Tightening o-ring fittings – Wheatheart Self-Propelled Auger Kit (Wheatheart R Series) User Manual

Page 46

8. A

PPENDIX

W

HEATHEART

- S

ELF

-P

ROPELLED

A

UGER

K

IT

8.2. T

IGHTENING

O-R

ING

F

ITTINGS

W

HEATHEART

BH & R S

ERIES

46

30761 R0

Torque figures indicated above are valid for non-greased or non-oiled threads

and head unless otherwise specified. Therefore, do not grease or oil bolts or

capscrews unless otherwise specified in this manual. When using locking

elements, increase torque values by 5%.

8.2. TIGHTENING O-RING FITTINGS

1. Inspect o-ring and seat for dirt or obvious defects.

2. On the angle fittings, back the lock nut off until washer bottoms out at top of

groove.

3. Hand-tighten fitting until back up washer or washer face (if straight fitting)

bottoms on face and o-ring is seated.

4. Position angle fittings by unscrewing no more than one turn.

5. Tighten straight fittings to torque shown.

6. Tighten while holding body of fitting with a wrench.

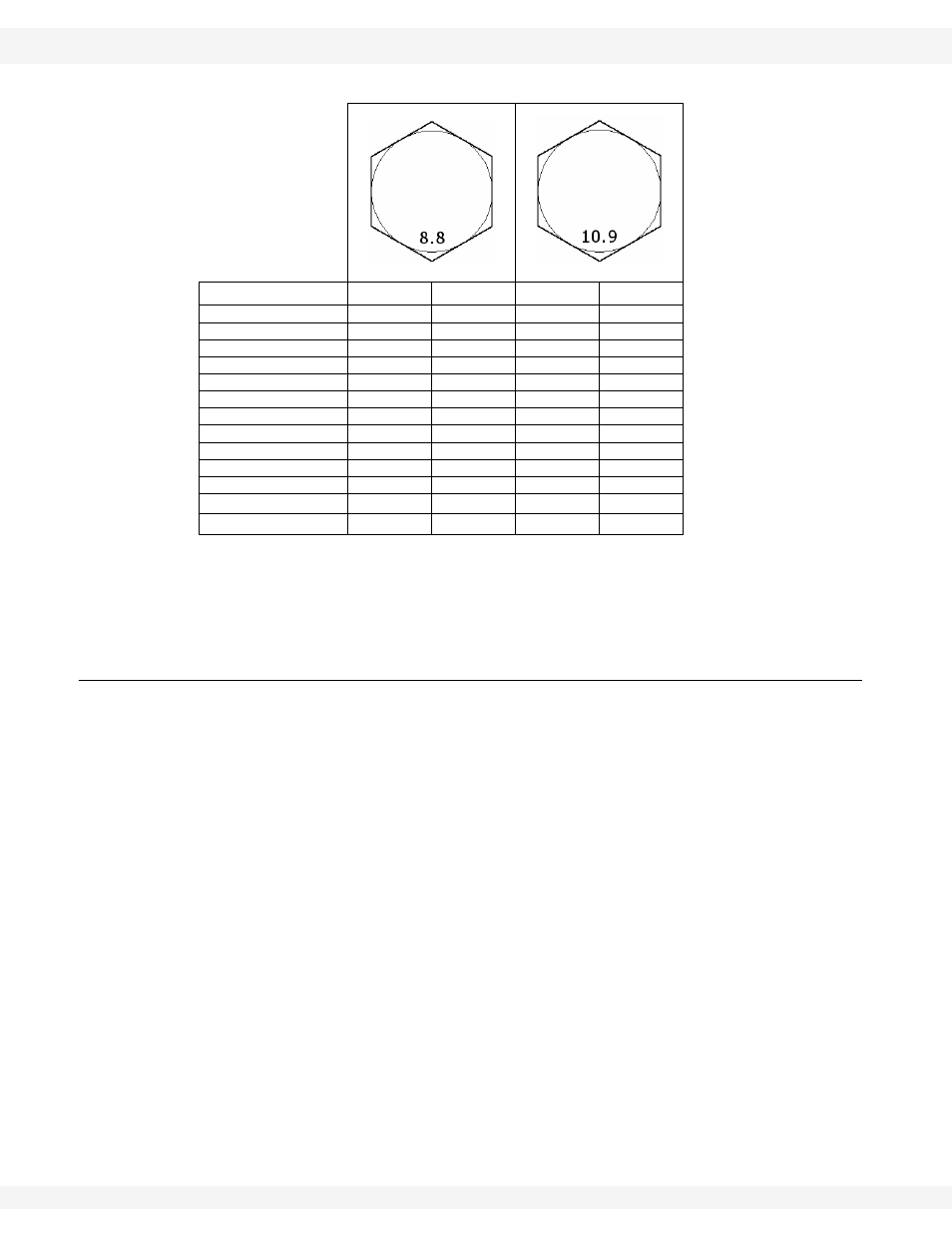

Table 8.2 Metric Bolt Torque

BOLT DIAMETER

(Nm)

(lb-ft)

(Nm)

(lb-ft)

M3

0.5

0.4

1.8

1.3

M4

3

2.2

4.5

3.3

M5

6

4

9

7

M6

10

7

15

11

M8

25

18

35

26

M10

50

37

70

52

M12

90

66

125

92

M14

140

103

200

148

M16

225

166

310

229

M20

435

321

610

450

M24

750

553

1050

774

M30

1495

1103

2100

1550

M36

2600

1917

3675

2710