Coulter tines, Harrow attachment adjustment, Seed-lok – Great Plains 2N-3010 Operator Manual User Manual

Page 38

36

Section 3 Adjustments

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

12/27/05

Great Plains Mfg., Inc.

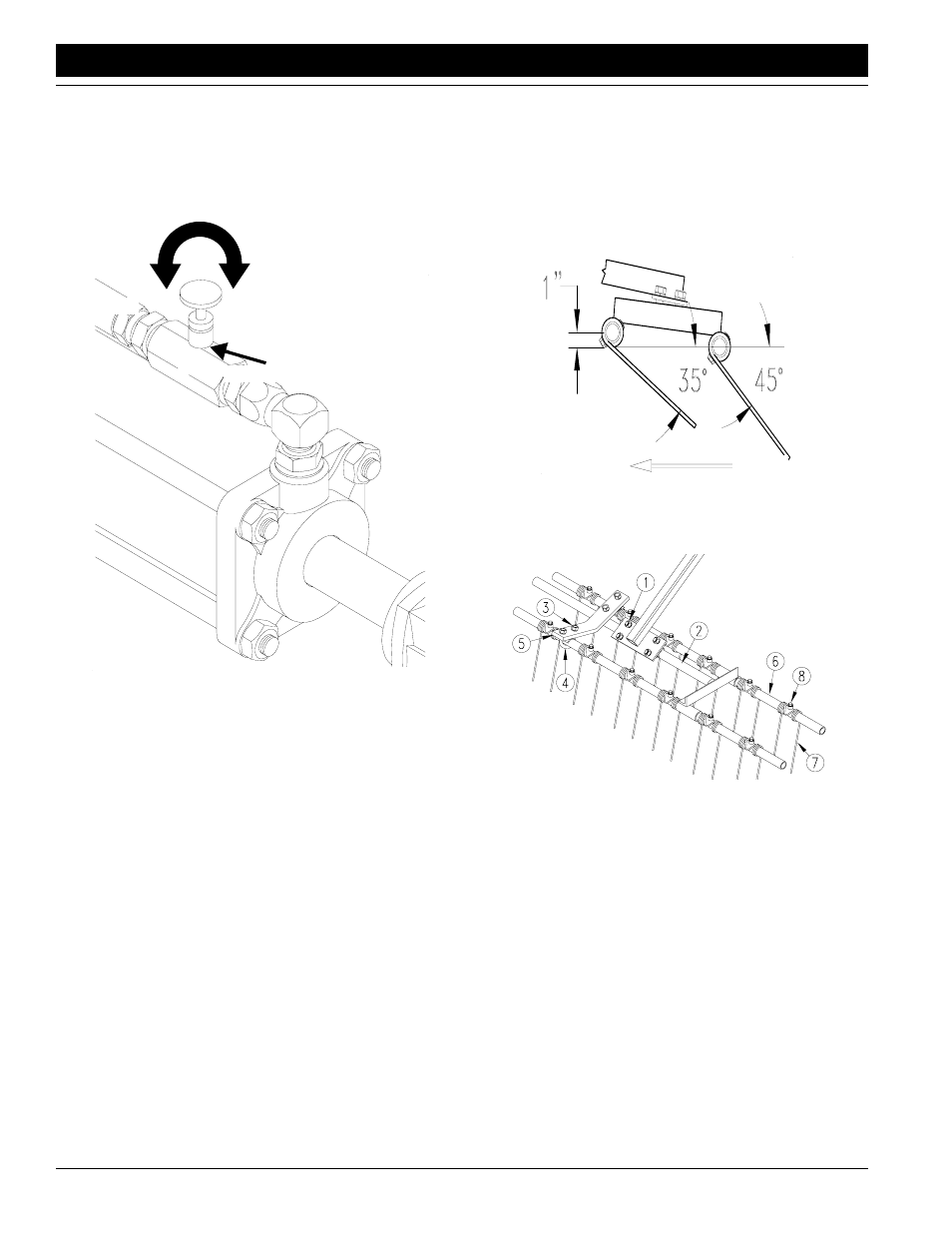

The single-marker system is equipped with a needle valve

in the hydraulic hose line at the rod end of the marker cyl-

inder as shown in Figure 3-18. Turn the adjustment knob

clockwise to decrease or counterclockwise to increase

folding speed. Adjust to a safe speed. Excessive folding

speed could damage the marker and may void the warran-

ty.

Figure 3-18

Speed Adjustment, Single Marker

Coulter Tines

Optional coulter tines are available for the front-mounted

coulters. In high-residue fields, the tines will help guide

residue under the coulters and openers to prevent plug-

ging. Under normal conditions these tines should not be

needed. Remove or install the tines as field condition war-

rant.

Harrow Attachment Adjustment

Figure 3-19 shows a successful harrow position for no-till

conditions. Because of different soil moisture, trash levels

and trash types, you may need to reposition the tube

frame or tines. Initially position the frame and tines as

shown in Figure 3-19, then re-adjust as necessary.

15625

Needle Valve

Slower

Faster

To adjust the frame, refer to Figure 3-20. Loosen the four

hex nuts (1) on the u-bolts and rotate the frame tube (2) as

necessary.

To adjust the tines, refer to Figure 3-20. Loosen the four

1/2-inch hex nuts (3) on the 1/2-inch u-bolts (4) on the sup-

port bar (5). Rotate tine tubes (6) so the tines (7) are

against the stop bushings (8) and are angled back as nec-

essary. Retighten hex nuts on u-bolts.

Figure 3-20

Harrow Adjustment

Seed-Lok

The optional Seed-Lok firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and do

not require adjusting. In some wet and sticky conditions

the wheels may accumulate soil. Remove or install the

wheels as field conditions warrant.

12667

Figure 3-19

Tine Angle For No-Till Drilling

16297