Caution – Wheatheart WHR 130 x 51-71ft Augers PTO User Manual

Page 30

3. A

SSEMBLY

WHEATHEART - GHR & WHR GRAIN AUGERS

3.10. L

IFT

C

YLINDERS

& C

ABLE

GRAIN AUGERS SD

30

30662 R1

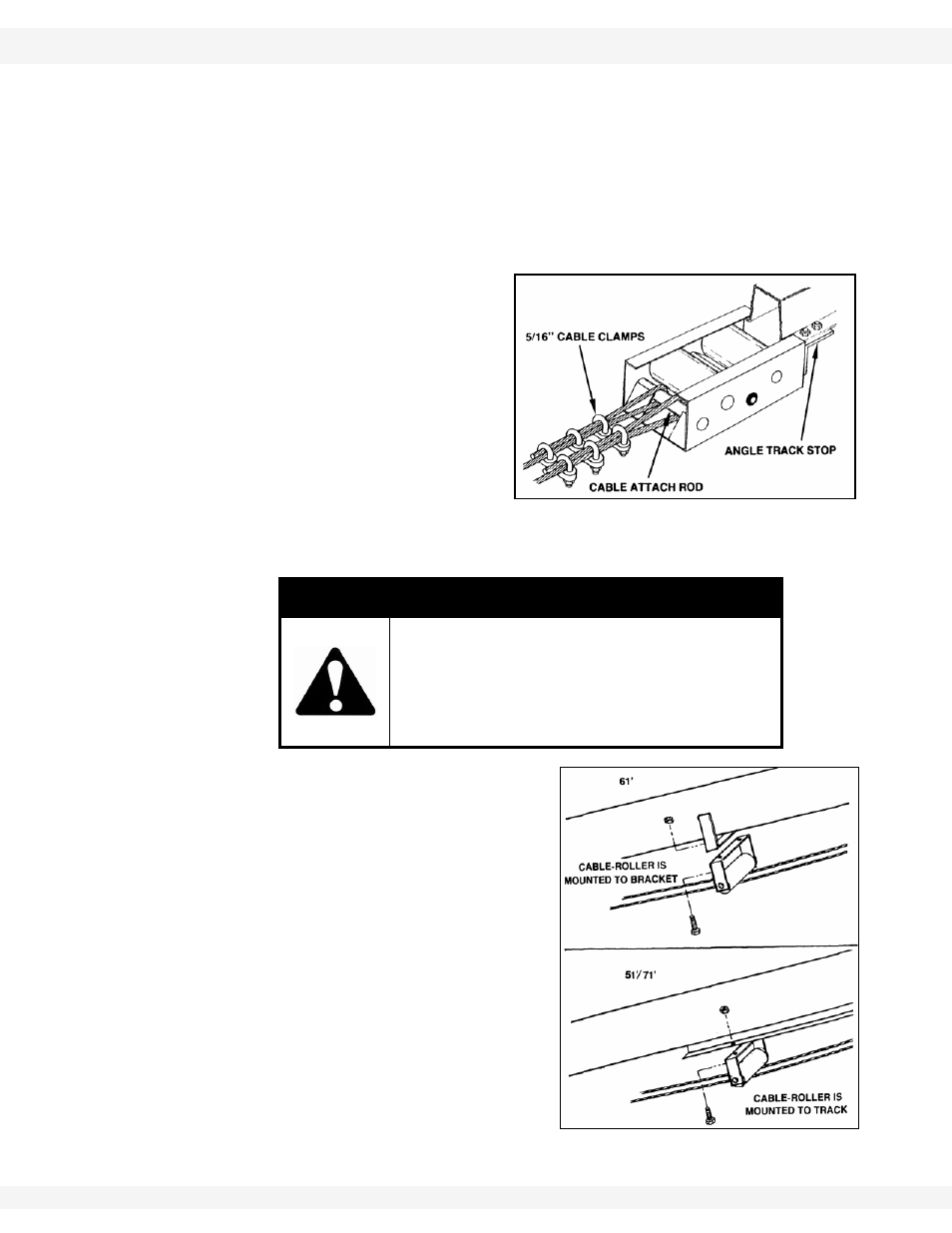

3. Secure the solid connector end of the short cylinder connector hydraulic hose

to above elbow fitting on right side lift cylinder. Use thread sealant (not

supplied). The other end of this short hose is secured later.

4. Attach other lift cylinder to left side of welded bracket with four 7/16” x 1-1/4”

bolts and locknuts. Tighten securely (see Figure 3.11 for correct position).

Note:

Although the lift cables are factory installed on the lift cylinders, make certain the

cable clamps at the cylinder are secure and the cables are properly seated in the

cable sheaves before attaching the cable to the track shoe.

5. With

both

cylinders in full down

position and track shoe resting

against the track stop, thread

both cables over the cable

attach rod on the track shoe.

Pull cable very tight then secure

with three 5/16” cable clamps

on each cable, positioned as

shown in Figure 3.19. Tighten

securely. Tie up excess ends of

lift cable with tape or ty-wrap.

Lift cables will stretch with use.

Check frequently and adjust when necessary.

6. Attach

the

cable roller to the

appropriate location with two 7/16” x

1-1/4” bolts and locknuts (Figure 3.20).

• On the 61' auger, attach the cable

roller to bracket located between

lower end of track and lift cylinder

(see Figure 3.11 for location).

• On the 51'/71' augers, attach the

cable roller to lower end of track

(see Figure 3.11 for location).

CAUTION

Track shoe must rest against the track stop

when adjusting cable.

Failure to heed will allow auger to raise higher

than it is designed to lift, resulting in damage

to auger and injury to personnel.

Figure 3.19

Important:

Figure 3.20