Maintenance & storage, General maintenance procedures – Wheatheart WHR 130 x 51-71ft Augers PTO User Manual

Page 43

WHEATHEART - GHR & WHR GRAIN AUGERS

6. M

AINTENANCE

& S

TORAGE

GRAIN AUGERS SD

6.1. G

ENERAL

M

AINTENANCE

P

ROCEDURES

30662 R1

43

6. Maintenance & Storage

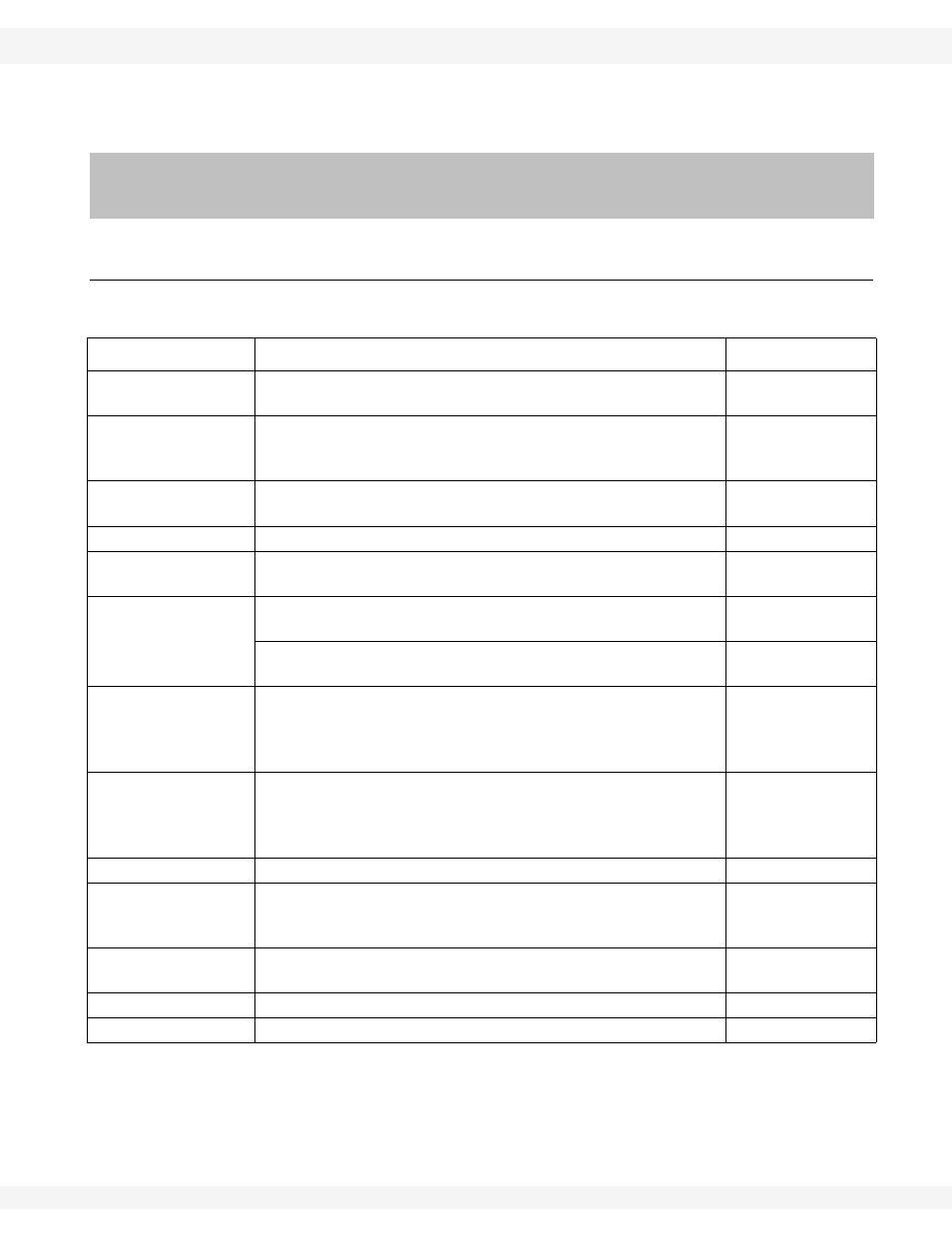

6.1. GENERAL MAINTENANCE PROCEDURES

Please follow the guidelines below.

Warning: Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

Area

Maintenance

Frequency

General

While auger is in use, observe the operation checklist in

Operation section.

Daily

General

Check all operating, lifting, and transport components.

Replace damaged or worn parts before using auger.

For replacement instructions, see Assembly section.

Regularly

Lift Cable

Check and replace if frayed or damaged. Make sure cable

clamps are secure.

Periodically

Wheel Hubs

Repack with lithium-based grease.

Every 2–3 years

Tire Pressure

Check with a pressure gauge. Pressure should be main-

tained according to side wall recommendations.

Monthly, or if it

seems low

PTO Driveline

Lubricate both universal joints.

After every 8 hrs

of operation

Lubricate the center portion of the driveline (grease fitting is

beneath shield) on a yearly basis.

Yearly

Upper chain drive

Fill enclosed upper drive housing to plug level with grease.

2200 g (78 oz)

For continuous use in extreme cold, semi-fluid arctic

grease or heavy oil may be used

Regularly

Drive Chain Adjust-

ment

Maintain 1/4” - 1/2” (0.64 cm - 1.27 cm) chain deflection.

To adjust, loosen bolts on top bearing in the upper drive

housing, adjust hcian to proper tension, and re-tighten

bolts

Regularly

Intake Bushing

Lubricate.

Daily

Gearbox

Maintain oil level at half full (center of cross shaft)

Gearbox should be level if checking or refilling, do not

overfill

Regularly

Hydraulic Hose

Using cardboard as a backdrop, check hose and coupler for

leaks, wear, or damage. Replace if necessary.

Frequently

Cable Sheaves

Oil sheave pins on lift cylinder.

Twice a year

Truss Cables

Adjust to keep auger tube reasonably straight.

As necessary