Great Plains 2N-3010 Operator Manual User Manual

Page 40

38

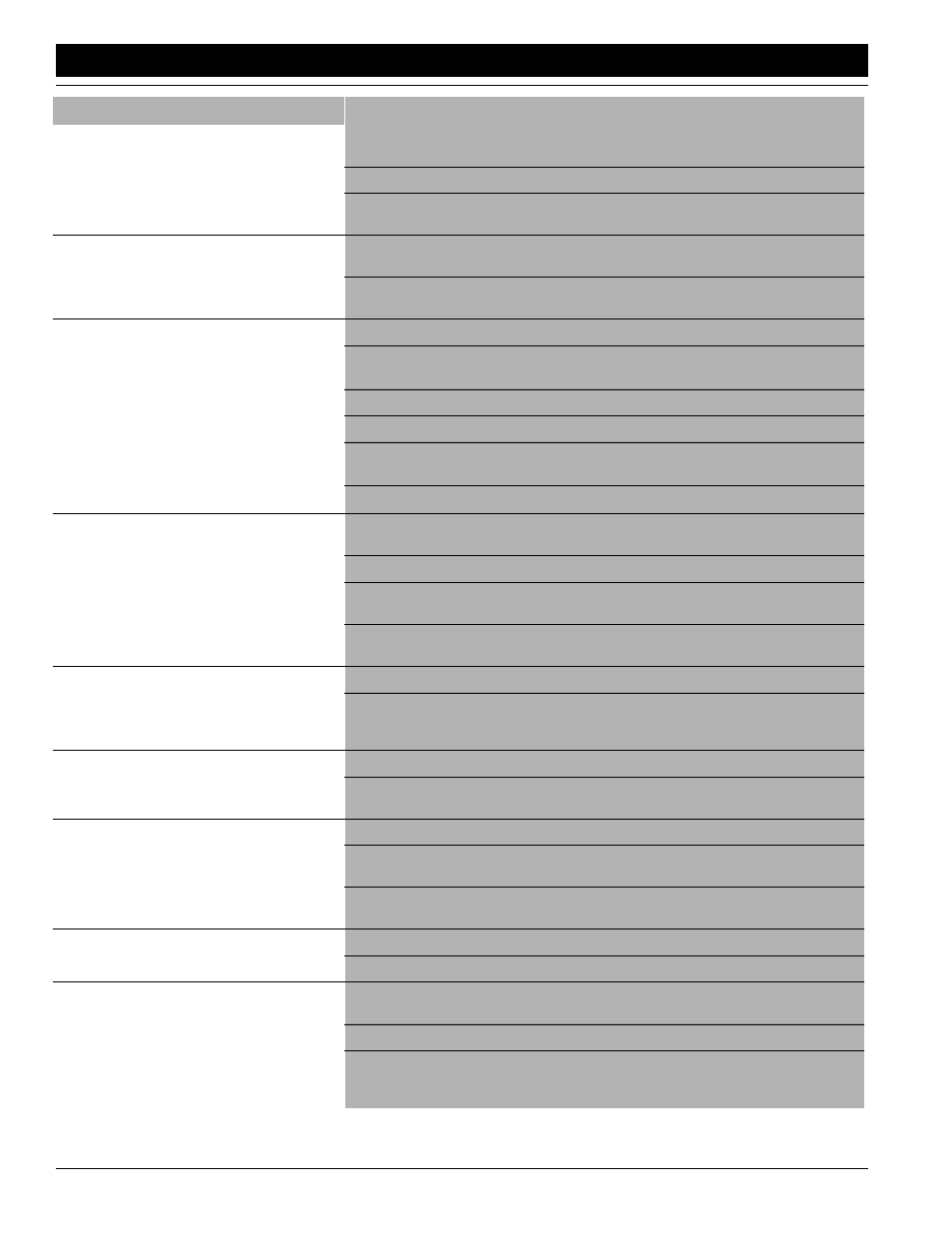

Section 4 Troubleshooting

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

12/27/05

Great Plains Mfg., Inc.

Press wheel not compacting

the soil as desired

Reset press-wheel depth. Refer to Press Wheel Adjustment, “Adjustments,”

page 22.

Re-adjust press wheel depth to match coulter depth.

Increase down-pressure on disk openers. Refer to Opener Down-Pressure

Adjustment, “Adjustments,” page 22.

Grain box not emptying evenly

Check that speed-change gearbox and seed-rate handles are set the same

on each drill box.

Certain models do not have the same number of seed cups between each

divider of bulkhead. The section with more cups will empty sooner.

Press wheel or openers plugging

Check soil conditions–may be too damp.

Decrease opener down pressure. See Opener Down-Pressure Adjustment,

“Adjustments,” page 22.

Do not back up with openers in the ground.

Do not stop and allow drill to roll backward with openers in ground.

Check optional Seed-Lok wheels. Remove if soil conditions are too wet.

Refer to Seed-Lok, “Adjustments,” page 36.

Install coulter trash tines. Refer to Coulter Tines, “Adjustments,” page 30.

Raising and lowering drill is rough or

uneven.

Lubricate wheel-arm pivot casting. Refer to Lubrication, “Maintenance and

Lubrication,” page 41.

Check hydraulic fittings for leaks.

Rephase the field-lift cylinders. Refer to Lifting the Drill in the Field, “Operat-

ing Instructions,” page 17.

Check that rephasing cylinders have been properly bleed. Refer to Bleed

Field-Lift Hydraulics, “Drill Preparation and Setup,” page 11.

Seed-cup sprockets locked up or twisted

seed-cup shaft

Check for foreign material lodged in one or more seed-cup sprockets.

Inspect seed-cups for dried liquid insecticide. Remove build-up by disas-

sembling each seed cup and scraping the foreign substance from the turn-

ing surfaces.

Coulters not going deep enough

Check weight charts on page 21 and add weight if necessary.

Change depth stop to lower coulters. Refer to Coulter Adjustments, “Adjust-

ments,” page 19.

Coulters and drill going too deep

Check weight charts on page 21 and remove weight if necessary.

Set press wheels to a shallower depth. Refer to Press Wheel Adjustment,

“Adjustment,” page 22.

Change depth stop to raise coulters. Refer to Coulter Adjustments, “Adjust-

ments,” page 19.

Openers and/or coulters plugging in

adverse conditions

Drill at a slight angle to the rows.

Install coulter trash tines. Refer Coulter Tines, “Adjustments” page 30.

Actual seeding rate is different than

desired

Check tire pressure. Proper inflation is listed on Tire Inflation Chart,

“Appendix,” page 50.

Check gauge wheel size. Proper size is 11L x 15" 8-ply.

Seed treatment will affect seeding rate if the chemicals build up in seed cup.

Unless cleaned regularly, this build-up can cause the seed-cup shaft to twist

or break.

Problem

Solution