25

175-057M

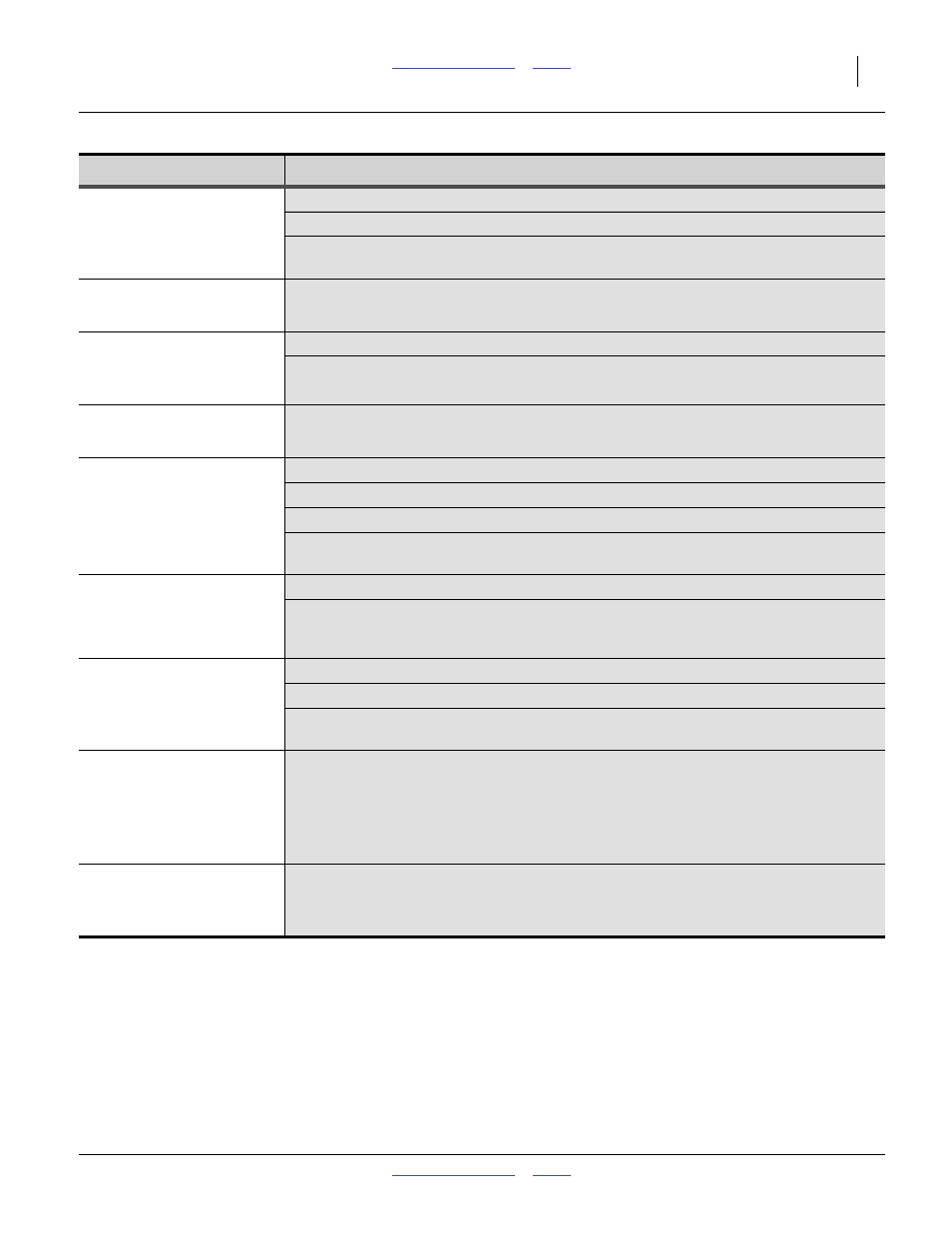

Uneven seeding depth

See “Opener Depth (Press Wheel Height)” on page 33.

See “Opener Frame Down-Force” on page 28.

Check that drill tongue matches tractor drawbar height. See “Hitch Preparation” on

page 12.

Chain-debris/retainer

clip

Be sure retainer clip is facing opposite way of chain travel.

Press wheel not

compacting the soil as

desired

Reset press-wheel depth. See “Opener Depth (Press Wheel Height)” on page 33.

Increase down pressure. See “Opener Frame Down-Force” on page 28.

Grain box not emptying

evenly

Certain models do not have the same number of seed cups between each bulkhead

divider. The compartment with more seed cups empties faster.

Press wheel or openers

plugging

Consider soil conditions. Drilling in damp or wet conditions can increase this problem.

Reduce down pressure. See “Opener Frame Down-Force” on page 28.

Do not back up or allow drill to roll backward with openers in ground.

Check Seed-Lok

®

wheels for mud accumulation. Lock up wheels if necessary.

Seed Firmer Lock-Up” on page 32.

Seed-cup sprockets

locked up or seed-drive

shaft twisted

Check for foreign material lodged in seed-cup sprockets.

Check for build-up of dried liquid insecticide in seed cups. Remove the build up by

disassembling each seed cup and scraping the foreign substance from the turning

surfaces.

Openers drill too deep

(Bulldozing)

If operating at high down-pressures, See “Opener Frame Down-Force” on page 28.

Reduce down pressure on openers. See “Opener Frame Down-Force” on page 28.

Check press-wheel adjustment. See “Opener Depth (Press Wheel Height)” on

page 33.

Openers raise when

tractor hydraulic lever

is held forward and

lower when lever is held

back

Reverse hydraulic hoses at tractor quick couplers.

Opener frames do not

float over uneven

terrain

Check that hydraulic circuit is in Neutral.

Problem

Solution