Opener down-pressure adjustment, Press wheel adjustment, Setting the seeding rate – Great Plains 2N-3010 Operator Manual User Manual

Page 24

22

Section 3 Adjustments

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

12/27/05

Great Plains Mfg., Inc.

Opener Down-Pressure Adjustment

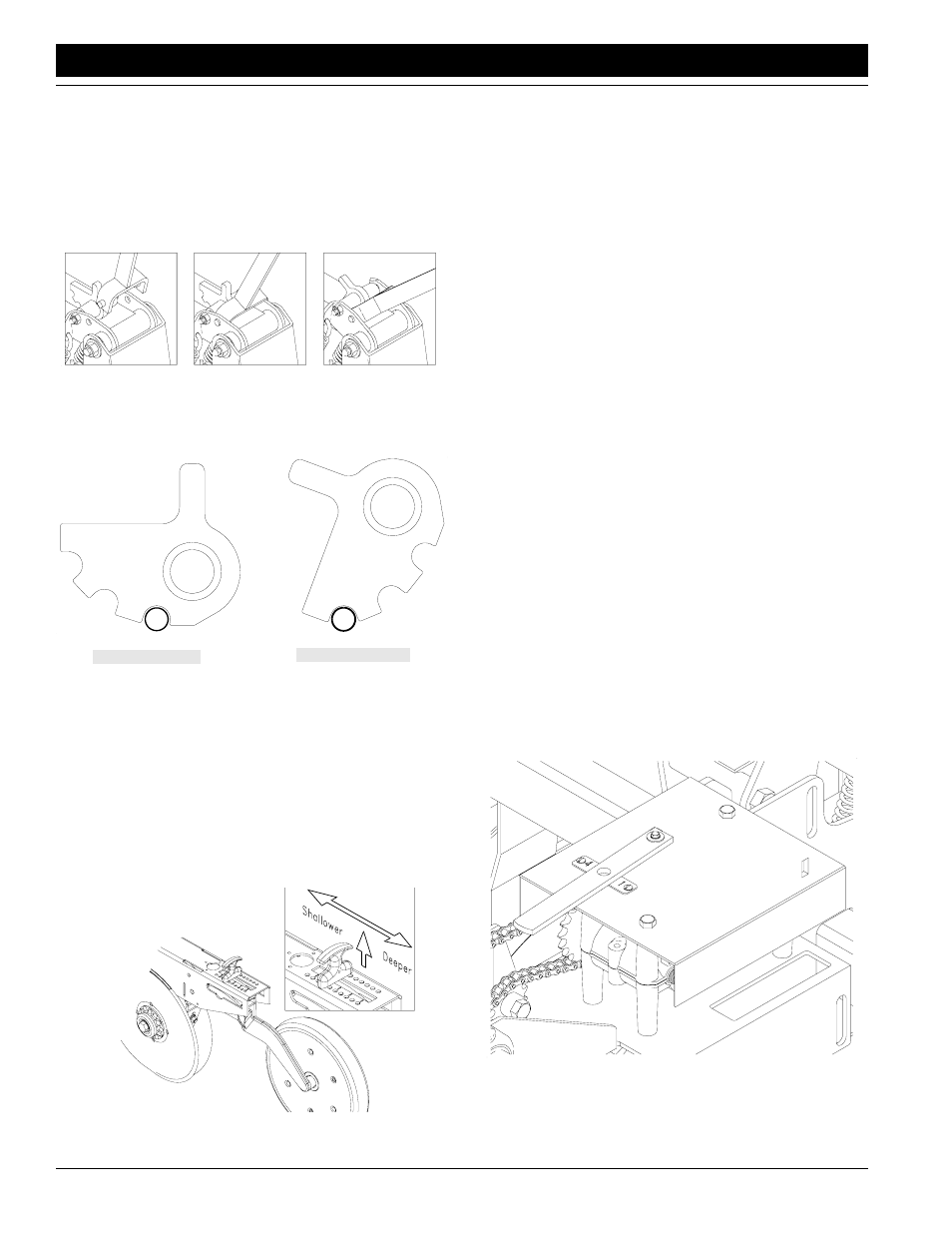

You can adjust spring down pressure individually for each

opener. This is useful for penetrating hard soil and plant-

ing in tire tracks.

To adjust down pressure, use the adjustment tool stored

under the walkboard. Position the tool in the holes on the

spring mounting plates and pull down on the adjuster as

shown Figure 3-6.

Figure 3-6

Opener-Spring Adjustment

Minimum and maximum settings are indicated by the po-

sition of spring adjuster as shown in Figure 3-7.

Figure 3-7

Spring Settings

Press Wheel Adjustment

Changing the height of the press wheel automatically

changes seeding depth. To adjust, lift up on the T-handle

and slide it forward or back as shown in Figure 3-8.

•

For shallower seeding, slide the handle toward the im-

plement.

•

For deeper seeding, slide the handle away from the im-

plement.

Figure 3-8

Press Wheel Adjustment

12105

Minimum Force

12104

Maximum Force

12100

Setting the Seeding Rate

Calibrating the seeding rate requires four steps: shifting

the speed-change gearbox, adjusting the seed-rate han-

dle, setting the seed-cup doors, and checking the seeding

rate.

Check the seed-rate charts starting on page 24 or in the

drill boxes. These charts list the proper settings for the

speed-change gearbox and seed-rate handle for various

seeds and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The rates are based

on 11L x 15 8-ply rib implement tires and 265/70B16 skid

steer tires. Many factors will affect seeding rates including

foreign material, seed treatment, seed size, field condi-

tions, tire pressure and test weight. Minor adjustments

likely will be needed. Set and check the seeding rate using

the procedures below, then re-adjust the rate as neces-

sary.

Before setting the seeding rate, rotate both gauge wheels

to see that the seed cups and drive are working properly

and free from foreign material.

NOTE: Each drill box has its own metering mechanism.

After adjusting and checking the rate on one box, set the

same rate on the other box.

1.

Shift Speed-Change Gearbox

The speed-change gearbox, Figure 3-9, is designed

to give you a variety of speeds for different seeds and

seeding rates. You can shift between four different

drive types.

Refer to the seed-rate charts for the correct drive

type–1, 2, 3 or 4. Move the selector handle on the

gearbox until the correct number appears in the han-

dle window as shown in Figure 3-9. Rotate the tires a

few turns to confirm the gearbox has engaged.

Figure 3-9

Speed-Change Gearbox

12916