Clearances for maintenance, Piping applications – CCI Thermal Technologies HP - High Pressure Heat Exchanger Unit Heater User Manual

Page 5

5

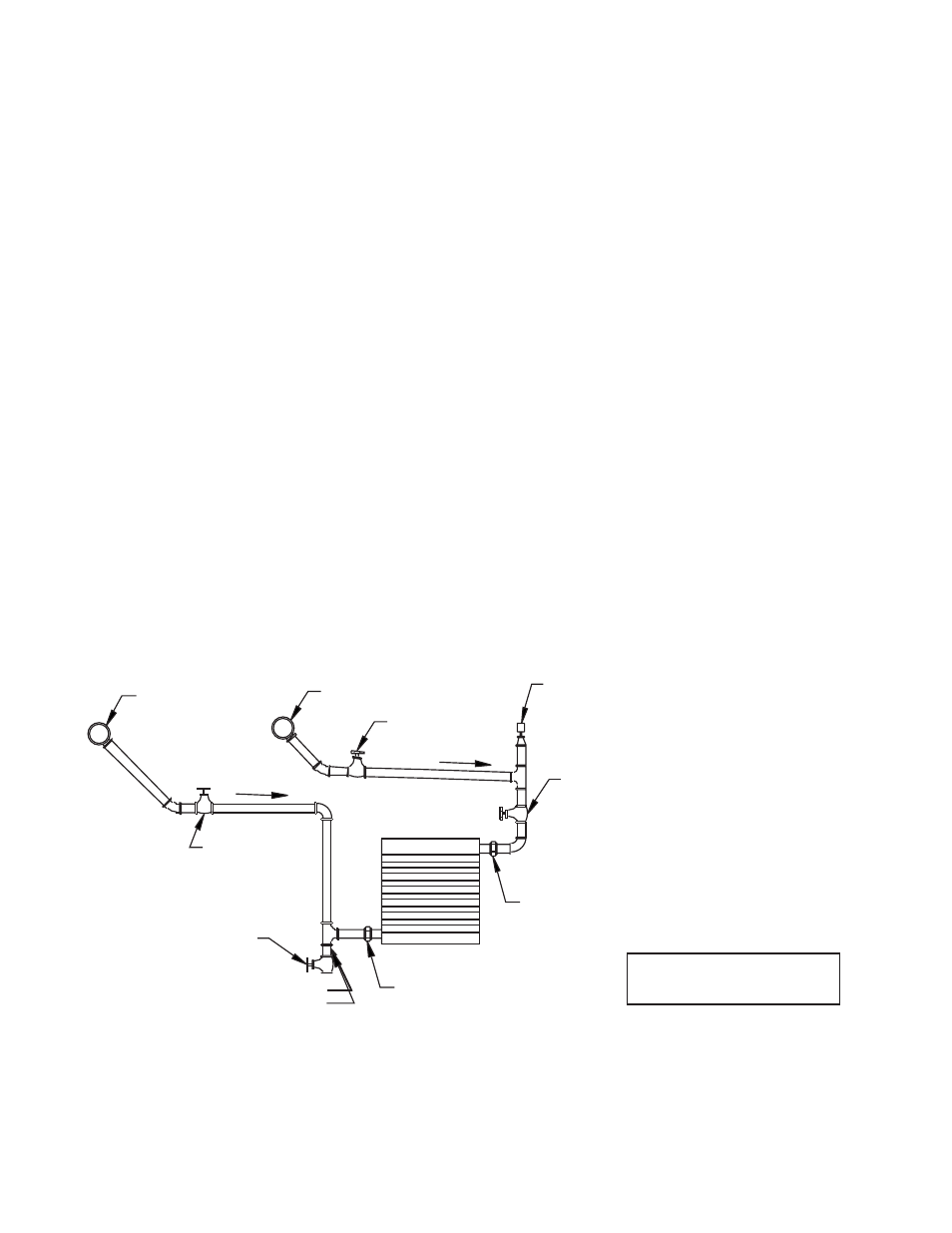

4

SHUT-OFF VALVE

PITCH DOWN

UNION

6 in. (152 mm) LONG

FULL SIZE

DIRT POCKET

RETURN

SUPPLY

PITCH DOWN

DRAIN VALVE

AUTOMATIC

AIR VENT

OR

PETCOCK.

SHUT-OFF VALVE

BALANCING

VALVE

UNION

Where heaters are installed in applications that are of a relocatable or transportable nature such as land or offshore drilling

rigs, an adequate mounting structure should be supplied to withstand all probable load conditions. Such load conditions

should recognize abuse situations such as truck off-loading impacts, etc. It is recommended that lock washers be used

beneath the bolt heads for these installations.

Heaters may be mounted at any reasonable height above floor level depending on the purpose of the heater. When

equipment is placed in a seldomly occupied building, the heaters may be placed at a low level. When heaters are required

to ensure personnel comfort, they should be mounted overhead. Typically, mounting heights range from 7 1/2 feet to 12

feet. All Ruffneck™ heaters have louvers installed that allow air flow to be directed from horizontal to 60 degrees or greater

downward deflection. Louvers should never be set to within less than 15 degrees of the closed position.

CLEARANCES FOR MAINTENANCE

It is important to provide adequate clearance around the heater for servicing. Allow enough space to permit easy fan or

motor replacement. Do not position the back of the fan motor against a surface, as air for the cooling fan will be blocked. It

is advisable to leave at least 2” clearance between the rear of the motor and the nearest obstruction. For easy removal of

the heat exchanger core assembly, it is important to leave clearance beneath the heater equal to the height of the heater

cabinet plus two inches.

PIPING APPLICATIONS

The following piping application and arrangements are only suggestions. Since it is impractical to cover all possible

applications, please refer to detailed piping references for more information.

Below are suggested piping arrangements.

FIG.1

UNIT HEATER

CONNECTIONS TO

OVERHEAD

FLUID MAINS

NOTES:

1. Do not use with fluids corrosive to steel

2. Install using proper piping practices.

Where heaters are installed in applications that are of a relocating or transportable nature such as land or offshore drilling

rigs, an adequate mounting structure should be supplied to withstand all probable load conditions. Such load conditions

should recognize abuse situations such as truck off-loading impacts, etc. It is recommended that lock washers be used

beneath the bolt heads for these installations.

Heaters may be mounted at any reasonable height above floor level depending on the purpose of the heater. When

equipment is placed in a seldom occupied building, the heaters may be placed at a low level. When heaters are required

to ensure personnel comfort, they should be mounted overhead. Typically, mounting heights range from 7 1/2 feet to 12

feet. Heaters CSA certified must be mounted at a minimum height of 7.9 ft (2.4 m) above the floor. All Ruffneck™ heaters

have louvers installed that allow air flow to be directed from horizontal to 60 degrees or greater downward deflection.

Louvers should never be set to within less than 15 degrees of the closed position.

CLEARANCES FOR MAINTENANCE

It is important to provide adequate clearance around the heater for servicing. Allow enough space to permit easy fan or

motor replacement. Do not position the back of the fan motor against a surface, as air for the cooling fan will be blocked. It

is advisable to leave at least 2” clearance between the rear of the motor and the nearest obstruction. For easy removal of

the heat exchanger core assembly, it is important to leave clearance beneath the heater equal to the height of the heater

cabinet plus two inches.

PIPING APPLICATIONS

The following piping application and arrangements are only suggestions. Since it is impractical to cover all possible

applications, please refer to detailed piping references for more information.

Below are suggested piping arrangements.