Section 3 adjustments, No-till seeding coulter adjustments, Hydraulic depth control – Great Plains 2N-3010 Operator Manual User Manual

Page 21: No-till seeding, Coulter adjustments

19

Section 3 Adjustments

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

Great Plains Mfg., Inc.

Section 3

Adjustments

No-Till Seeding

To get full performance from your no-till drill, you need a

good understanding of coulter, opener and press wheel

operation.

Coulters. A no-till coulter is mounted independently and

directly ahead of each opener. The coulters cut through

heavy trash and make a groove in the soil. The coulters

are mounted directly on the box frame. Consequently, the

cutting depth of all coulters changes as the drill is raised

and lowered. The cutting depth of the coulters is controlled

by an adjustable hydraulic depth stop. Coulters that run di-

rectly in tire tracks can be lowered individually. Refer to

Coulter Adjustments, this page, for information on how to

make these adjustments.

Openers. Each opener is mounted on the drill with parallel

arms. This parallel-action mounting allows the opener to

move up and down while staying in-line with a coulter.

Opener double disks widen the coulter groove, making a

seed bed. A seed tube mounted between the disks deliv-

ers seed to the trench.The down force needed to cut and

widen the coulter groove is supplied by two springs nested

in the parallel linkage. Adjusting these springs changes

opener down-force. Refer to Opener Down-Pressure Ad-

justment, page 22, for information on how to make this ad-

justment.

Press Wheels. Attached to the rear of each opener is one

of several press-wheel options. The press wheels provide

two important functions.

First, the press wheels close the furrow, gently pressing

the soil over the seed. To provide consistent seed firming,

the press wheels are free to move downward from their

normal operating position. This system maintains press-

ing action even if the opener arm is lifted when the disks

encounter obstructions.

Second, the press wheels provide opener depth control.

The higher the press wheels run relative to the double

disks, the deeper seed will be placed. To maintain a con-

sistent depth, upward press-wheel movement is restricted

by an independently adjustable stop on each opener. Re-

fer to Press Wheel Adjustment, page 22, for information on

how to make this adjustment.

Coulter Adjustments

The drill is assembled so that when the coulters are at two

inches deep, the seeding depth is about one inch. This is

a good baseline setting for most seeding operations. As

field conditions warrant, you can change settings on the

entire drill or individual coulters.

Hydraulic Depth Control

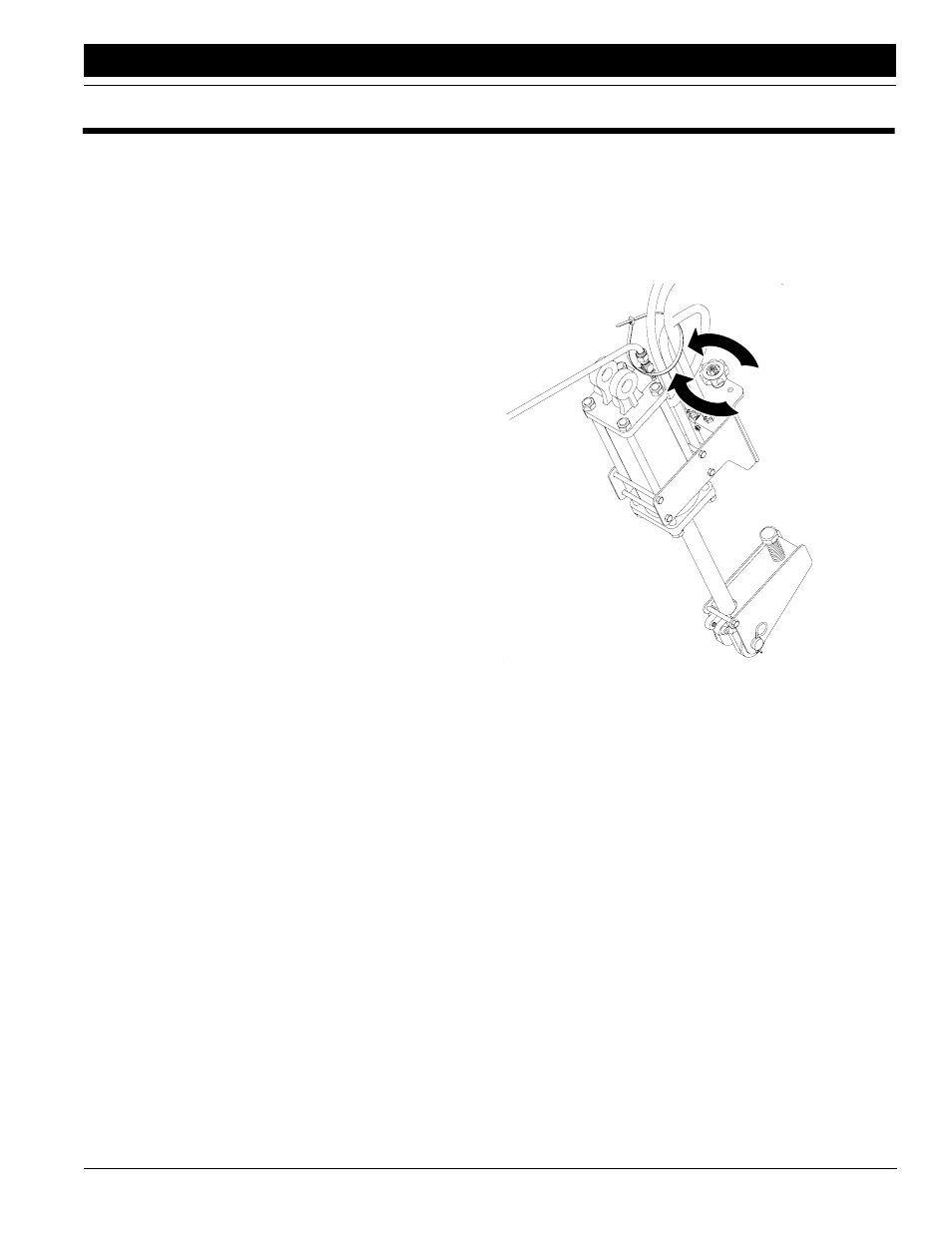

The master field-lift cylinder on the left transport wheel is

equipped with a hydraulic valve that regulates coulter

depth. Figure 3-1 shows the valve and knob used to adjust

coulter depth.

Turn the knob clockwise to lower the coulters. Each clock-

wise rotation will lower the coulters about 3/32 inches.

Make depth adjustments with the implement slightly

raised. After adjusting the valve, raise and lower the imple-

ment several times and recheck coulter depth.

The depth stop regulates depth on all coulters. If the ends

of either box run higher or lower than the center, the field-

lift system may be out of phase or have air in it, or the

frame sections may not be level. Refer to Lifting the Drill in

the Field, “Operating Instructions,” page 17, Bleed Field-

Lift Hydraulics, “Drill Preparation and Setup,” page 11, or

Leveling Adjustment, page 34.

Figure 3-1

Left Transport-Wheel Cylinder with Depth-Control Stop

Raise Coulters

Lower Coulters

16271