Hydraulic power swing (option), Notice – Wheatheart X13 Power Swing User Manual

Page 17

W

HEATHEART

- P

OWER

S

WING

M

ANUAL

2. A

SSEMBLY

E

LECTRIC

AND

H

YDRAULIC

2.5. H

YDRAULIC

P

OWER

S

WING

(O

PTION

)

30802 R0

17

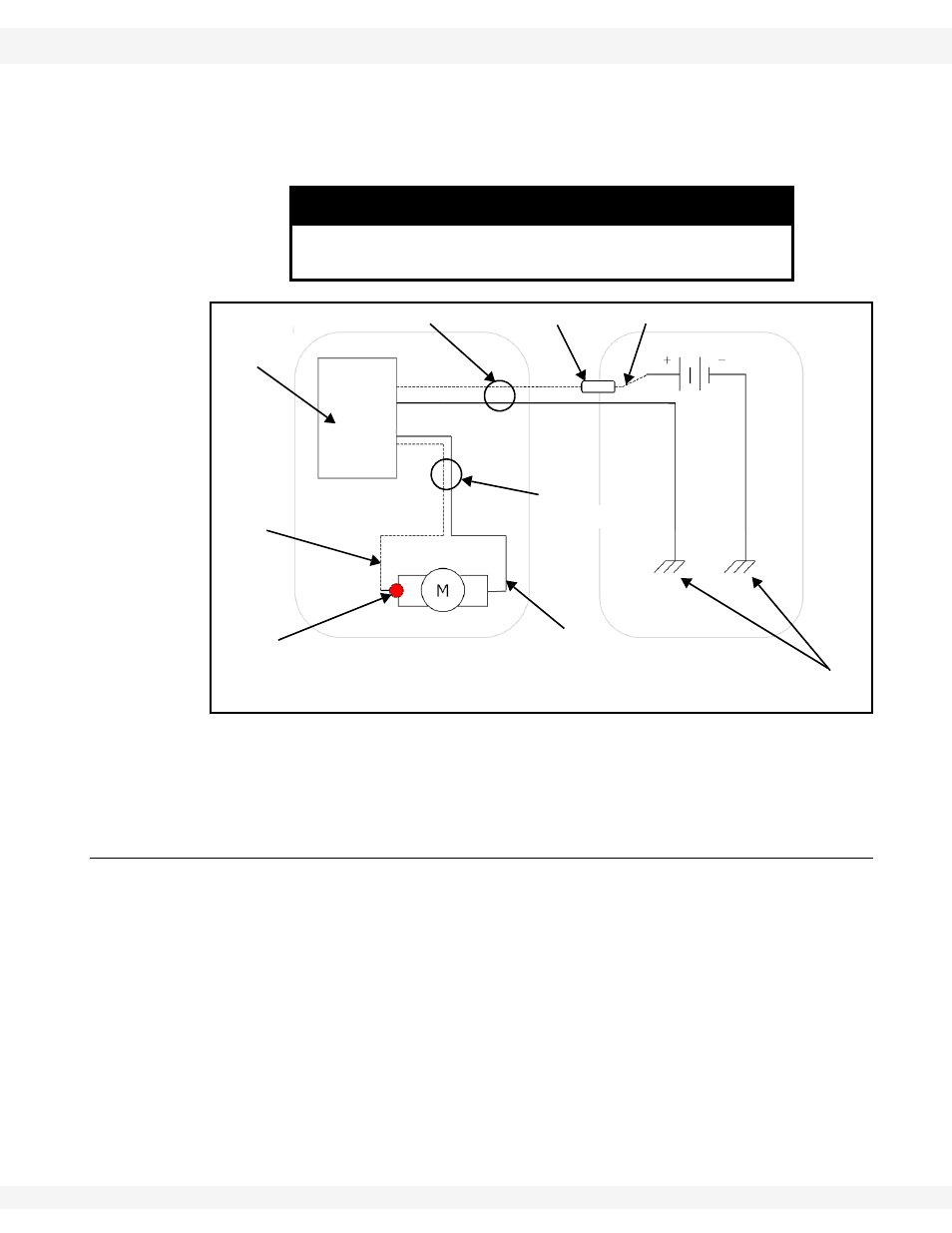

9. Attach the positive wire directly to the positive terminal on the tractor battery

and the negative wire to the tractor chassis as shown in Figure 2.10. The

negative terminal on the tractor battery should also be grounded to the

chassis. There are 5/16” lugged terminals supplied with the kit.

Figure 2.10 Power Swing Wiring Diagram

Note:

If the electric power swing will need to be moved from one tractor to another on a

regular basis, 200 Amp booster-style cable clamps can be installed at the

owner’s own risk and expense.

2.5. HYDRAULIC POWER SWING (OPTION)

1. Install the hydraulic control valve and top clamp assembly onto the swing

tube using a bottom 13” half-clamp and two 7/16” x 1-1/4” bolts (18698) and

locknuts (19598). This is to be installed approximately 24” up the swing tube,

from the top of the Power Swing clamp (see Figure 2.11).

2. Attach the two short 1/2” hydraulic hoses to the valve and the hydraulic motor

on the Power Swing (see Figure 2.11).

3. Install a half-clamp hose/wire retainer further up the swing tube, using two

7/16” x 1” bolts (19542) and locknuts (19598). Position half-clamp retainer in

best location, and tighten securely. See Figure 2.11.

4. Attach long 1/2” hydraulic hoses to the hydraulic valve.

5. Route these hoses towards tractor, through the clips on top of the half-clamp

retainer, and loop them around the spout head on the swing auger.

NOTICE

If these electrical cables are not hooked up properly the

electric controller will be damaged.

TRACTOR

POWER SWING

LONG ELECTRICAL CABLE

POSITIVE

WIRE

NEGATIVE WIRE AND TERMINAL

GROUNDED TO CHASSIS

POSITIVE WIRE

NEGATIVE

WIRE

RED

BOOT

RECEIVER

BOX

CIRCUIT BREAKER

SHORT

ELECTRICAL

CABLE