Irving oil – Vermont Casting IRFSDV24 User Manual

Page 5

5

Irving Oil

10004000

Max. Max.

Input Input

Model

Fuel

Gas Control

BTU/h BTU/h

IRFSDV24RN

Nat

Millivolt Hi/Lo

20,000 14,000

IRFSDV24RP

Prop

Millivolt Hi/Lo

20,000 15,000

IRFSDV34RFN

Nat

Radio Frequency 30,000 21,000

IRFSDV34RFP

Prop

Radio Frequency 30,000 22,500

Natural

LP (Propane)

Input Minimum

5.5” wc

11” wc

Input Maximum

14” wc

13” wc

Manifold Pressure

3.5” wc

10” wc

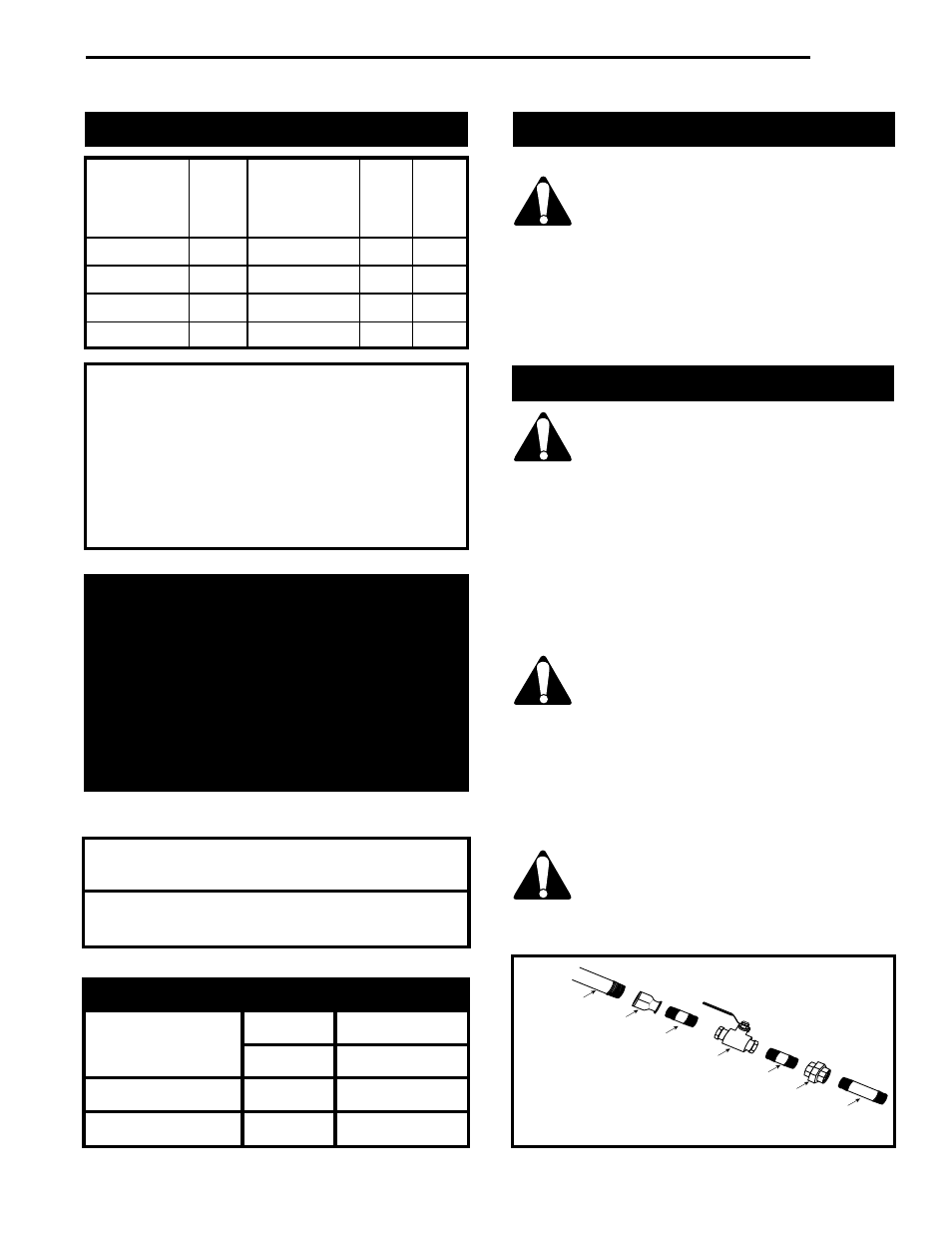

1/2" Gas Supply

1/2" X 3/8" Reducer

3/8" Nipple

3/8" Nipple

3/8" Nipple

3/8" X 3/8" Shut Off Valve

3/8" Union

TYPICAL GAS LINE CONNECTION

GAS SPECIFICATIONS

IRFSDV24/IRFSDV34

CERTIFIED TO

ANSI Z21.88b-1999 / CSA 2.33b-M99

Vented Gas Fireplace Heaters

GAS INLET AND MANIFOLD PRESSURES

PREPARATION

GAS LINE INSTALLATION

The use of wall paper adjacent to this

fireplace is not recommended, as the

high heat given off by this fireplace may

adversely affect the binders in the

adhesive used to apply the wallpaper.

Before beginning, remove the window frame assembly

from the fireplace. Also check to make sure there is not

hidden damage to the fireplace. Take a minute and

plan out the gas, vent and electrical supply. See

Window Frame Assembly Section.

When purging the gas line, the front

glass must be removed.

The gas pipeline can be brought in through the rear of

the fireplace as well as the bottom. Opening is provided

on the bottom behind the valve to allow for the gas pipe

installation and testing of any gas connecion. It is most

convenient to bring the gas line in from the rear right

side of the valve, as this allows fan installation or

removal without disconnecting the gas line.

The gas line connection can be made

with properly tinned 3/8” copper tubing,

3/8” rigid pipe or an approved flex con-

nector. Since some municipalities have

some additional local codes, it is always

best to consult your local authority and

the CSA-B149 (.1 or .2) installation code.

For USA Installations consult the current

National Fuel Gas Code, ANSI Z223.1.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The gas control is equipped with a

captured screw type pressure test point,

therefore it is not necessary to provide a

1/8” test point up stream of the control.

This appliance may be installed in an aftermarket

permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a

certified kit is available and used.

Fig. 2

Input ratings are shown in BTU per hour and

are certified without deration for elevations up

to 4,500 feet (1,370 m) above sea level.

For elevations above 4,500 feet (1,370 m) in

USA, installations must be in accordance with

the current ANSI Z223.1 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or

local authorities having jurisdiction for install-

ations at elevations above 4,500 feet (1,370 m).

CFM186